Low-temperature sintered ceramic material

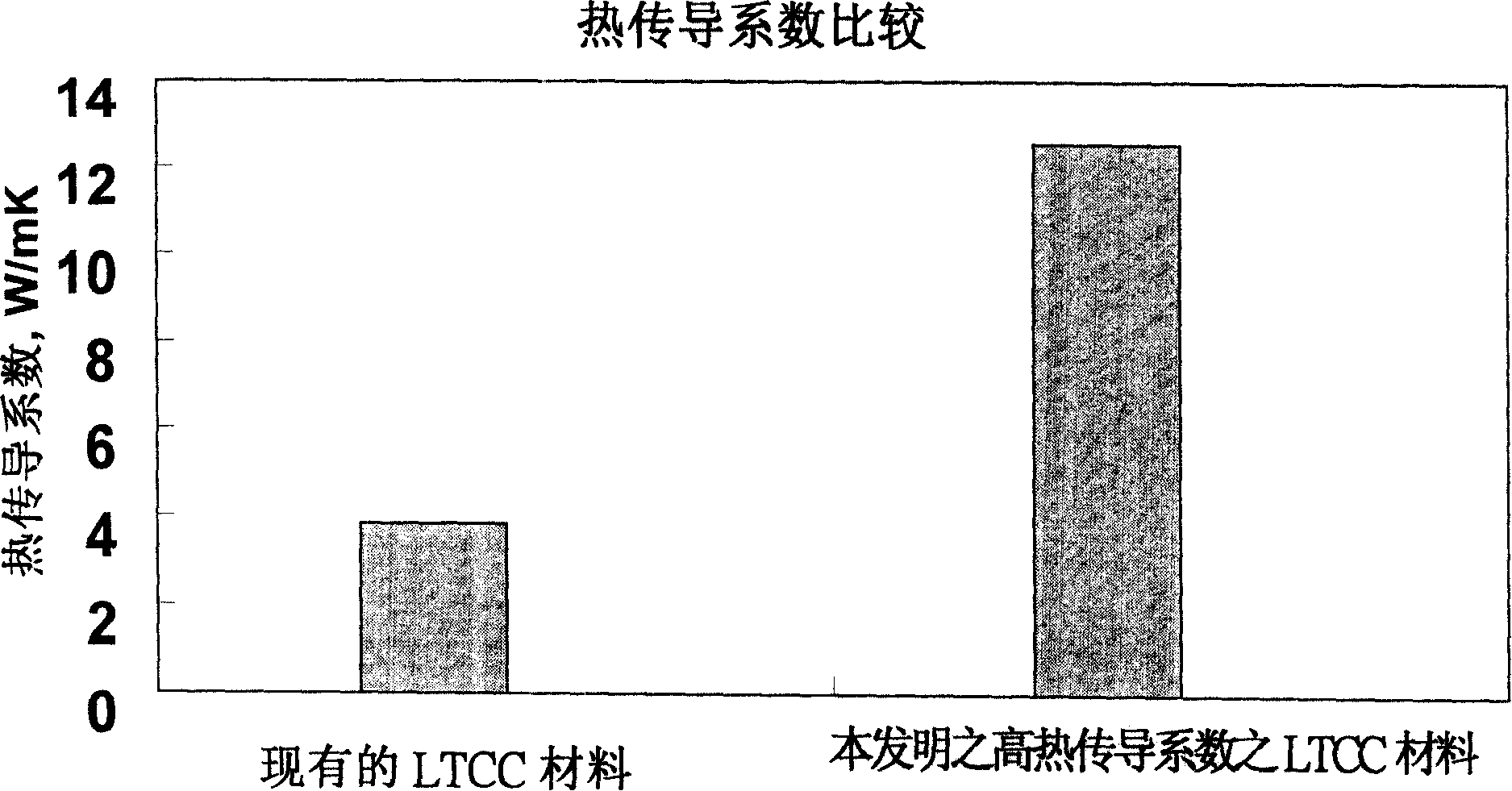

A technology of low-temperature co-fired ceramics and ceramic materials, applied in the field of low-temperature co-fired ceramic materials, can solve the problems of low thermal conductivity and low thermal conductivity, and achieve the effect of improving comprehensive performance and thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The low-temperature co-fired ceramic material with high thermal conductivity in one embodiment of the present invention measures 45%wt. glass powder and 55%wt. aluminum nitride. About 1.5mm ceramic green sheet, cut into appropriate size with a knife, and then sintered at 800°C for about 60 minutes to obtain a dense ceramic test piece.

Embodiment 2

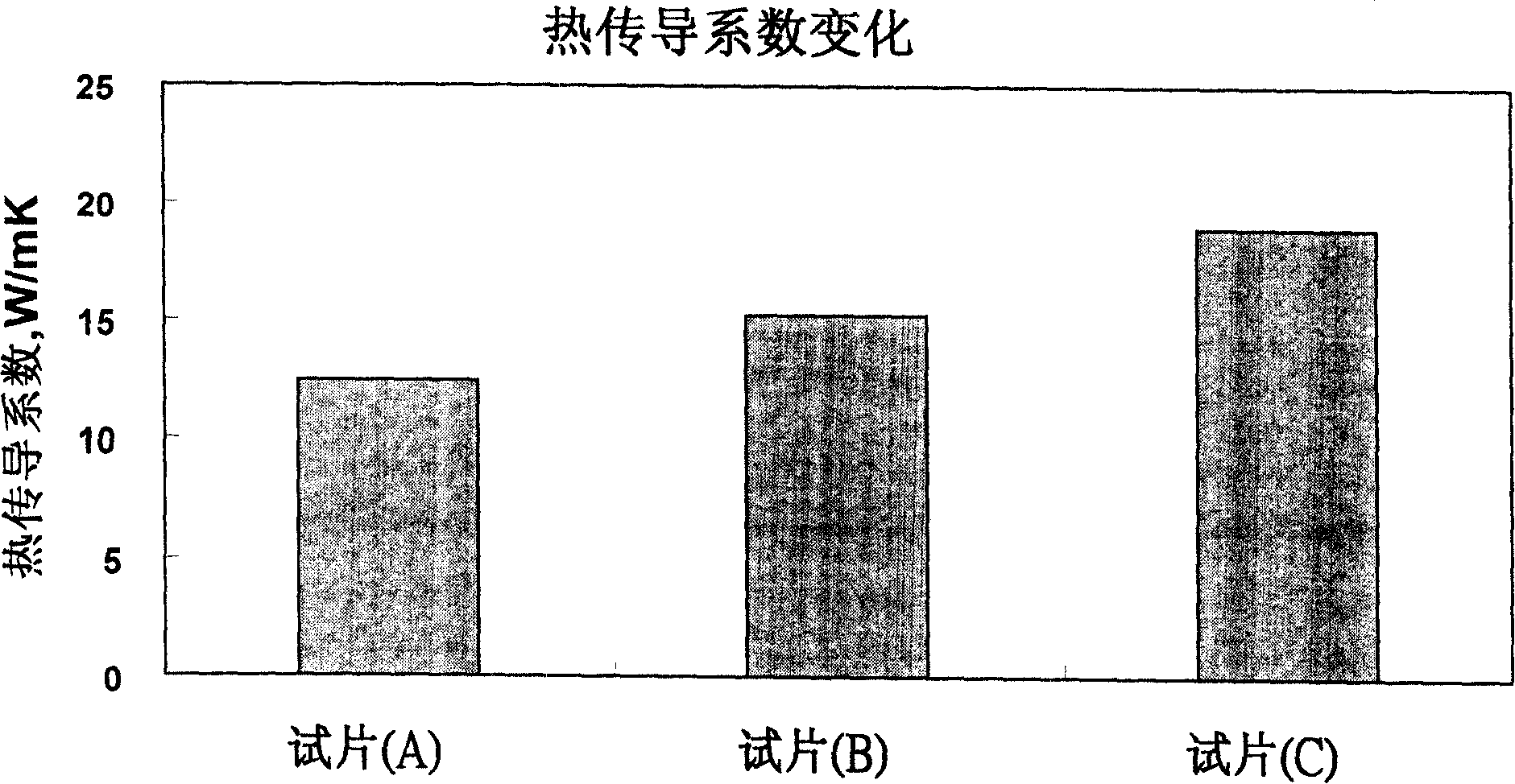

[0042] In another embodiment of the present invention, the low-temperature co-fired ceramic material with high thermal conductivity is made by measuring 45%wt. A ceramic green sheet with a thickness of about 1.5mm was cut into an appropriate size with a knife, and then sintered at 800°C for about 60 minutes to obtain a dense ceramic test piece (A).

Embodiment 3

[0044] The low temperature co-fired ceramic material with high thermal conductivity in another embodiment of the present invention is made by measuring 40%wt. A ceramic green sheet with a thickness of about 1.5mm was cut into an appropriate size with a knife, and then sintered at 800°C for about 60 minutes to obtain a dense ceramic test piece (B).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com