Modified calcium carbonate for floor tiles and preparation method thereof

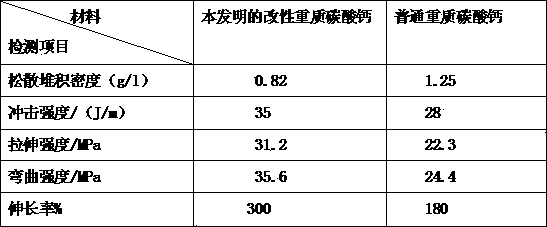

A technology of calcium carbonate and floor tiles, applied in chemical instruments and methods, fibrous fillers, inorganic pigment treatment, etc., can solve the problems of composite material performance degradation, weak matrix bonding force, two-phase interface defects, etc., to improve heat insulation Good performance, dispersion and compatibility, uniform particle size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] A kind of preparation method of modified calcium carbonate for floor tiles,

[0014] First weigh 400 mesh heavy calcium carbonate 100, magnesium oxide 0.3, sodium tripolyphosphate 0.2, silane coupling agent KH5500.1, fatty acid glyceride 3, beryllium oxide 0.4, EVA resin 2, molybdenum oxide 0.3 by weight (kg). , hollow glass microsphere 0.6, bamboo charcoal fiber 1, then prepare according to the following steps:

[0015] (1) First, mix heavy calcium carbonate and magnesium oxide evenly, then dry at 90-100°C until the water content is below 0.5%, and then add it to a high-speed mixer;

[0016] (2) Mix sodium tripolyphosphate, silane coupling agent KH550, fatty acid glycerides, beryllium oxide, and EVA resin first, and then add them to calcium carbonate, at a temperature of 85-90°C, at a speed of 900-1000 rpm , stirring at high speed for 5-6 minutes;

[0017] (3) Add the remaining materials molybdenum oxide, hollow glass microspheres, and bamboo charcoal fibers to the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com