C115-C140 ultra-high-performance self-compacting concrete for offshore wind power floating type foundation

A technology of self-compacting concrete and offshore wind power, applied in the field of building materials, can solve problems such as hydration heat and construction problems of large-volume structures, shrinkage crack control problems, durability problems of giant components, restrictions on wide application, slow flow rates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

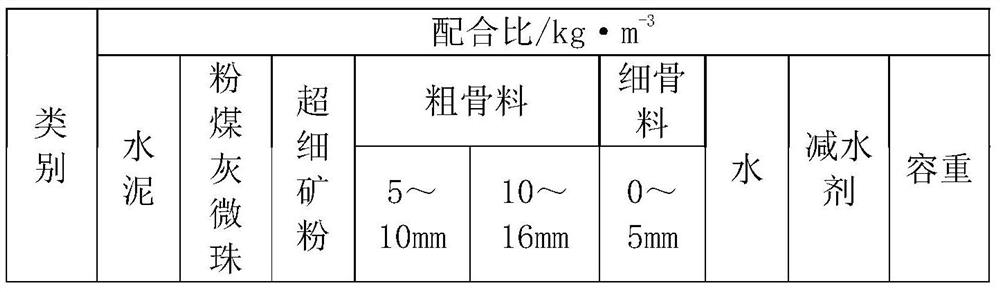

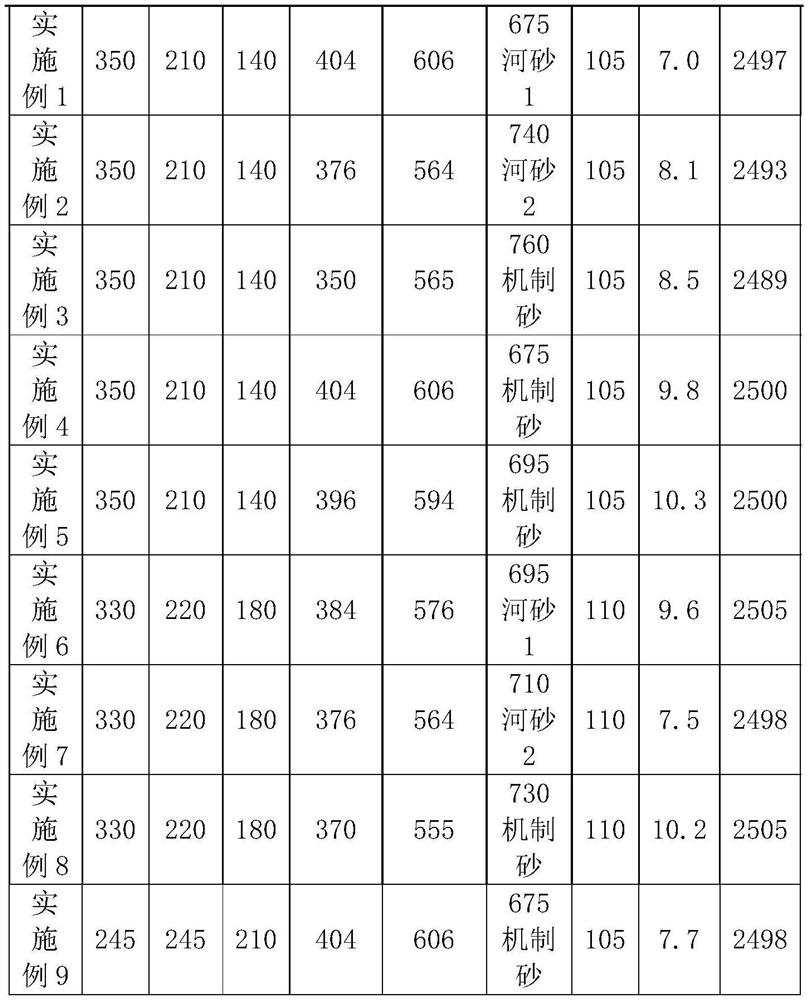

[0035] Embodiments of the present invention will be described in detail below in conjunction with examples, but those skilled in the art will understand that the following examples are only for illustrating the present invention, and should not be considered as limiting the scope of the present invention.

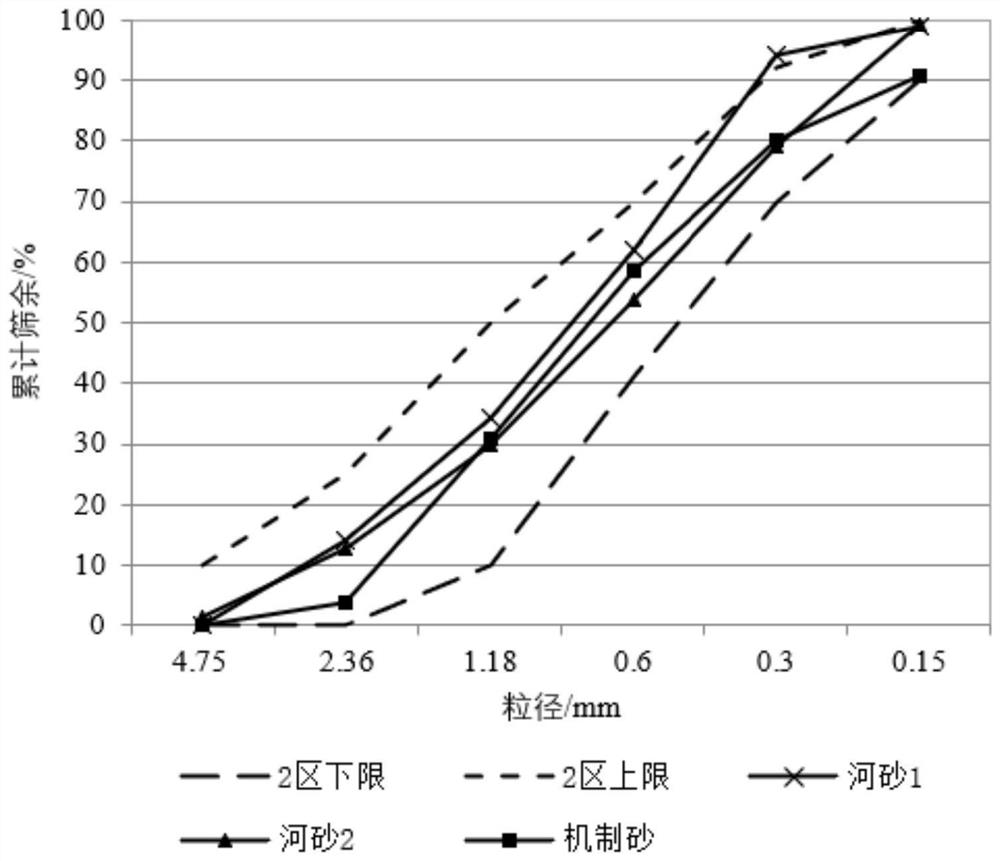

[0036] In the following examples, the raw material parameters adopted are as follows:

[0037] The water consumption of the standard consistency of cement is not more than 28.0%, and the specific surface area is not more than 380m 2 / kg, 3-day compressive strength not less than 33MPa, 28-day strength not less than 58MPa, C 3 The A content is not more than 8.0%, and the heat of hydration in 3 days is not more than 300J / g.

[0038] The highly active ultrafine powder is a mixture of fly ash microbeads, ultrafine mineral powder or fly ash microbeads, ultrafine mineral powder and silica fume. The median diameter of fly ash microbeads is less than 3 μm, the water demand ratio i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com