Low-light-degradation and high-power LED street lamp and manufacturing method thereof

A technology for LED street lamps and LED bulbs, applied in circuits, light sources, electric light sources, etc., can solve the problems of inability to cool down LED lamps, shorten service life, and poor heat dissipation effect, and achieve improved cooling effect, work efficiency, and excellent cooling effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

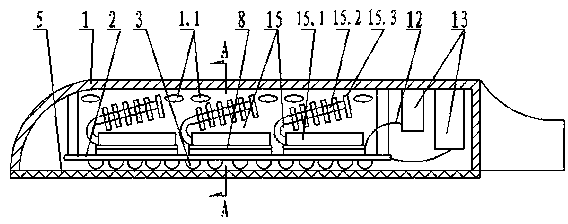

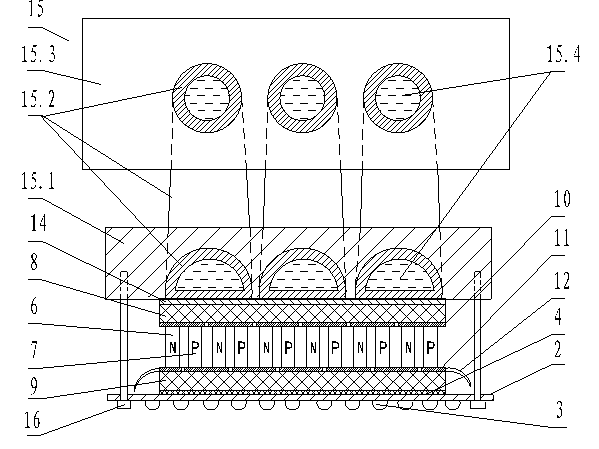

[0013] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0014] Embodiments of the present invention: a method for manufacturing a low-light decay high-power LED street lamp of the present invention includes using existing N-type semiconductor elements and P-type semiconductor elements as cooling elements to carry out a circuit board equipped with LED light-emitting diode bulbs. To dissipate heat and cool down, when using the existing N-type semiconductor elements and P-type semiconductor elements as refrigeration elements, the semiconductor ingot for making N-type semiconductor elements or P-type semiconductor elements is made in advance into a cone with a large diameter at one end and a small diameter at the other end Body-shaped ingot (the diameter of the small-diameter end of the conical ingot can be determined according to the needs of use, and its taper can be controlled between 2 and 5 degrees...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com