Method for preparing polycarboxylic acid slump-retaining agent by atom transfer radical polymerization

A technology of atom transfer and polymerization, applied in the field of polycarboxylate slump inhibitors for cement concrete, can solve the problems of wide molecular weight distribution, cumbersome operation, complex process, etc., reduce the peak calorific value, improve application performance, delay water The effect of the process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

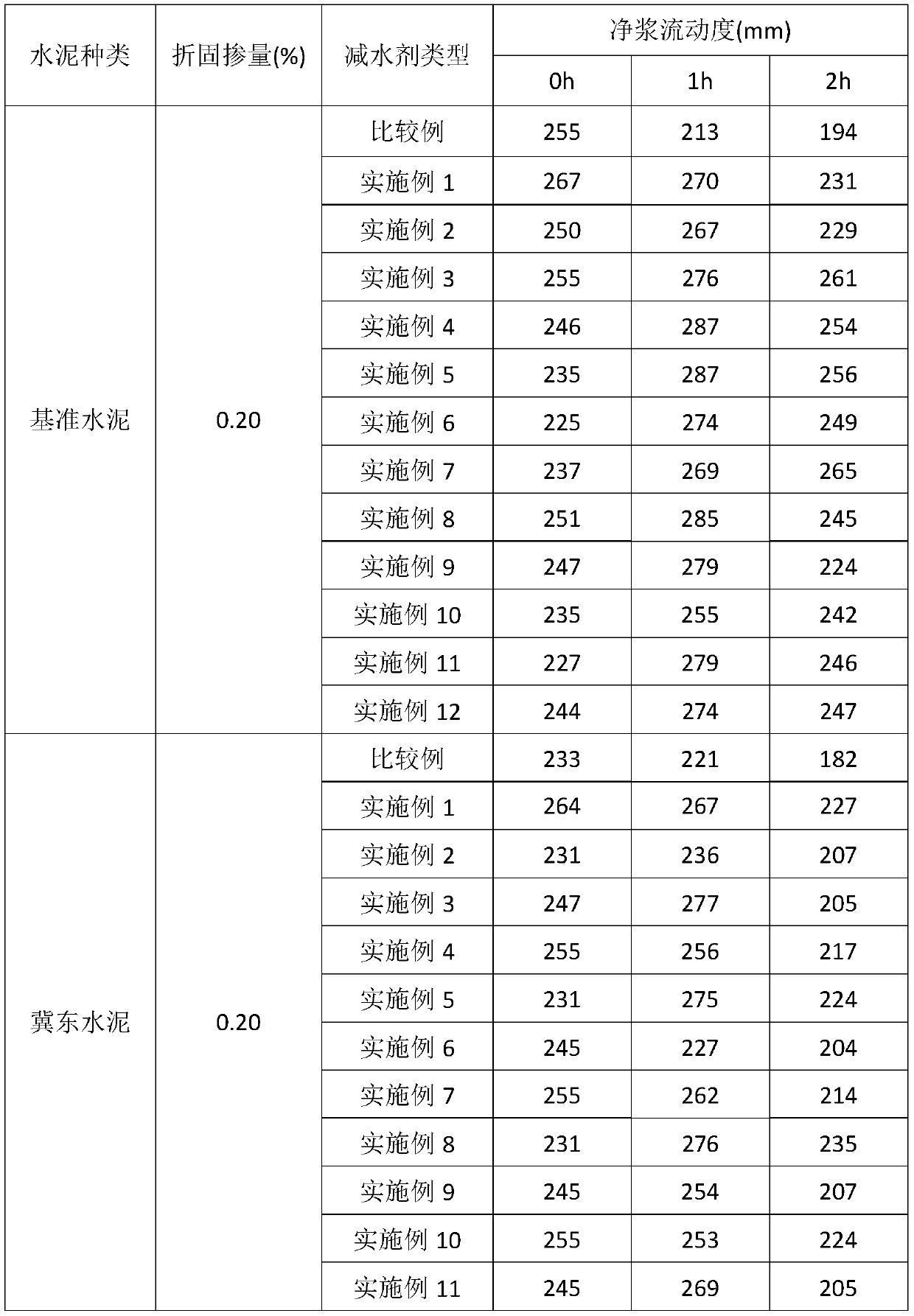

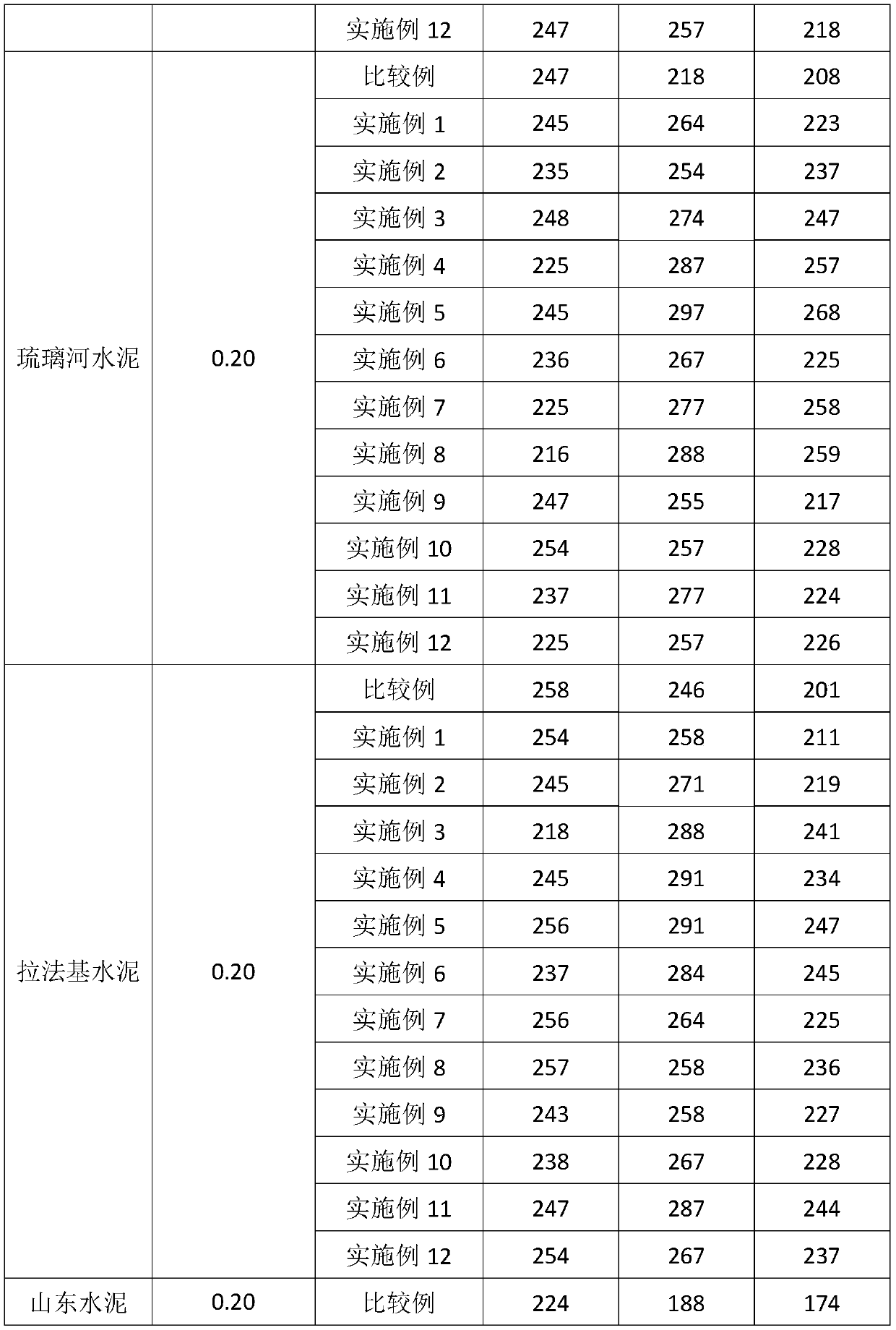

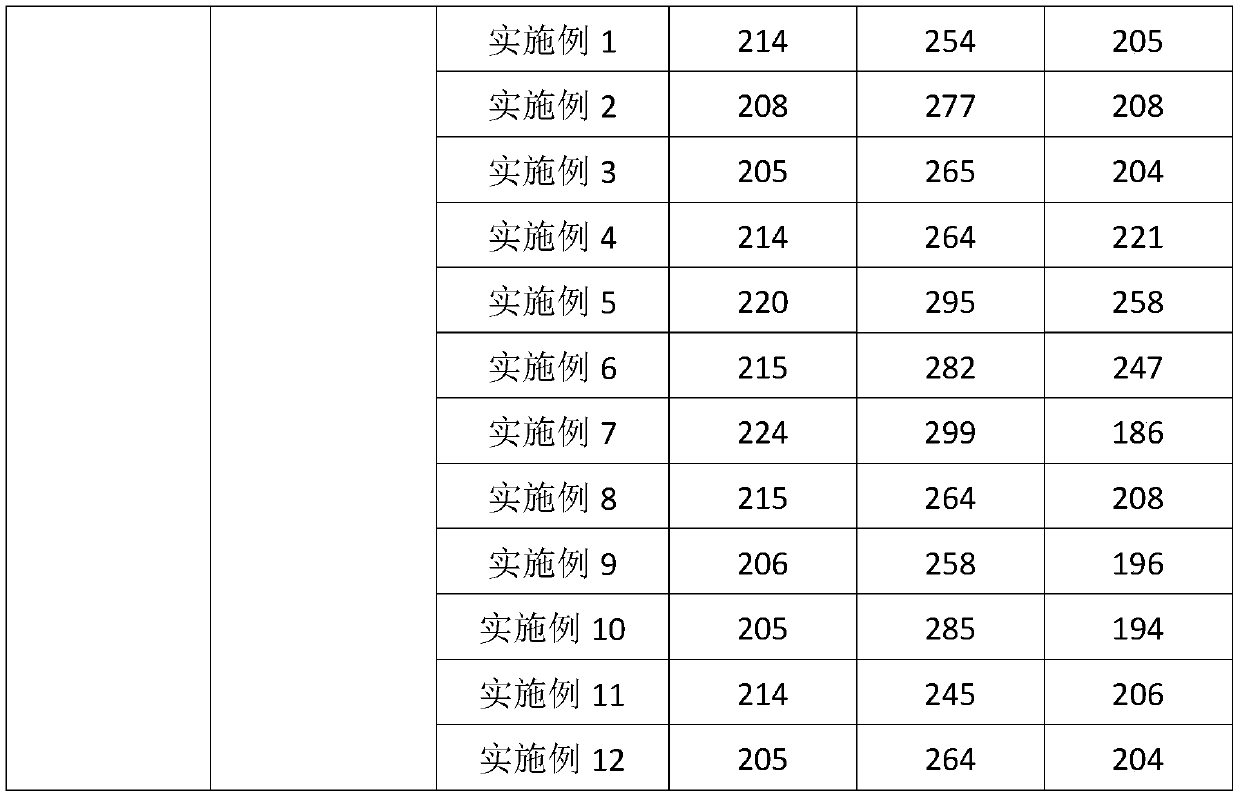

Examples

Embodiment 1

[0025] First, fill the reactor with nitrogen for 3 times, continue to fill the reactor with nitrogen after excluding oxygen to maintain the nitrogen atmosphere in the reactor, and then add 7.1g of acrylamide, 7.1g of toluene, 0.16g of 2,2-bipyridine, 0.14g of bromide Cuprous, 0.2g ethyl 2-bromopropionate, and stirred for 5 minutes during each addition, heated up to 90°C for atom transfer radical polymerization, and reacted for 5 hours to obtain a macromonomer initiator; 50g methoxy Add methoxypolyethylene glycol (molecular weight = 500) into the reactor, raise the temperature to 70°C, and when the methoxypolyethylene glycol is in a liquid state, add 0.5g hydroquinone, 14.4g acrylic acid, 6.44 g of p-toluenesulfonic acid, and the stirring time is 5 minutes at a time between each feeding, and 40 g of cyclohexane is added when the temperature rises to 100° C., and the esterification reaction is carried out at 150° C., and the reaction obtained water is separated during the reactio...

Embodiment 2

[0027] After the polycarboxylate slump-retaining agent with a concentration of 40% obtained in Example 1 was stored at 8° C. for 30 days, its implementation effect was measured.

Embodiment 3

[0029] First, fill the reactor with nitrogen 4 times, and continue to fill the reactor with nitrogen after excluding oxygen to keep the reactor in a nitrogen atmosphere, then add 8.51g of methacrylamide, 17.02g of xylene, and 0.25g of pentamethyldiethylenetriamine in sequence , 0.2g cuprous chloride, 0.23g methyl 2-bromopropionate, and stirred for 10 minutes during each addition, heated up to 80°C to carry out atom transfer radical polymerization, and reacted for 6 hours to obtain a macromonomer initiator ; 100g of methoxypolyethylene glycol (molecular weight=1000) was added to the reactor, and the temperature was raised to 60°C. When the methoxypolyethylene glycol was in liquid state, 0.3g of phenothiazine, 25.8 g methacrylic acid, 2.58g methyl acrylate, 6.25g phosphoric acid, and the stirring time between each feeding is 10 minutes. When the temperature rises to 90°C, 20.6g benzene is added, and the temperature is continued to rise to 140°C for esterification reaction. Simul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com