Mineral modified magnesium-oxysulfate-based composite cementing material

A composite gelling material, magnesium oxysulfate-based technology, applied in the field of mineral modified magnesium oxysulfide-based composite gelling materials, to achieve the effect of delaying the hydration process, reducing the heat of hydration, good mechanical performance stability and water resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~ Embodiment 6 and comparative example 1~ comparative example 6

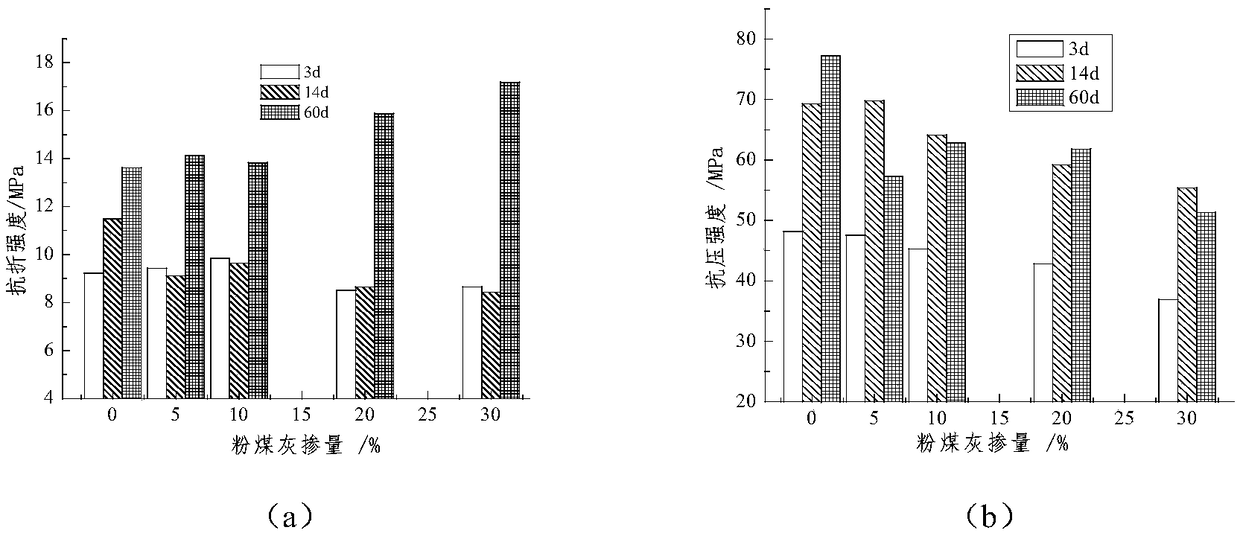

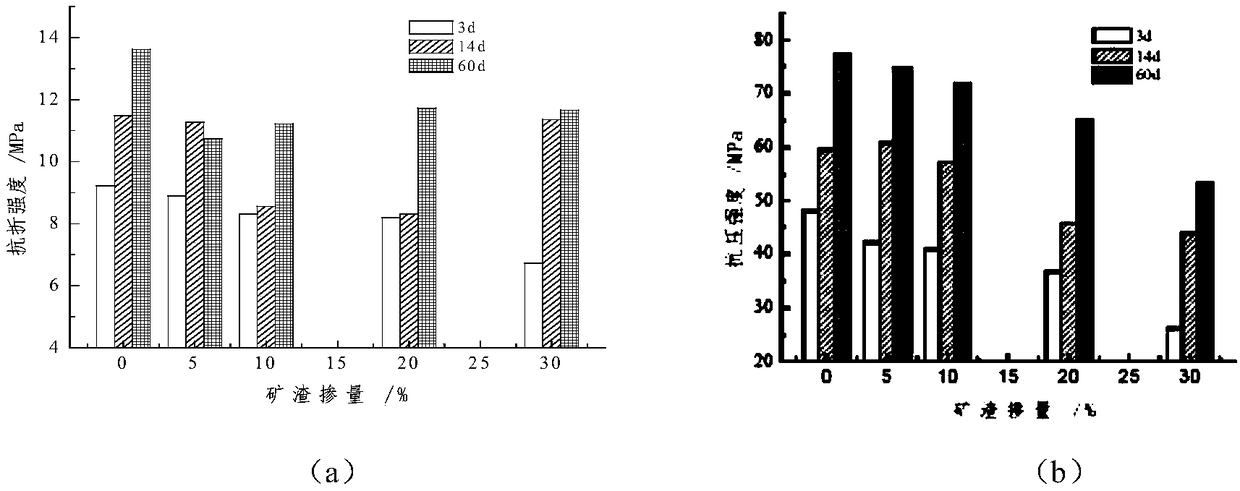

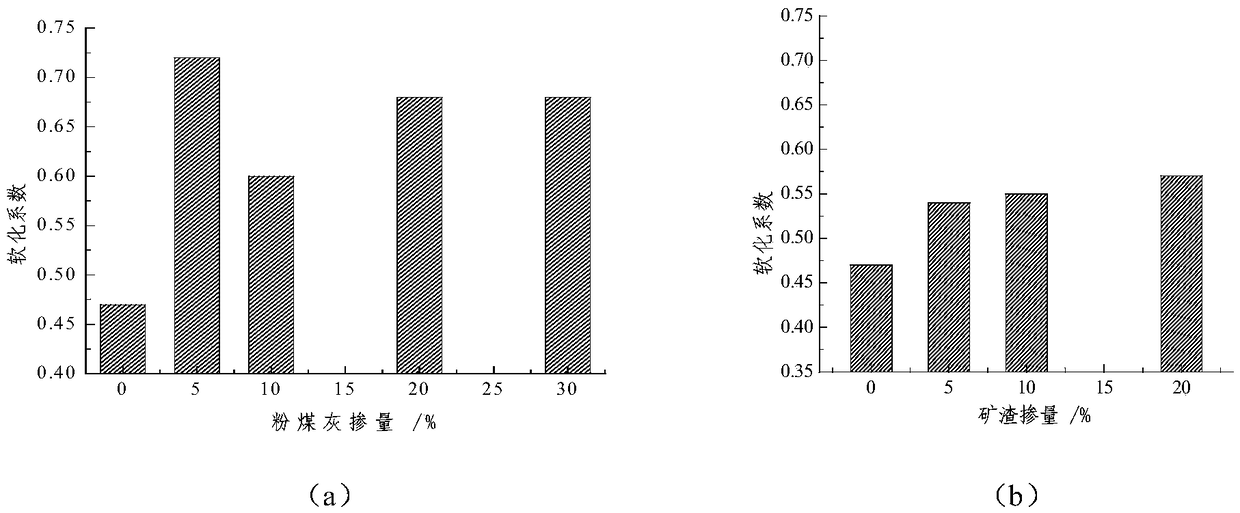

[0026] Embodiment 1~embodiment 6 and comparative example 1~comparative example 6 select for use: Tianjin produces technical grade magnesium sulfate heptahydrate (its specific composition is shown in Table 2); Yingkou produces lightly burned magnesium oxide powder (its specific composition is shown in Table 3) , the particle size of the light-burned magnesium oxide powder is concentrated in 0.76-0.85 μm; II grade fly ash; S95 slag (also known as slag).

[0027] The chemical composition of table 2 magnesium sulfate heptahydrate

[0028]

[0029] The chemical composition of table 3 light-burned magnesia

[0030]

[0031] If the parts by weight of light-burned magnesia powder in the cementitious material listed in Table 1 is marked as x, the parts by weight of citric acid modifier (i.e. citric acid or the mixture of citric acid and water glass) is marked as y, mineral The parts by weight of modifying agent (i.e. fly ash or slag powder) is recorded as z, with the numerical v...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com