Heat-flow meter for measuring heat flux of aluminium oxide inside solid rocket engine dynamically in real-time

A real-time measurement, solid rocket technology, used in engine testing, heat measurement, calorimeters, etc., can solve problems such as inability to condensate particle scour or deposition heat flux density measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

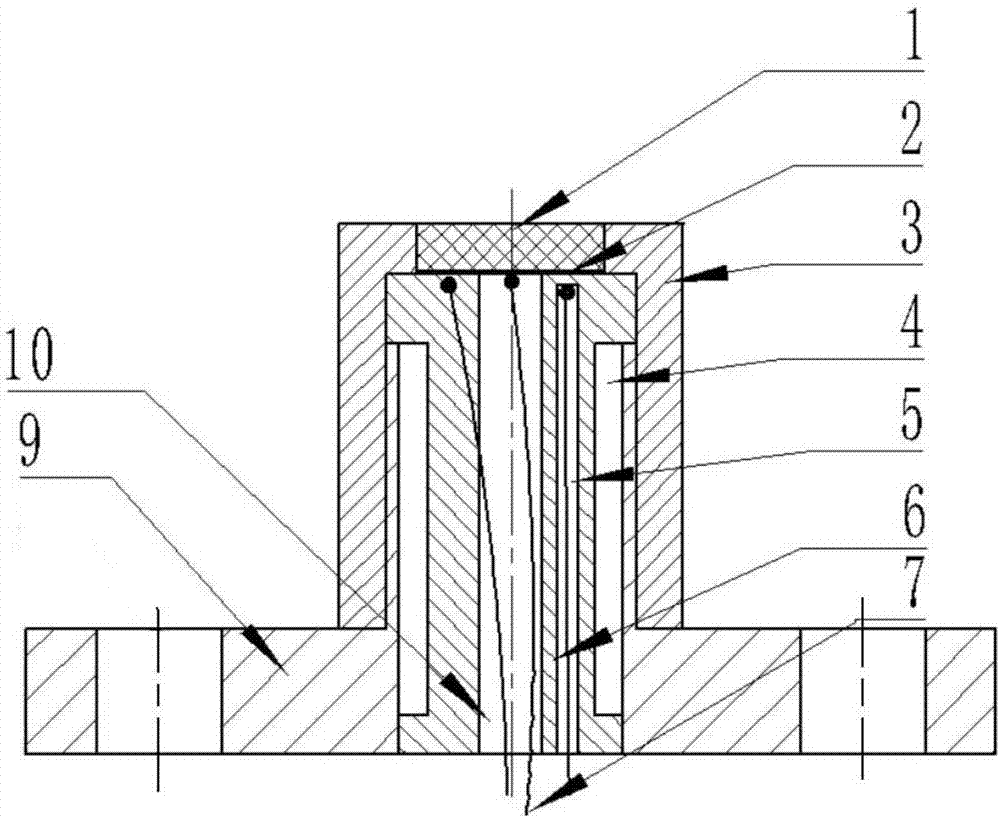

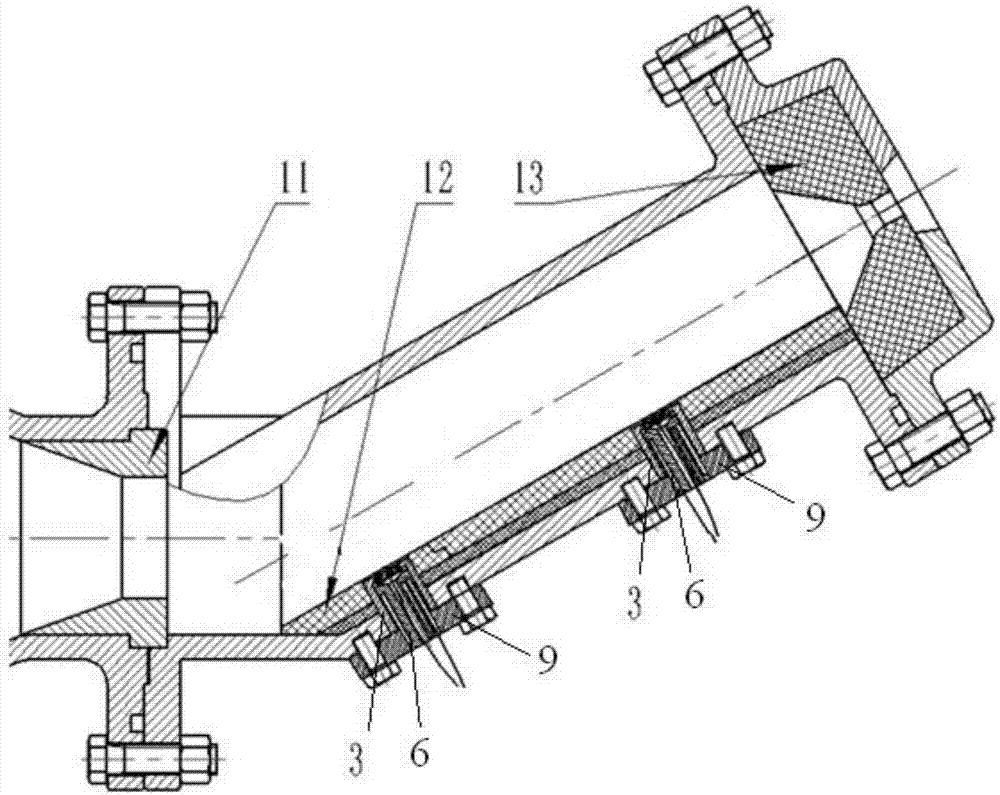

[0033] The thermal insulation ceramic disc 1 is a cylinder with a thickness of 2mm and an inner diameter of 10mm; the size parameters of the beryllium oxide ceramic shell 3 are: wall thickness 3mm, outer diameter 20mm, top inner diameter 10mm, main body inner diameter 16mm; heat sink copper 6 is an outer diameter of 16mm, A cylindrical sleeve structure with an inner diameter of 4mm; a continuous water cooling channel 4 with a width of 2mm and a depth of 2mm is opened on the outer surface of the heat sink copper 6, and a thermocouple 5 is installed inside the heat sink copper 6.

[0034] Wherein, the selection of the outer diameter of the heat sink copper 6 is determined by the inner diameter of the beryllium oxide ceramic shell 3, and the selection of the inner diameter is determined by the machining accuracy.

[0035] The heat-insulating ceramic disc 1 has alumina ceramics with low thermal conductivity, which is used to reduce the surface temperature of the constantan sheet 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com