A kind of cement clinker, cement clinker preparation method and anti-shrinkage cracking low-heat Portland cement

A technology of Portland cement and cement clinker, applied in the field of cement minerals, can solve the problems of unstable physical and chemical properties of hydration products, uncontrollable expansion process, failure to achieve energy saving and environmental protection, etc., to reduce shrinkage cracking problems and compensate for The effect of volume shrinkage deformation and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

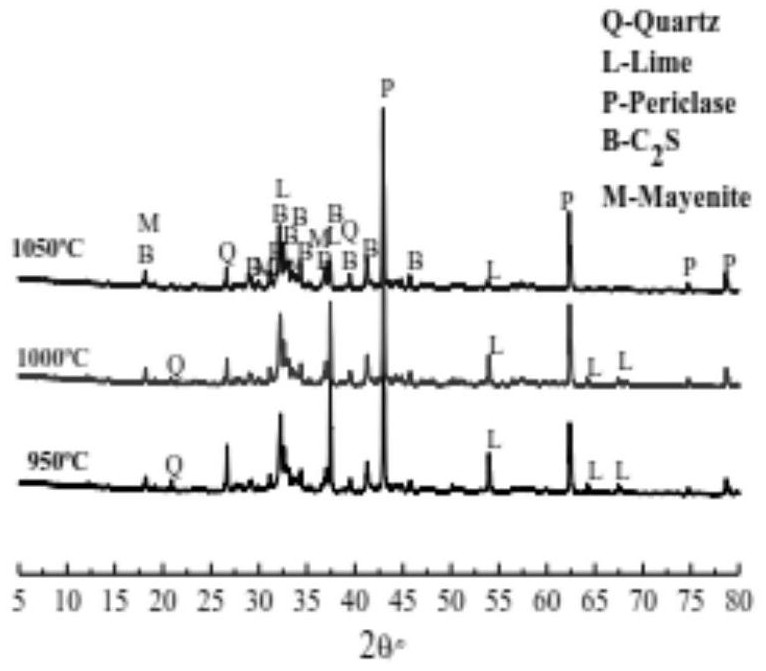

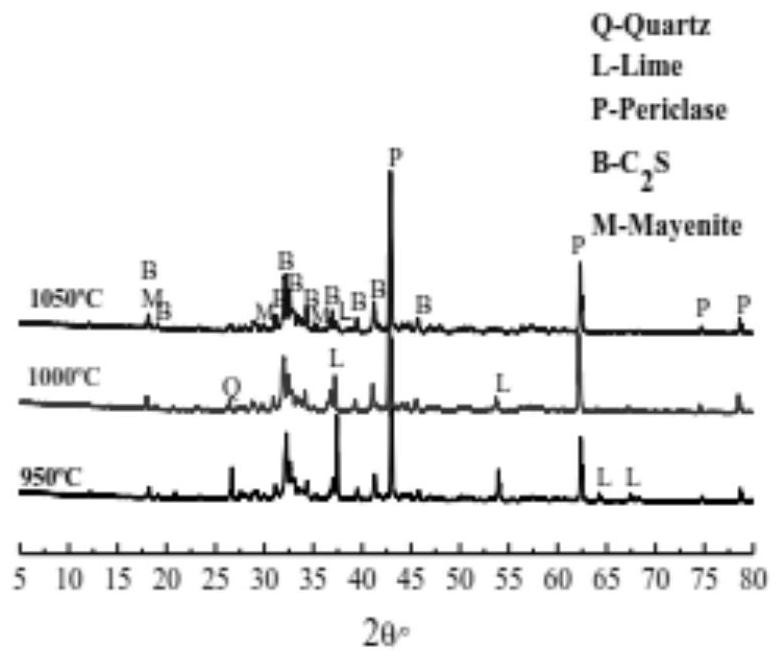

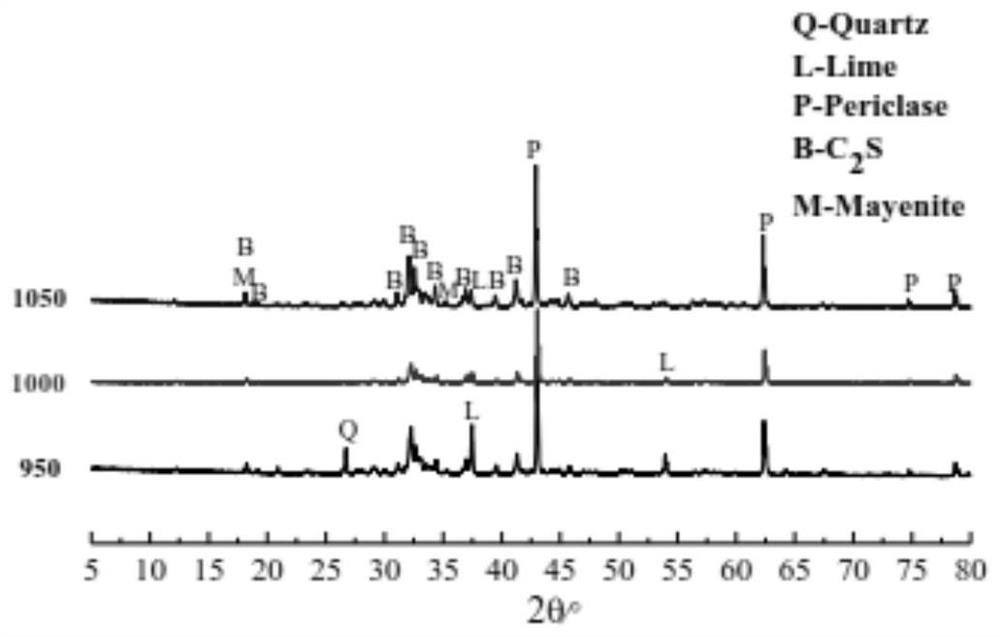

Image

Examples

Embodiment 1

[0054] A new type of cement clinker preparation method

[0055] The chemical composition of the raw materials used in the experiment is shown in Table 1.

[0056] Table 1 Chemistry of raw materials

[0057] raw material Loss SiO 2

CaO MgO Fe 2 O 3

Al 2 O 3

SO 3

Total dolomite 46.80 1.55 29.46 21.03 0.26 0.47 — 99.57 clay 8.00 61.74 2.71 2.46 5.90 14.27 — 95.08

[0058] a) Separate the raw material dolomite (MgO mass content greater than 20%) and clay (SiO 2 mass content greater than 50%) drying, crushing and grinding until all pass through a 0.08mm sieve to obtain dolomite grinding and clay grinding for use. Then, after mixing the spare dolomite and clay powder according to the ratio calculated by mass (dolomite:clay=421:100), add 1% CaF of raw material mass fraction. 2 , mixed on the mixer for 24h. Take about 50g of material each time, add 4% water in the mass fraction of the raw material, hold th...

Embodiment 2

[0062] The difference from Example 1 is that the calcination temperature is 950° C. and the holding time is 1 h.

Embodiment 3

[0064] The difference from Example 1 is that the calcination temperature is 950°C and the holding time is 2h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| sand rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com