Radio frequency identification antenna and preparation method thereof

A radio frequency identification and antenna technology, applied in the field of radio frequency identification antenna and its preparation, can solve the problems of easy tearing of PET base material, unsatisfactory anti-transfer, difficult production process, high cost of precious metal silver, etc., so as to shorten the drying time and ensure The effect of adhesion and short curing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

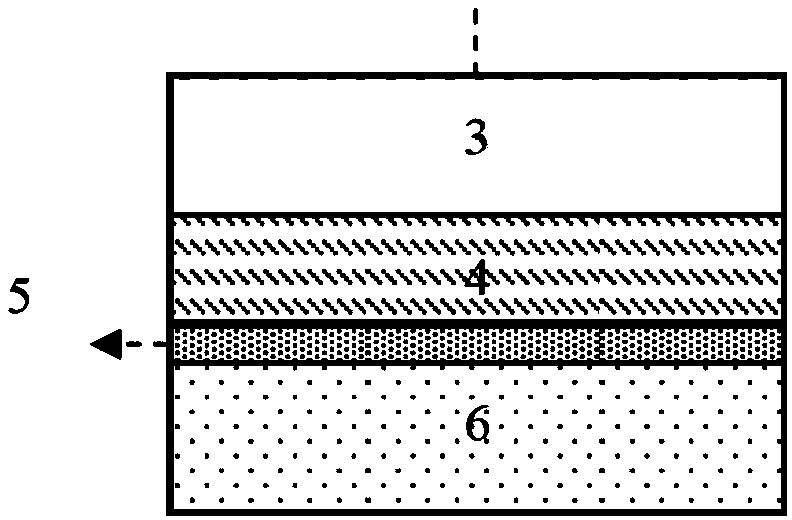

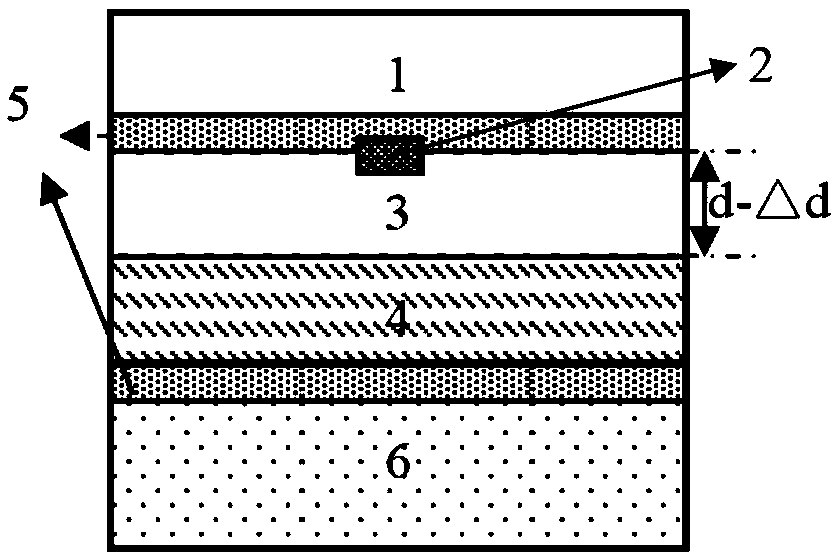

[0036] A radio frequency identification antenna in this embodiment includes a fragile paper substrate 4 and an antenna pattern 3, the bottom surface of the fragile paper substrate 4 is coated with glue 5; the antenna pattern 3 is printed by photocuring with conductive ink And compacted on the fragile paper substrate 4; the conductive ink (#1) includes the following components by weight: 6 parts of graphene nanosheets with a sheet size of 2 to 5 μm, and silver particles with a particle size of 1 to 2 μm 52 parts of particles, 22 parts of epoxy acrylic resin as matrix prepolymer, 13 parts of alcohol acrylate as reactive diluent monomer, 4 parts of photoinitiator, 0.2 part of photosensitizer, 0.3 part of coupling agent, 0.5 part of dispersant, auxiliary 2 doses. The auxiliaries include leveling agents.

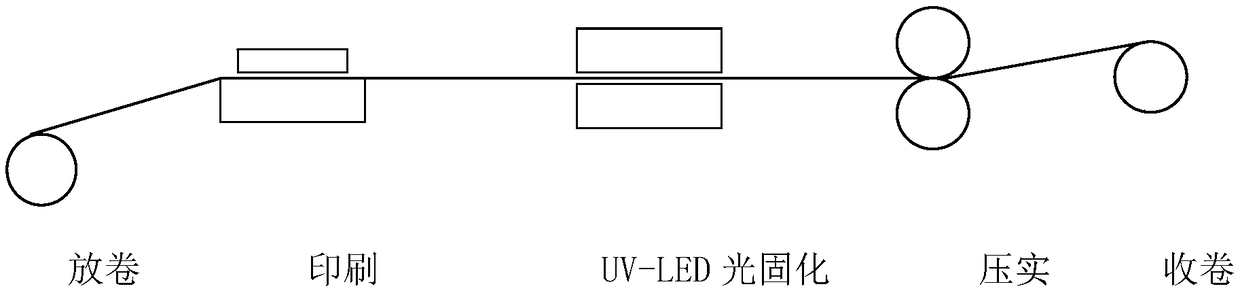

[0037] Above-mentioned a kind of radio frequency identification antenna preparation method, comprises the following steps:

[0038](1) Preparation of conductive ink: Weigh the ...

Embodiment 2

[0049] The difference between Example 2 and Example 1 is that the conductive ink (#2) includes the following components in parts by weight: 3 parts of graphene nanosheets with a sheet size of 5-10 μm, and silver particles with a particle size of 0.1-1 μm. 48 parts of particles, 20 parts of polyurethane acrylic resin as the matrix prepolymer, 15 parts of neopentyl glycol diacrylate (TPGDA) as the reactive diluent monomer, 2.5 parts of photoinitiators 184 and 369, 0.2 parts of photosensitizer thioxanthone parts, 0.3 parts of coupling agent, 0.5 parts of dispersant, 2 parts of auxiliary agent.

[0050] A method for preparing a radio frequency identification antenna in this embodiment includes the following steps:

[0051] (1) Preparation of conductive ink: Weigh the matrix prepolymer and active diluent monomer according to the above mass, add the weighed graphene nanosheets and silver particles in turn for stirring and dispersing, then add dispersant and coupling agent to continu...

Embodiment 3

[0056] The difference between Example 3 and Example 1 is that the conductive ink (#3) includes the following components by weight: 5 parts of graphene nanosheets with a sheet size of 2 to 5 μm, and silver particles with a particle size of 2 to 5 μm. 45 parts of particles, 24 parts of polyether acrylate as matrix prepolymer, 7 parts of reactive diluent monomers of lauryl acrylate and tetrahydrofuryl acrylate, 2.5 parts of photoinitiators DETX and ITX, photosensitizer 4-methyldiphenyl 0.2 parts of ketone, 0.2 parts of coupling agent, 0.6 parts of dispersant, 2 parts of auxiliary agents such as leveling agent.

[0057] A method for preparing a radio frequency identification antenna in this embodiment includes the following steps:

[0058] (1) Preparation of conductive ink: Weigh the matrix prepolymer and active diluent monomer according to the above mass, add the weighed graphene nanosheets and silver particles in turn for stirring and dispersing, then add dispersant and coupling...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com