Patents

Literature

44results about How to "Effectively wash off" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

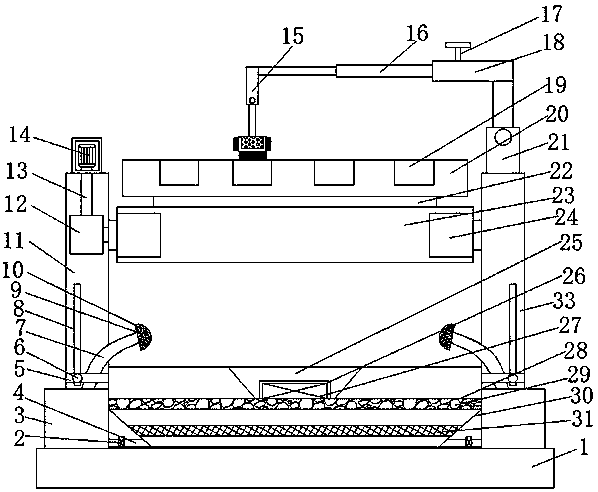

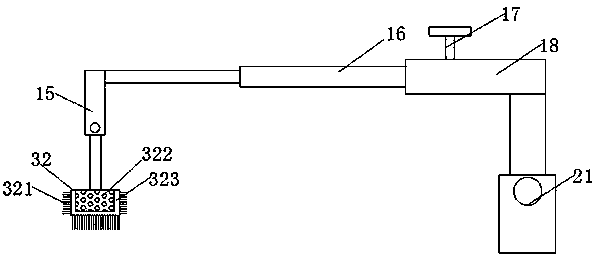

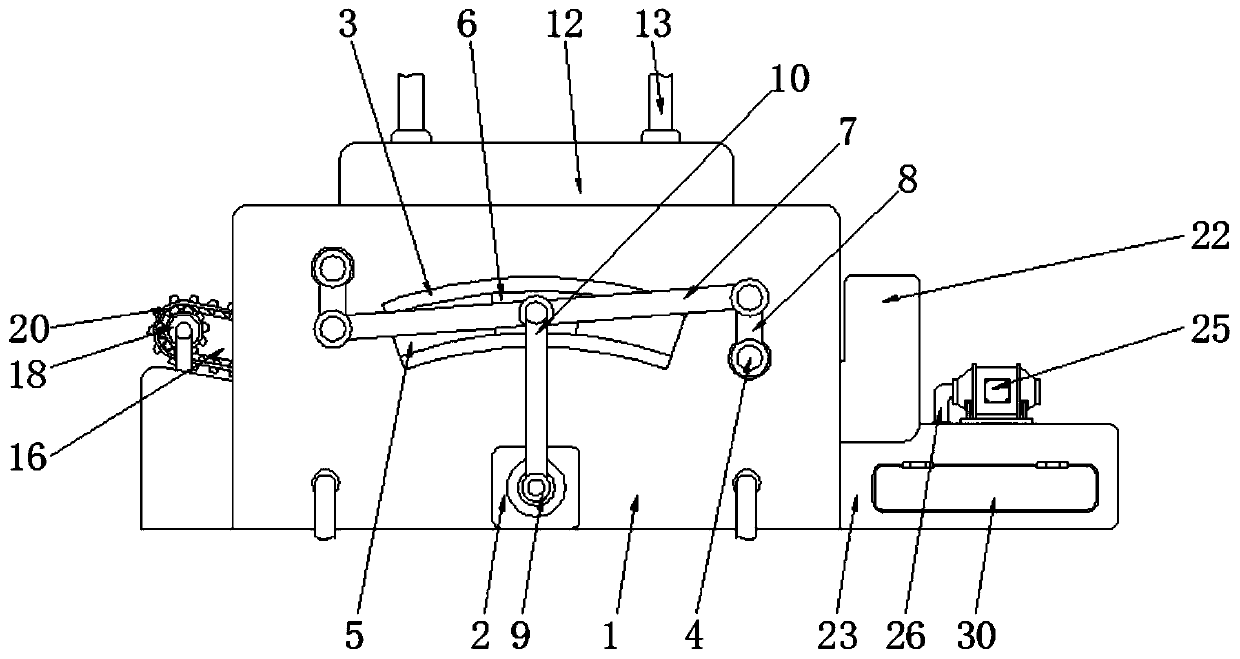

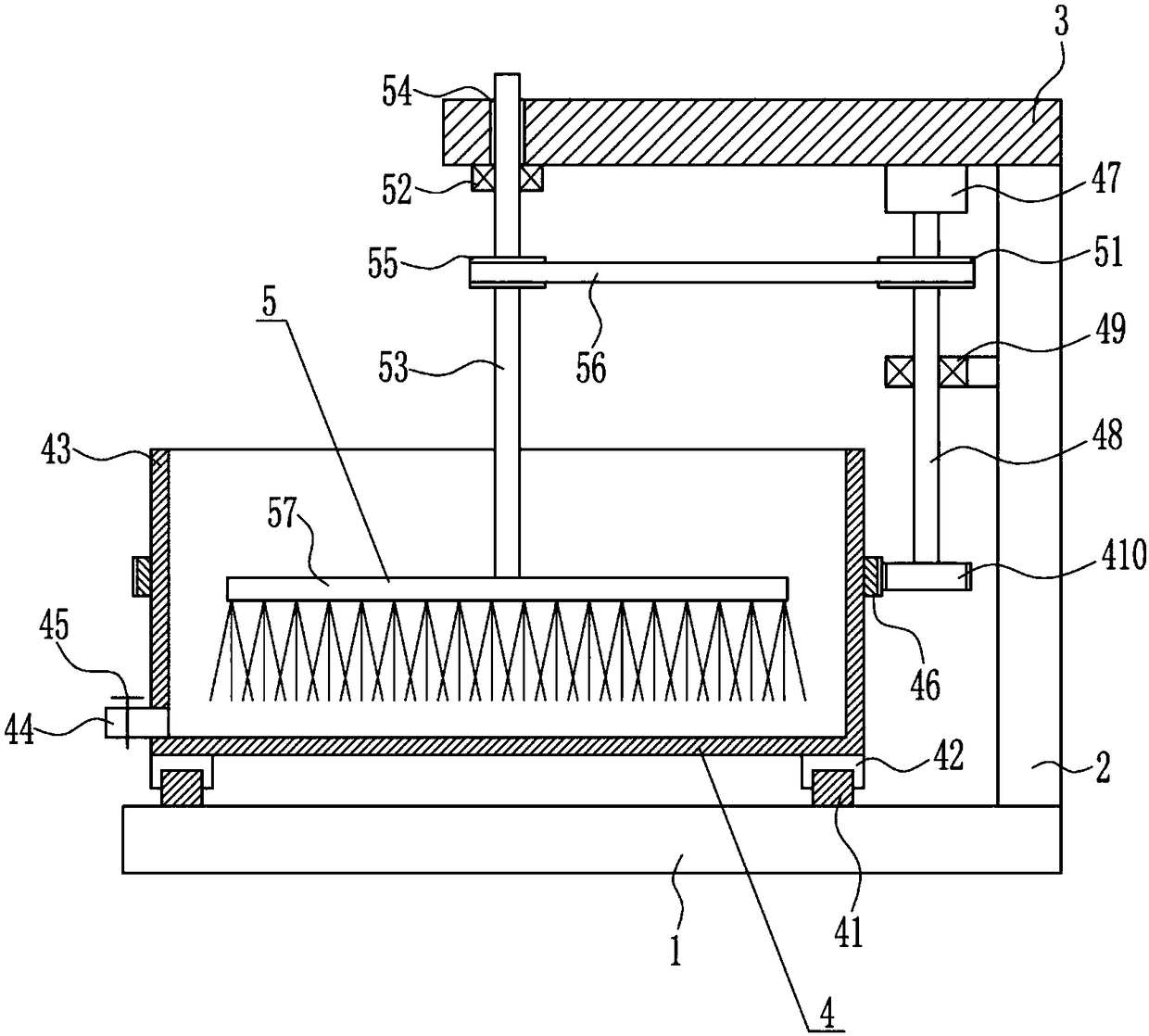

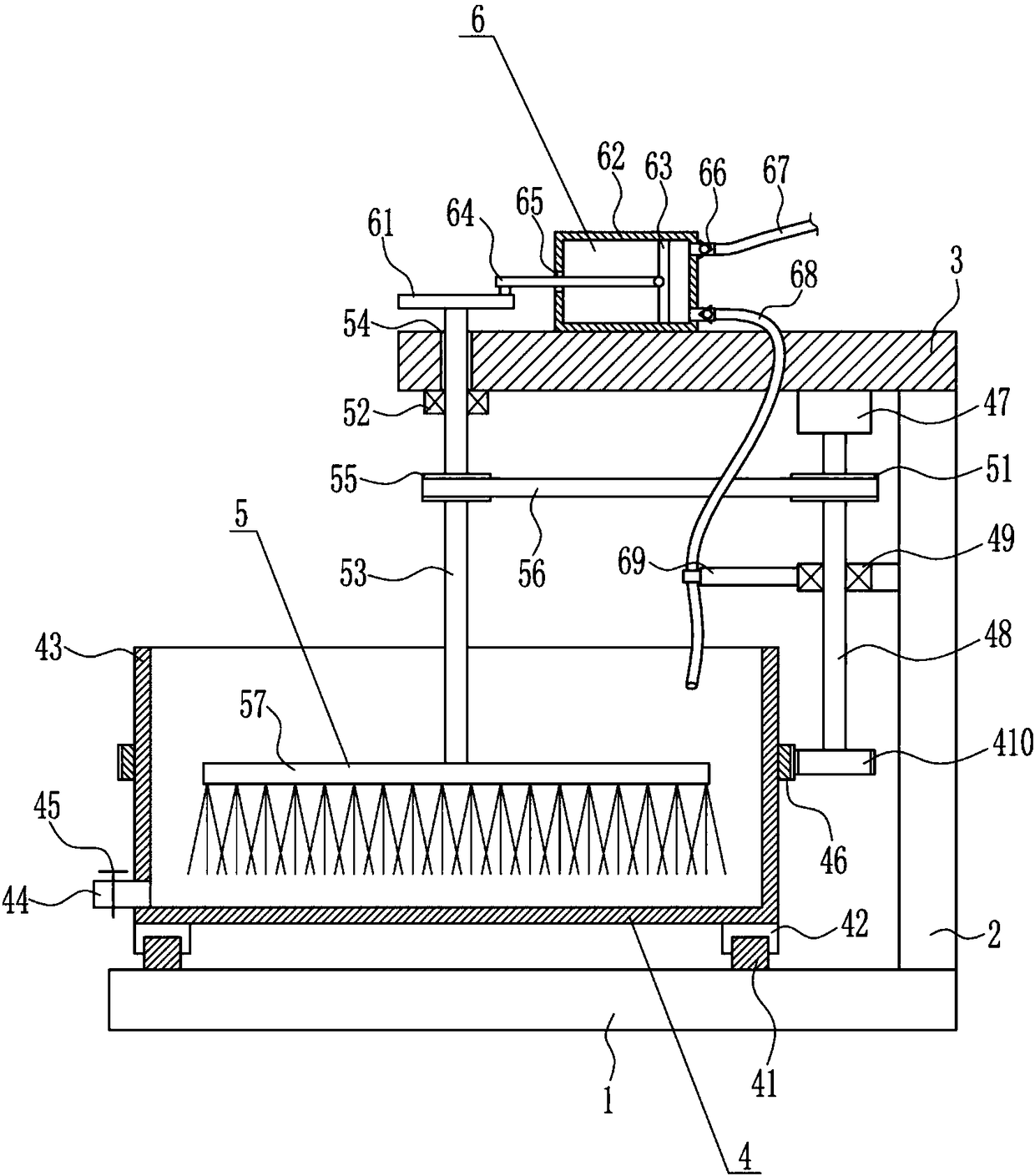

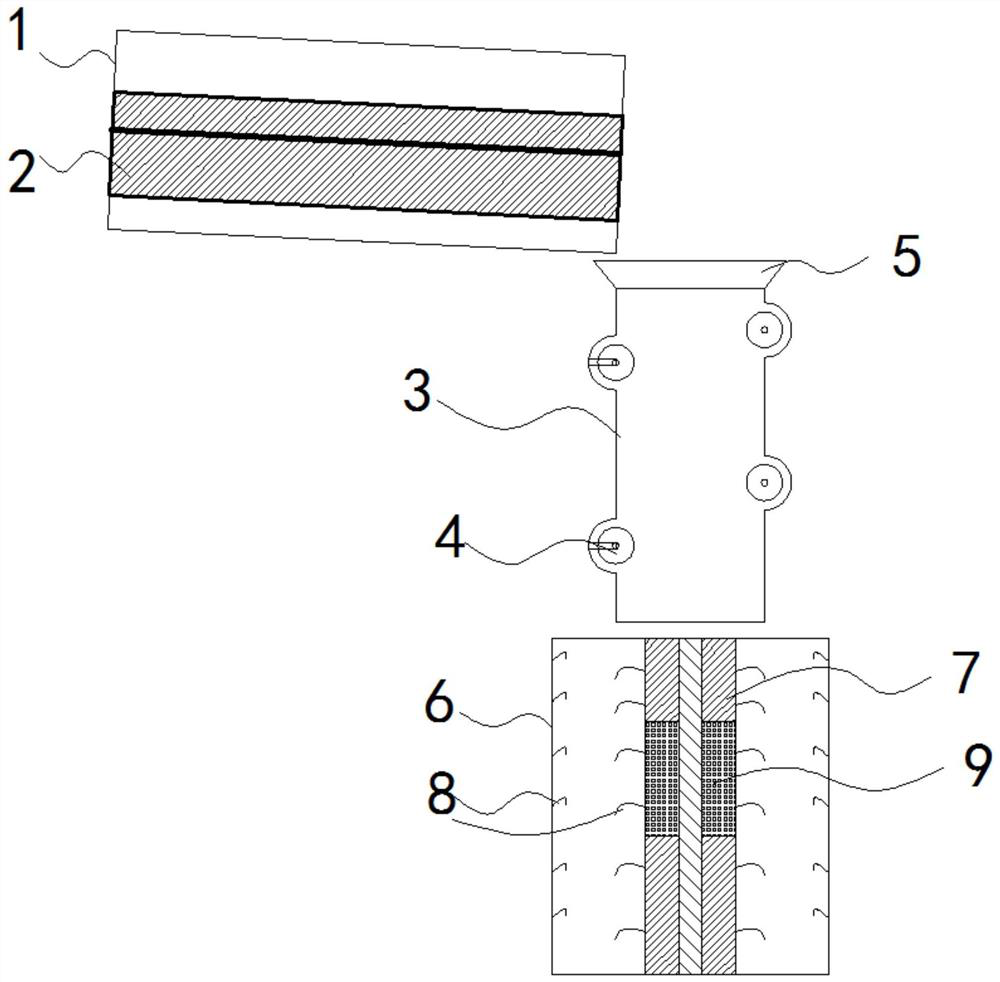

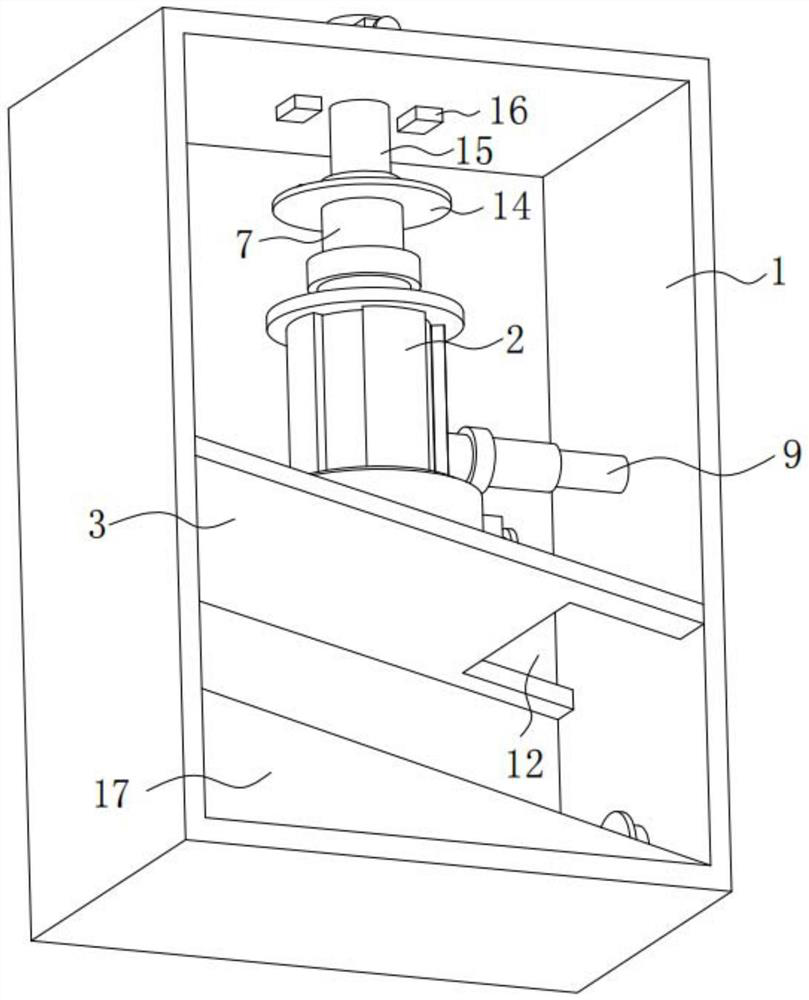

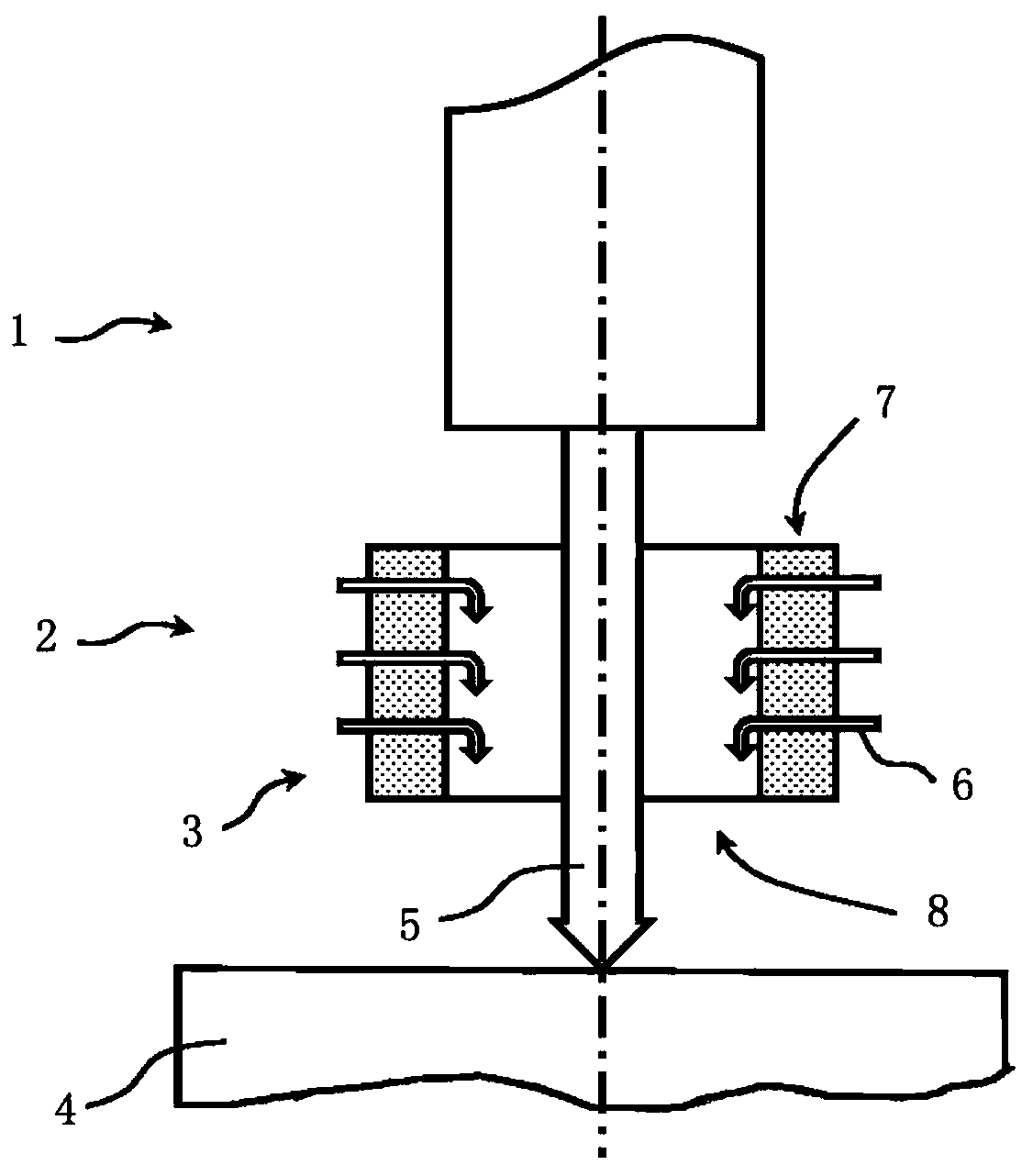

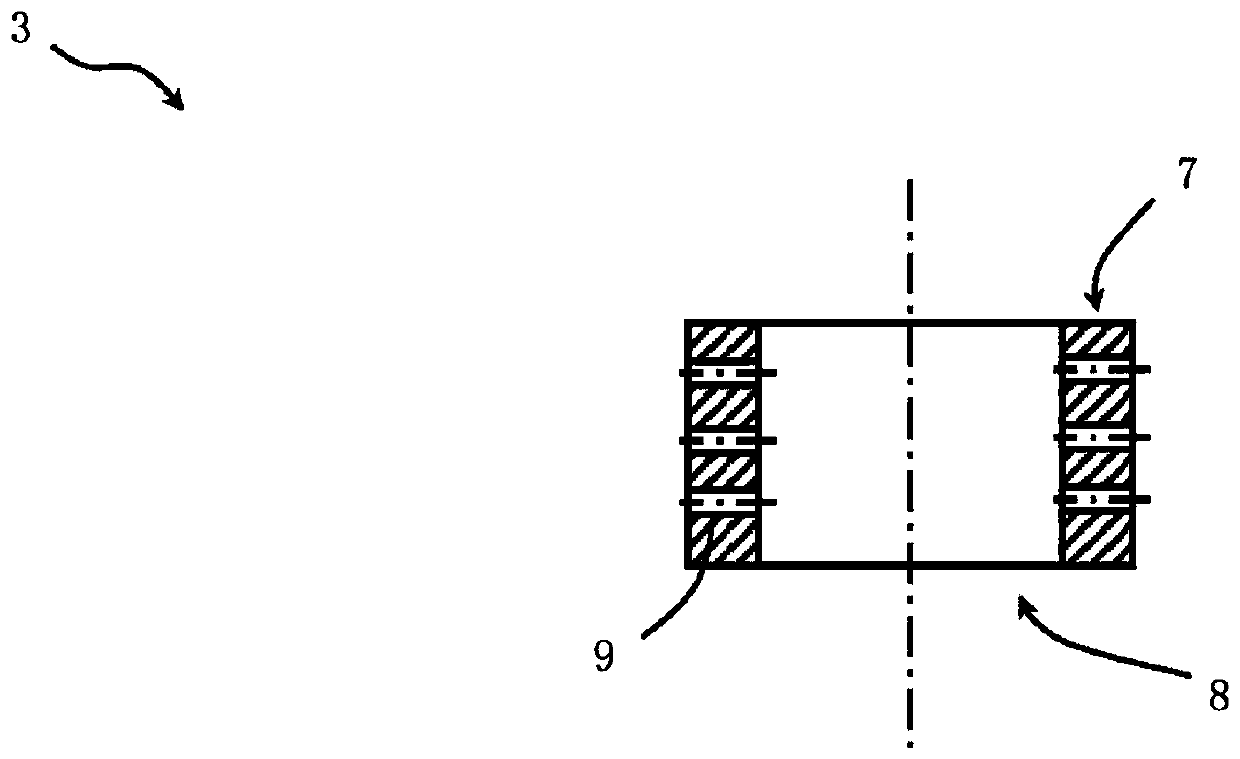

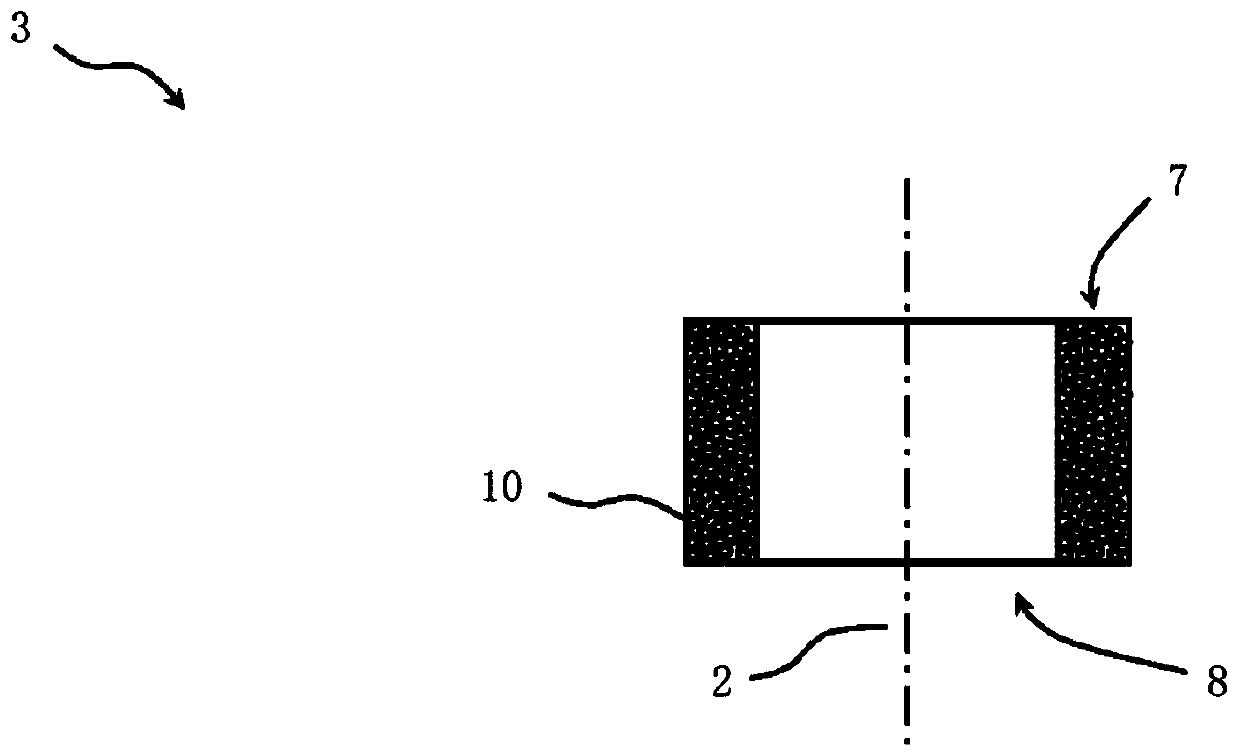

Cleaning device for industrial machine tool worktable

ActiveCN108381284AEasy to cleanCleanerMaintainance and safety accessoriesElectric machineryEngineering

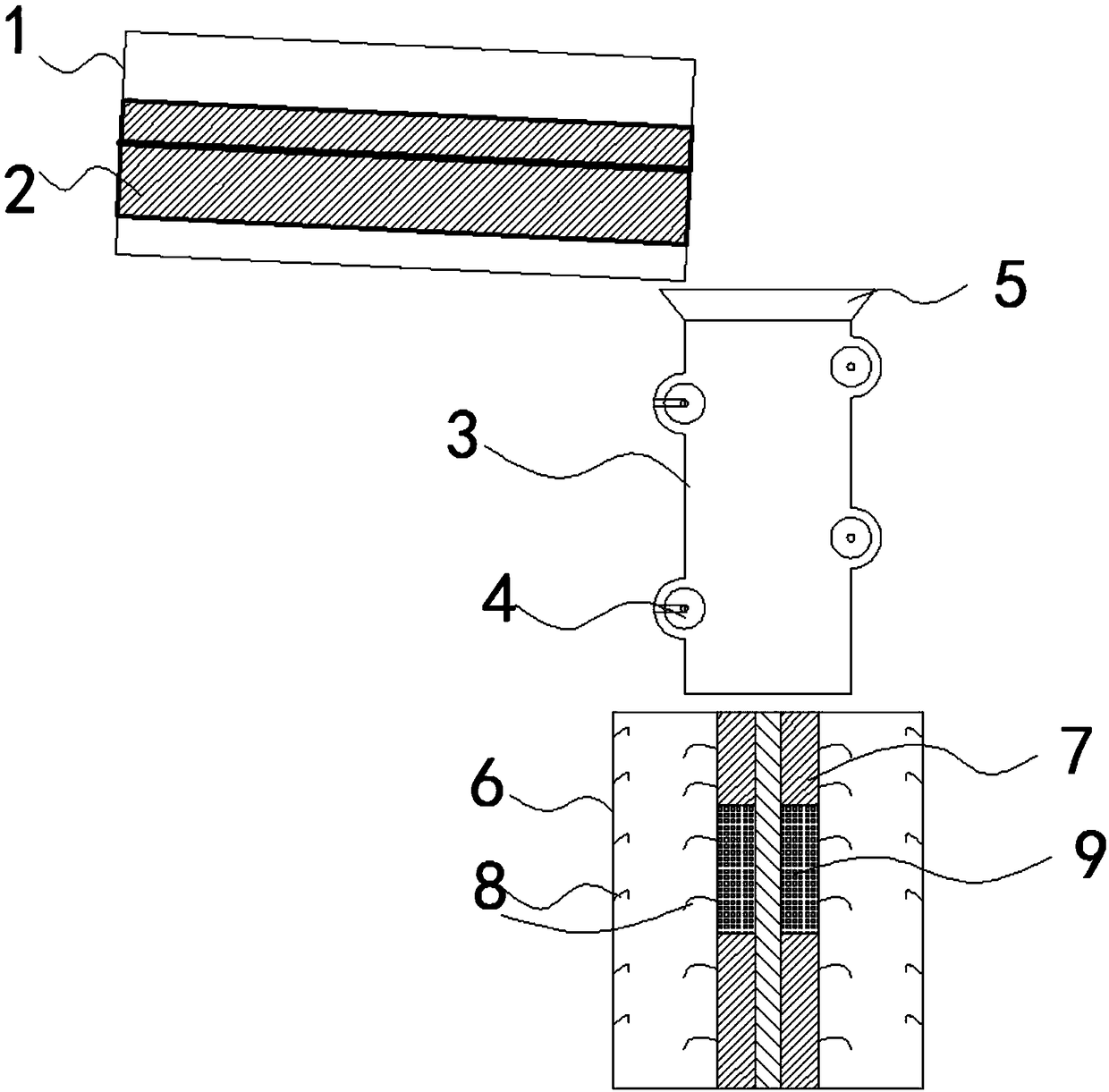

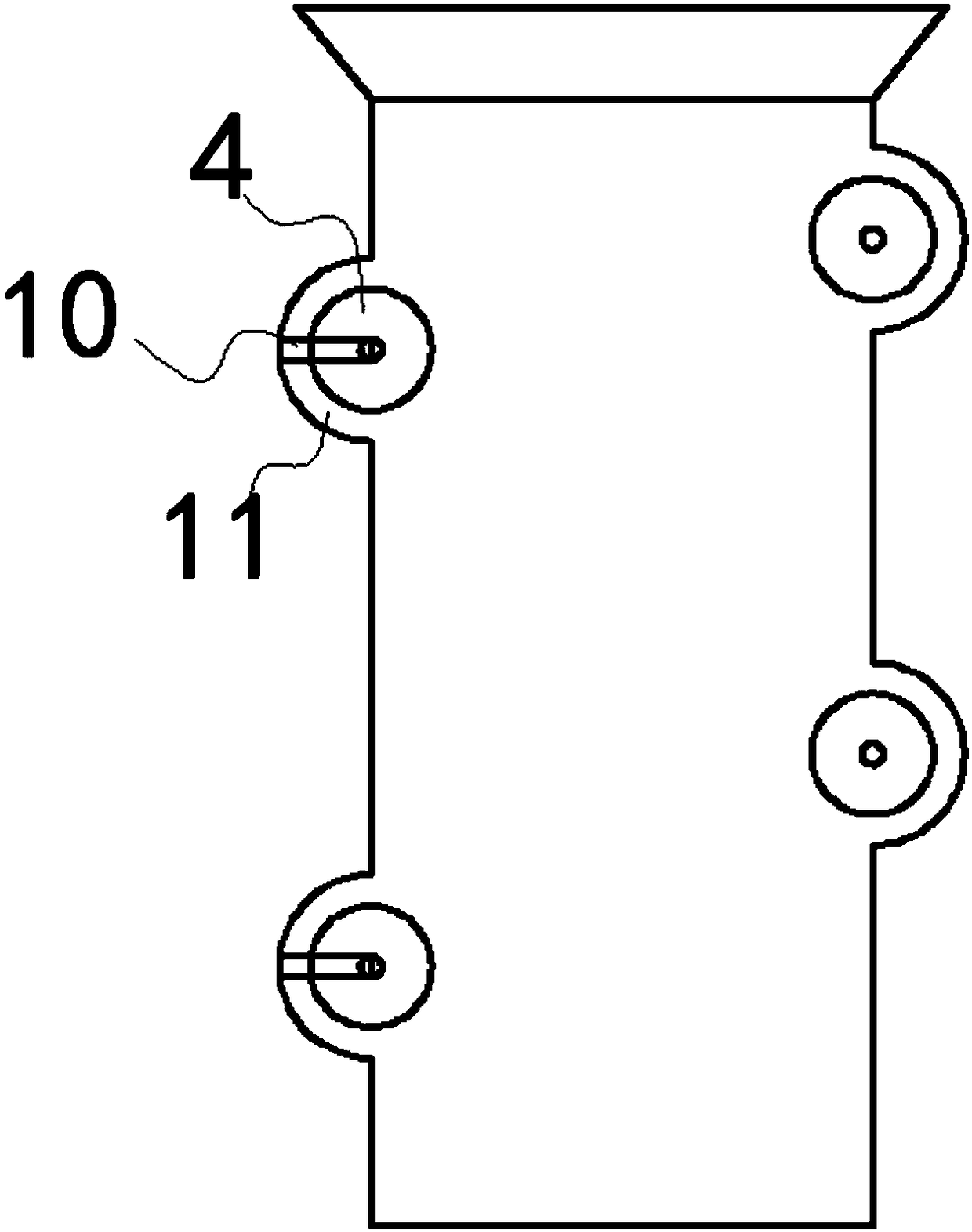

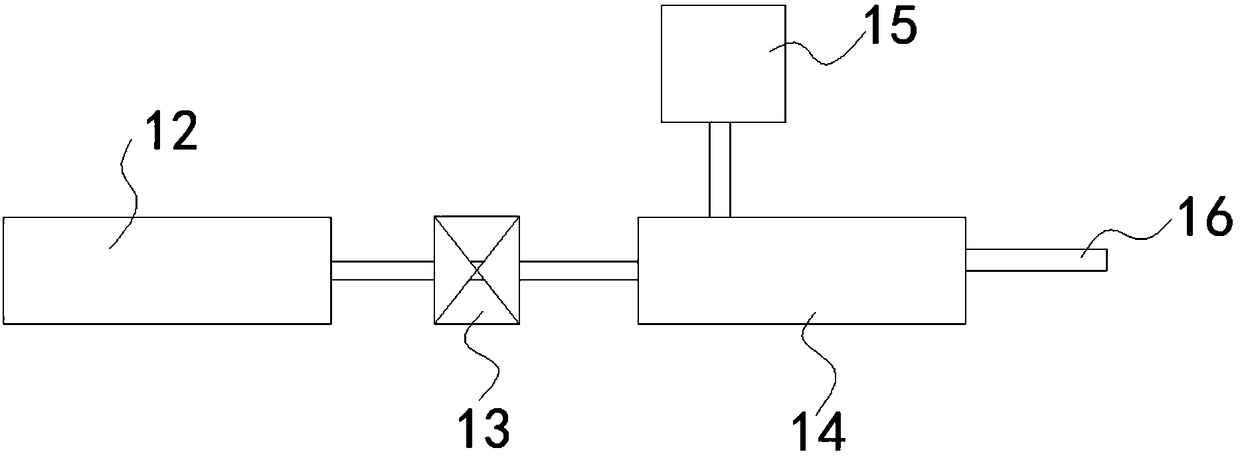

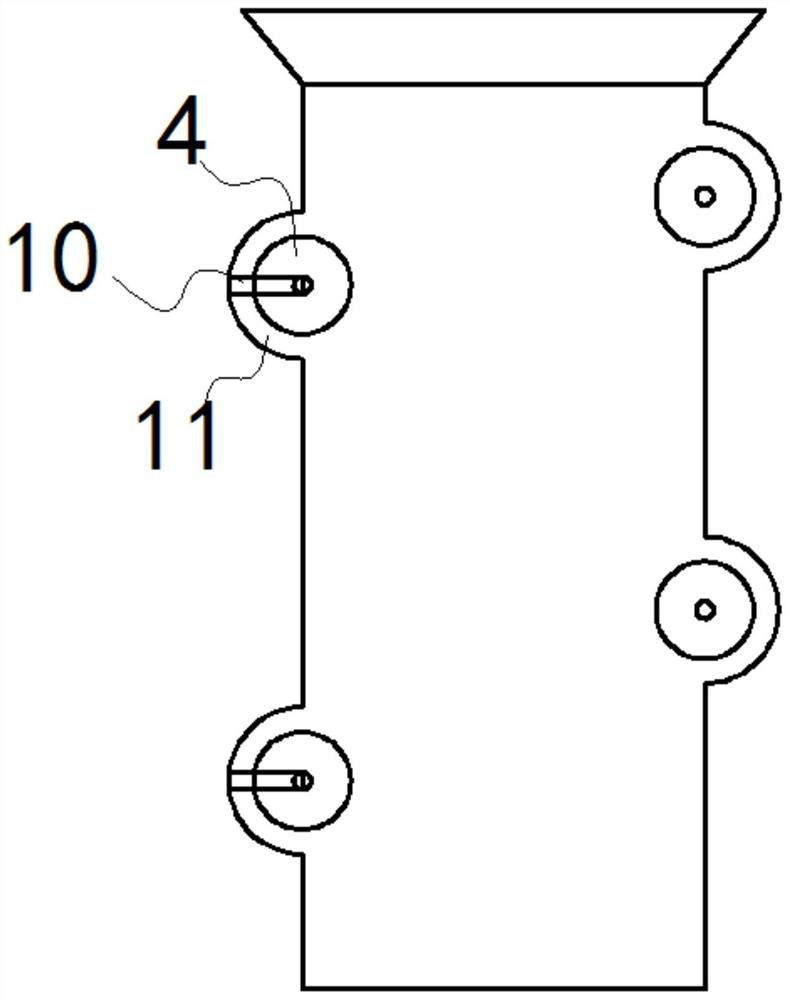

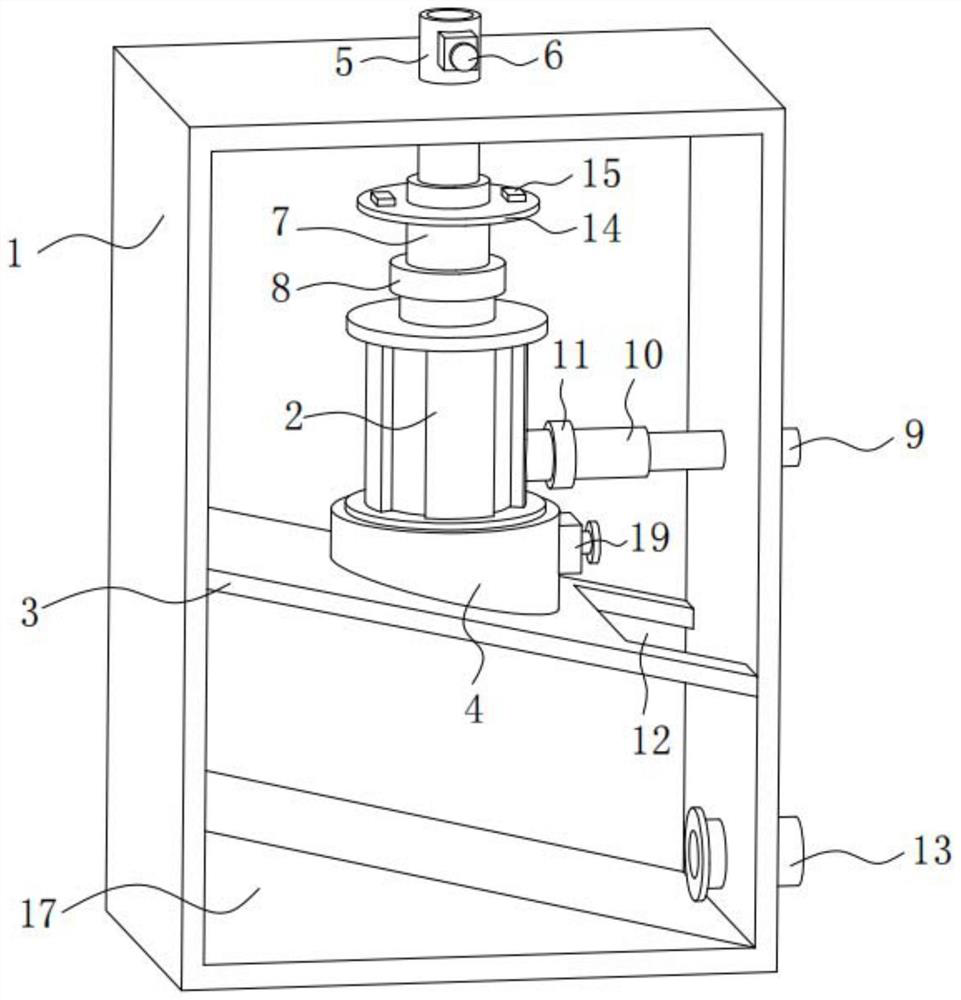

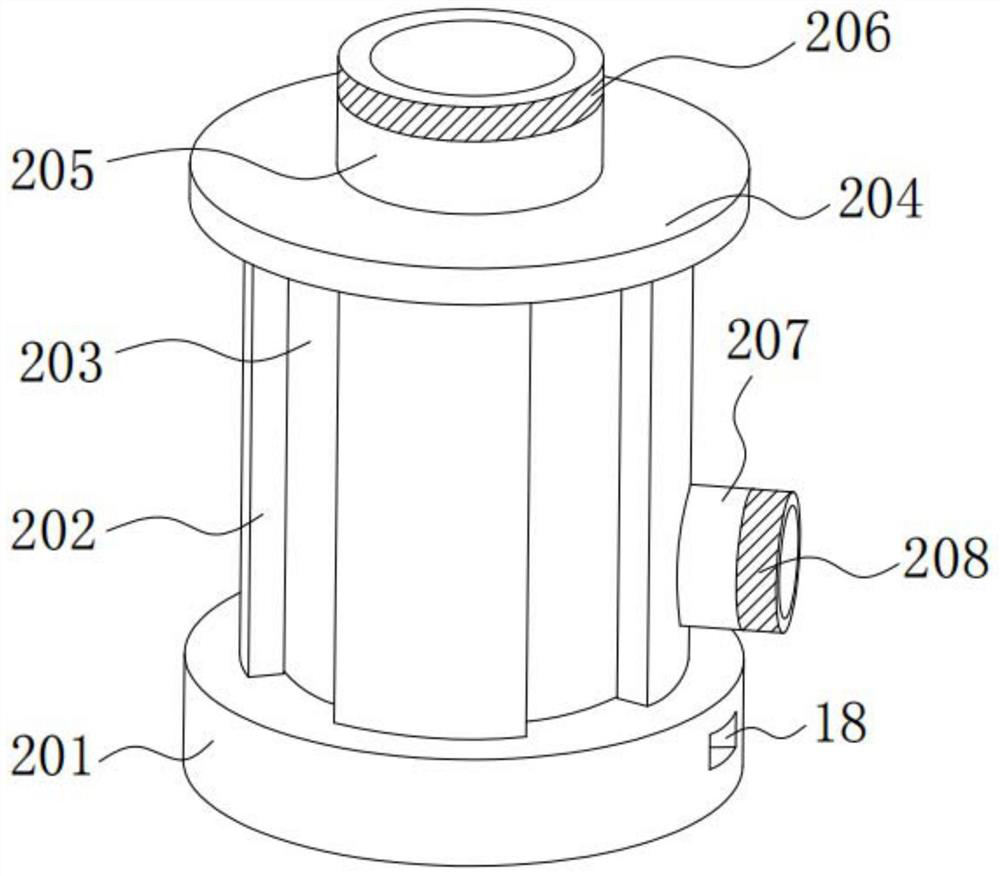

The invention provides a cleaning device for an industrial machine tool worktable, and relates to the field of machine tool equipment. The cleaning device comprises a connecting base; an antiskid layer is arranged in the connecting base; an antirust layer is arranged on the lower side of the antiskid layer; insulation paint is arranged on the lower side of the antirust film; a first support columnis fixedly mounted on the left side of the top of the connecting base; a second support column is fixedly mounted on the right side of the top of the connecting base; and a motor is fixedly mounted at the top of the first support column. The cleaning device for the industrial machine tool worktable can drive a support turntable to totally overturn the worktable through the motor, so that such impurities as iron chips in a groove can fall into an impurity collecting box, and the worktable is conveniently cleaned; water is sprayed to the worktable for cleaning through a water nozzle, so that the worktable can be cleaned more thoroughly, the iron chips in gaps can be effectively removed, and the cleaning efficiency is improved; and through a rinsing device, the iron chip impurities can be sucked through a permanent magnet, and massive iron chips can be taken out from the groove to prevent blockage of a water outlet pipe.

Owner:爱雷德机床有限公司

Method for preparing lithium carbonate with high-lithium salt lake bittern

InactiveCN105036159AReduce contentHigh purityLithium carbonates/bicarbonatesInorganic saltsLithium chloride

The invention relates to the field of inorganic salt chemical engineering and discloses a method for preparing lithium carbonate with high-lithium salt lake bittern. The method comprises the steps of adding inorganic salt into the salt lake bittern for removing impurities, extracting lithium chloride, and then adding addition agents, complexing agents and precipitating agents into a lithium chloride solution for preparing the lithium carbonate. By means of the added complexing agents, micro calcium and magnesium ions remaining in the bittern can be effectively removed, and the content of the calcium and magnesium ions in a lithium carbonate product is reduced; by means of the addition agents, the lithium carbonate purity is effectively raised.

Owner:韦海棉

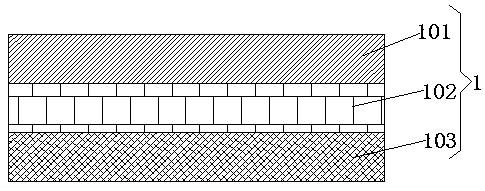

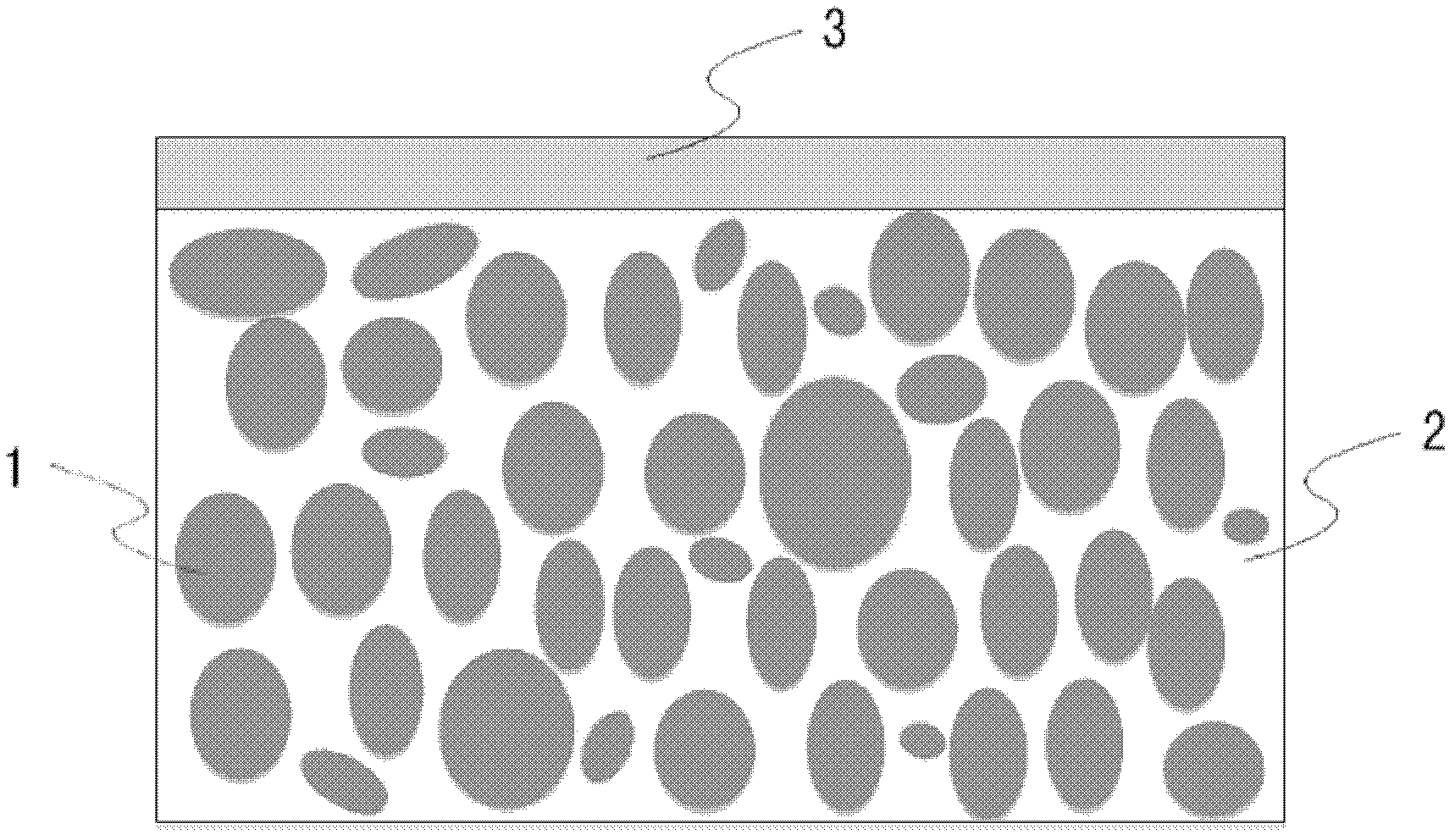

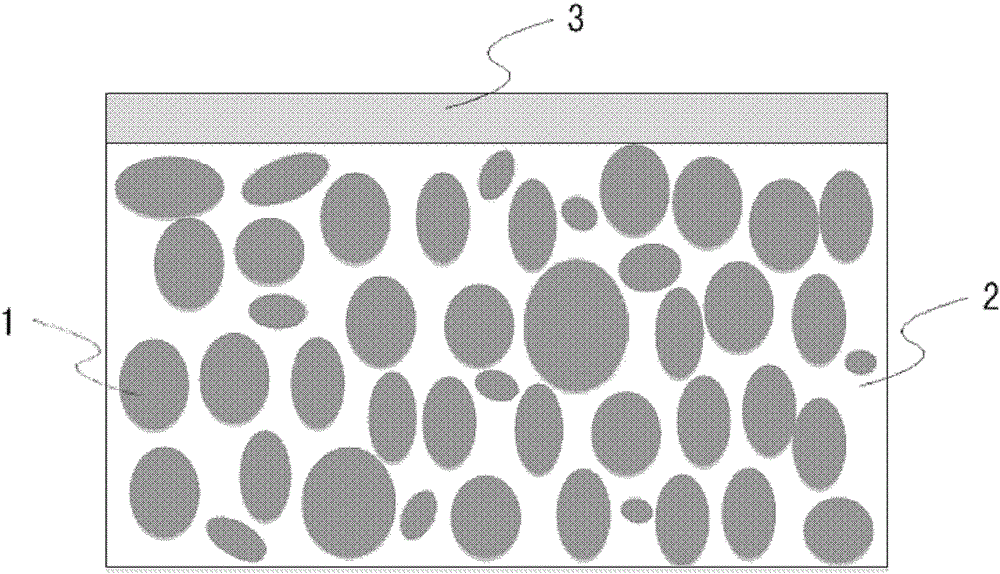

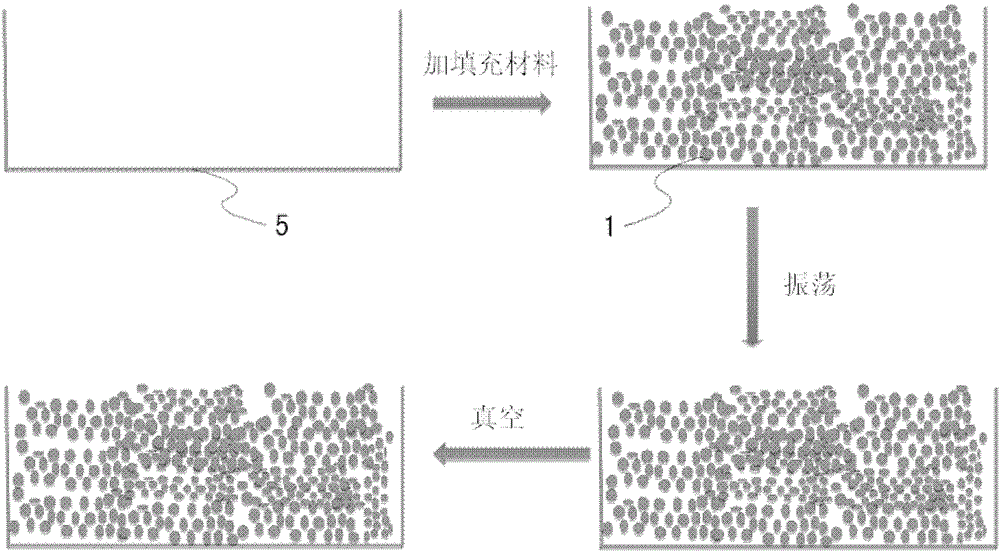

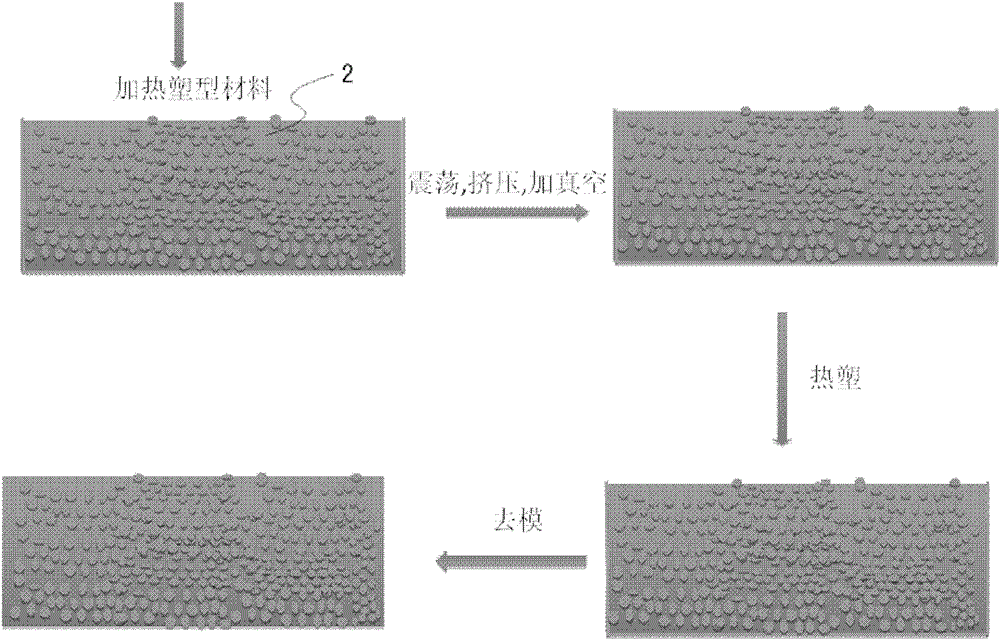

Novel artificial marble

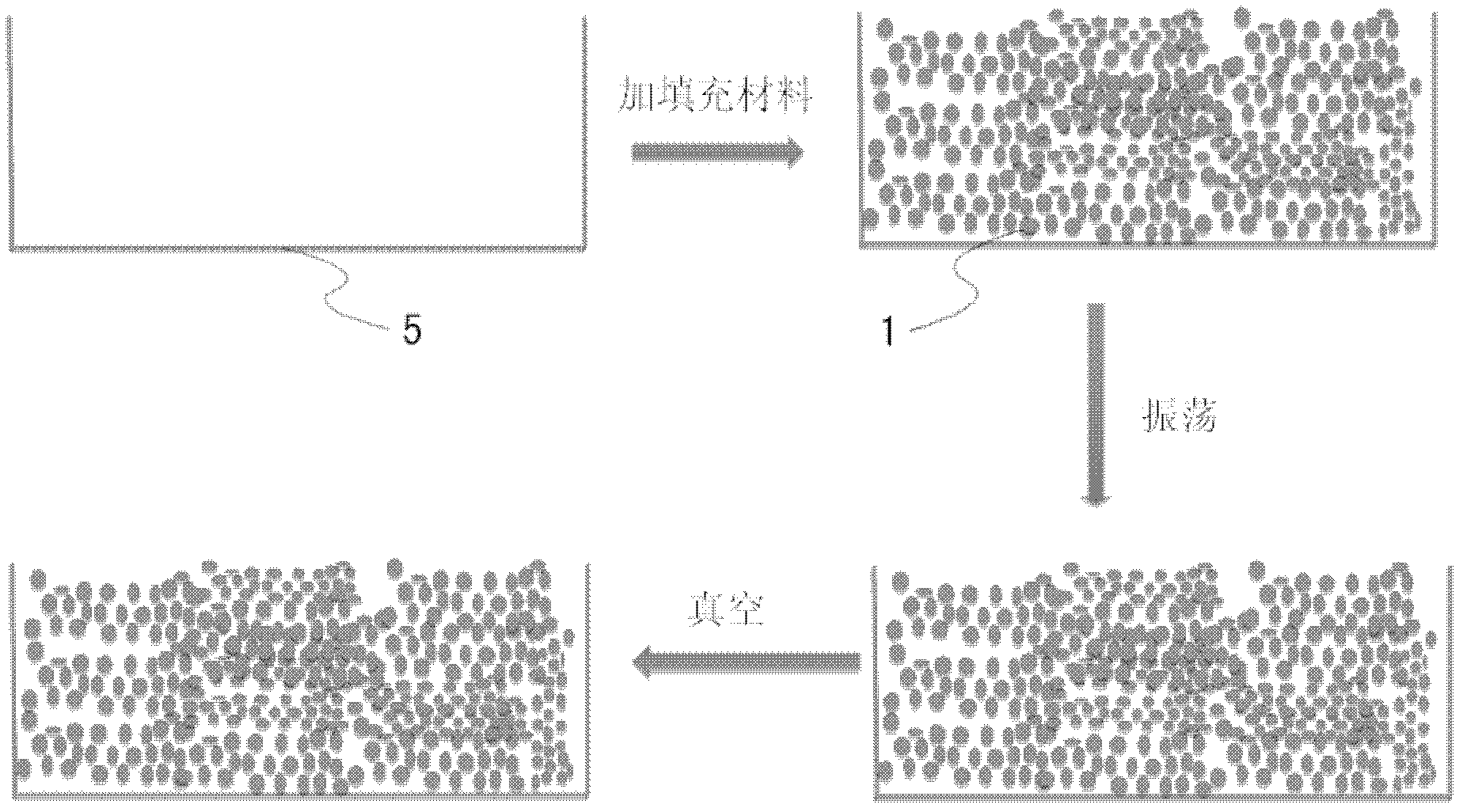

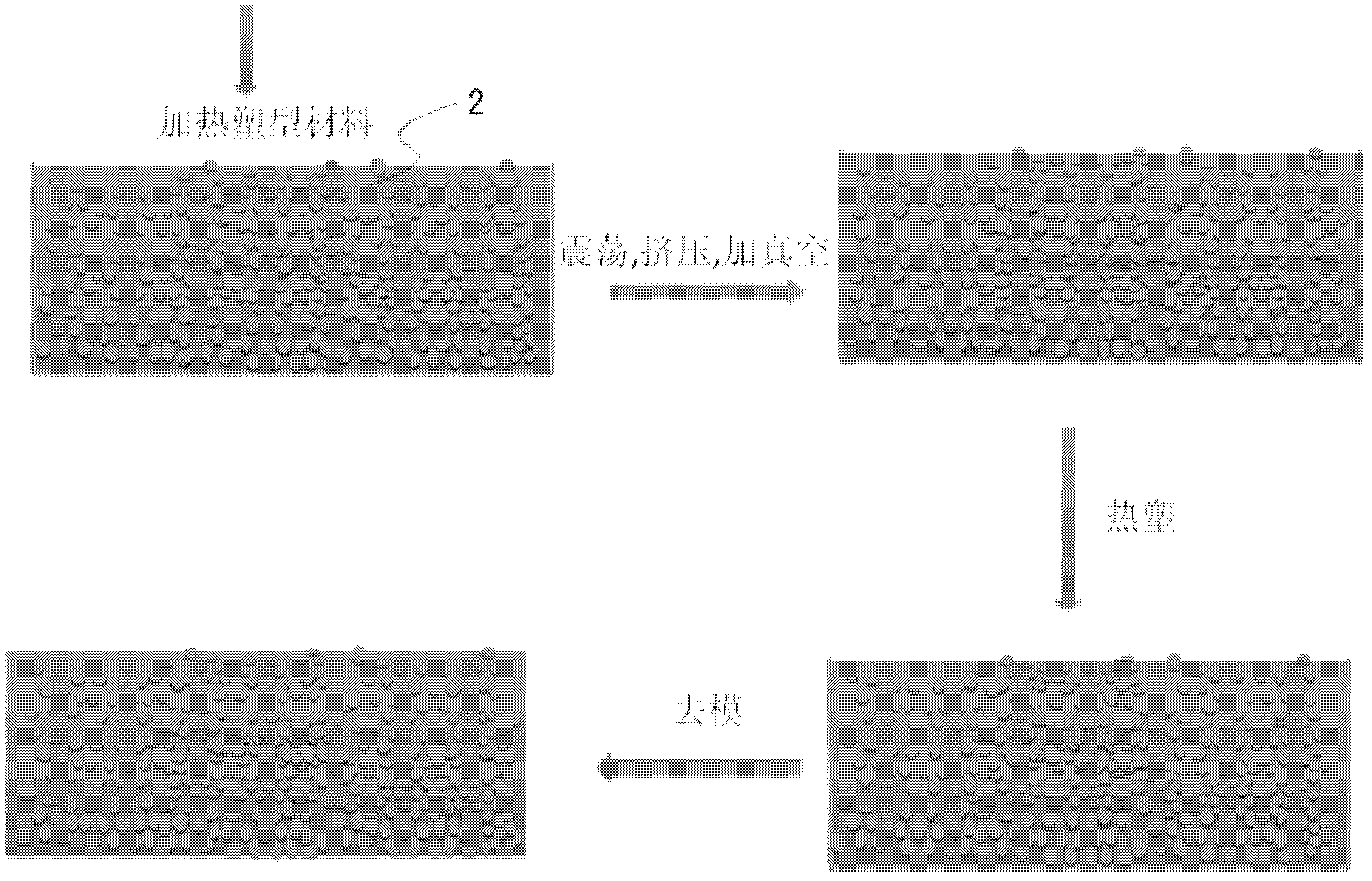

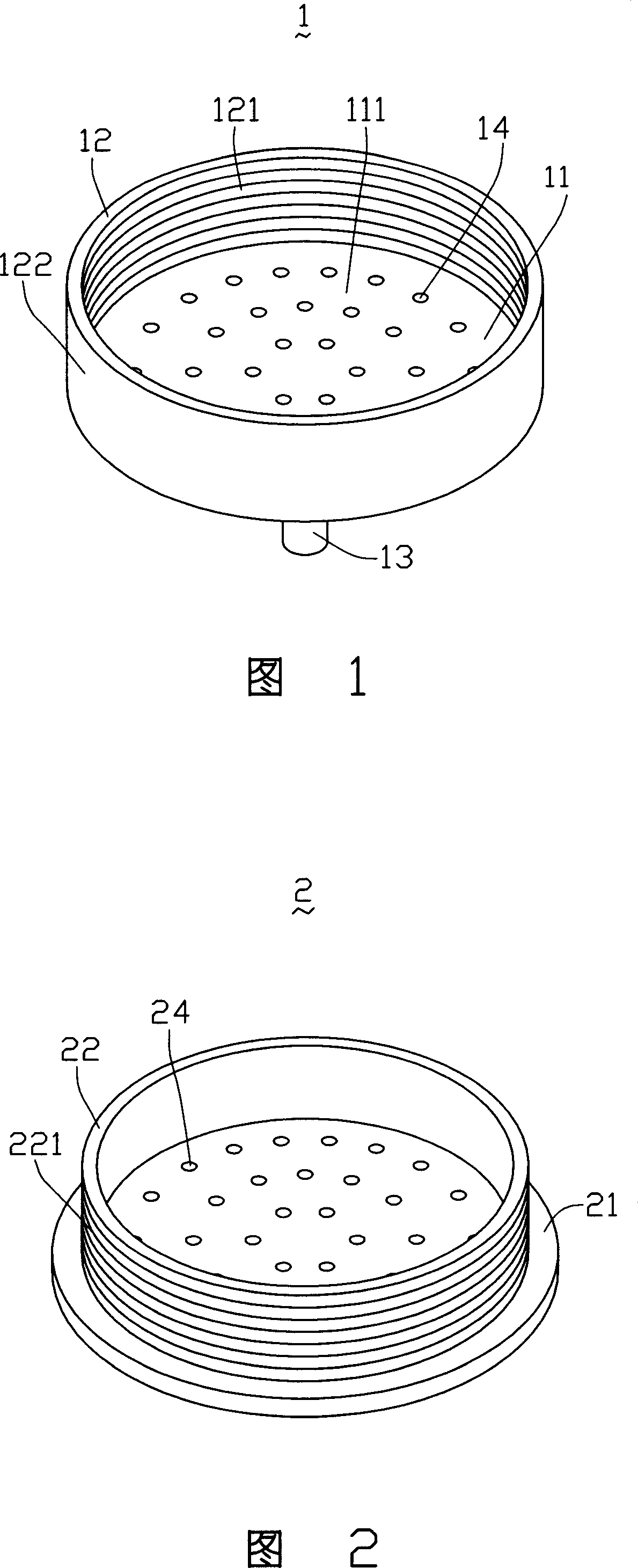

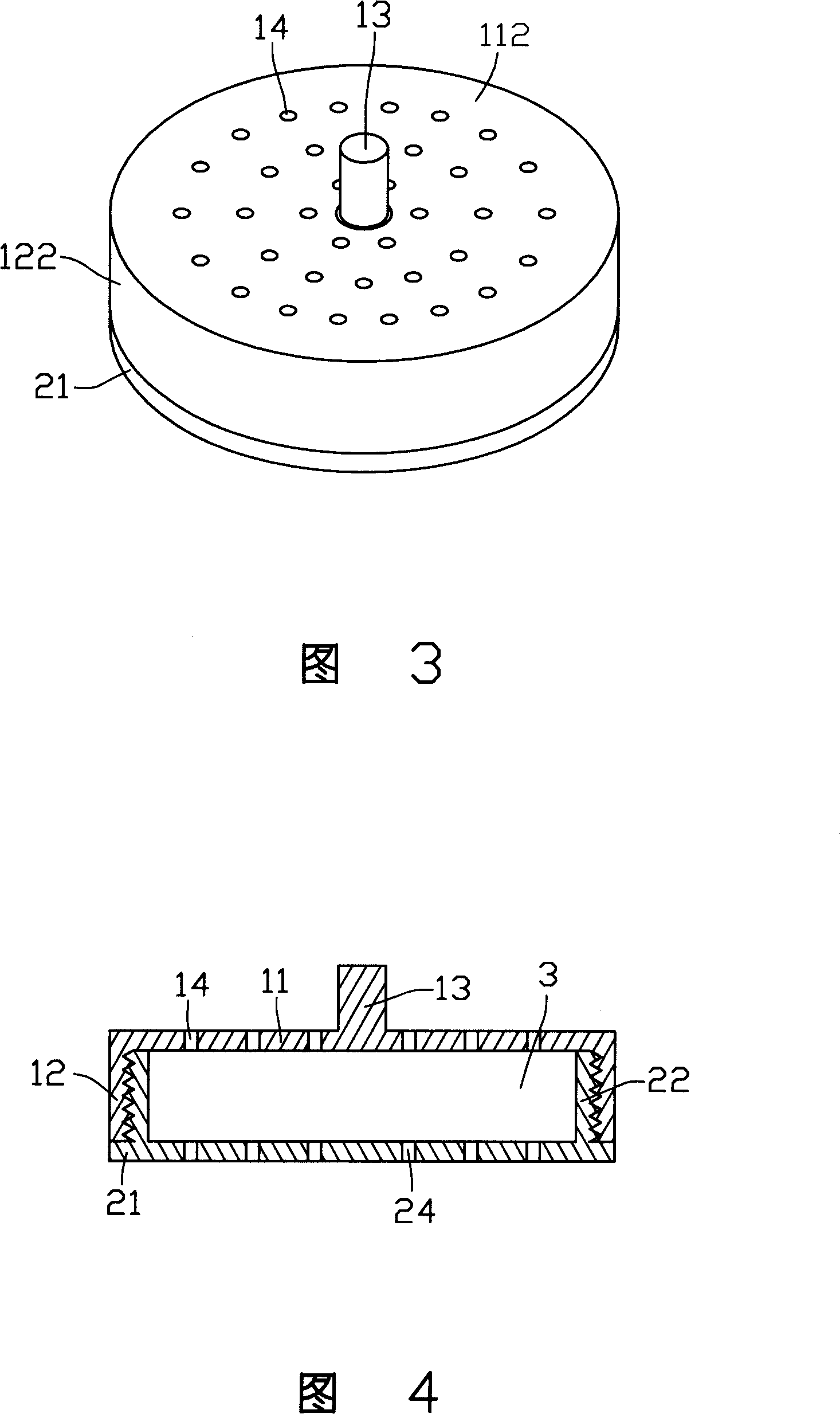

InactiveCN102935738AWith self-cleaning functionWith cleanLayered productsCeramic shaping apparatusDecompositionFilling materials

The invention provides a novel artificial marble and manufacturing method thereof. The novel artificial marble comprises a body layer composed of a filling material and a resin adhesive material, a coating layer containing titanium dioxide or a mixed coating comprising titanium dioxide. The surface of the novel artificial marble has a titanium dioxide coating film or a coating containing titanium dioxide or the mixed coating comprising titanium dioxide, so that the artificial marble has a self-cleaning function, and can greatly reduce cost for maintaining clean when the artificial marble is used as a building material. Due to the excellent ultraviolet absorption function of titanium dioxide, decomposition of the component materials of the artificial marble can be effectively prevented; mechanical performance of the artificial marble can be maintained; and fractures / cracks can be prevented from appearance. The particles or powder of the main raw materials of the artificial marble are inorganic waste materials of buildings and livings and even waste materials of the artificial marble, thereby reducing cost, decreasing resource waste and protecting the environment.

Owner:张磊

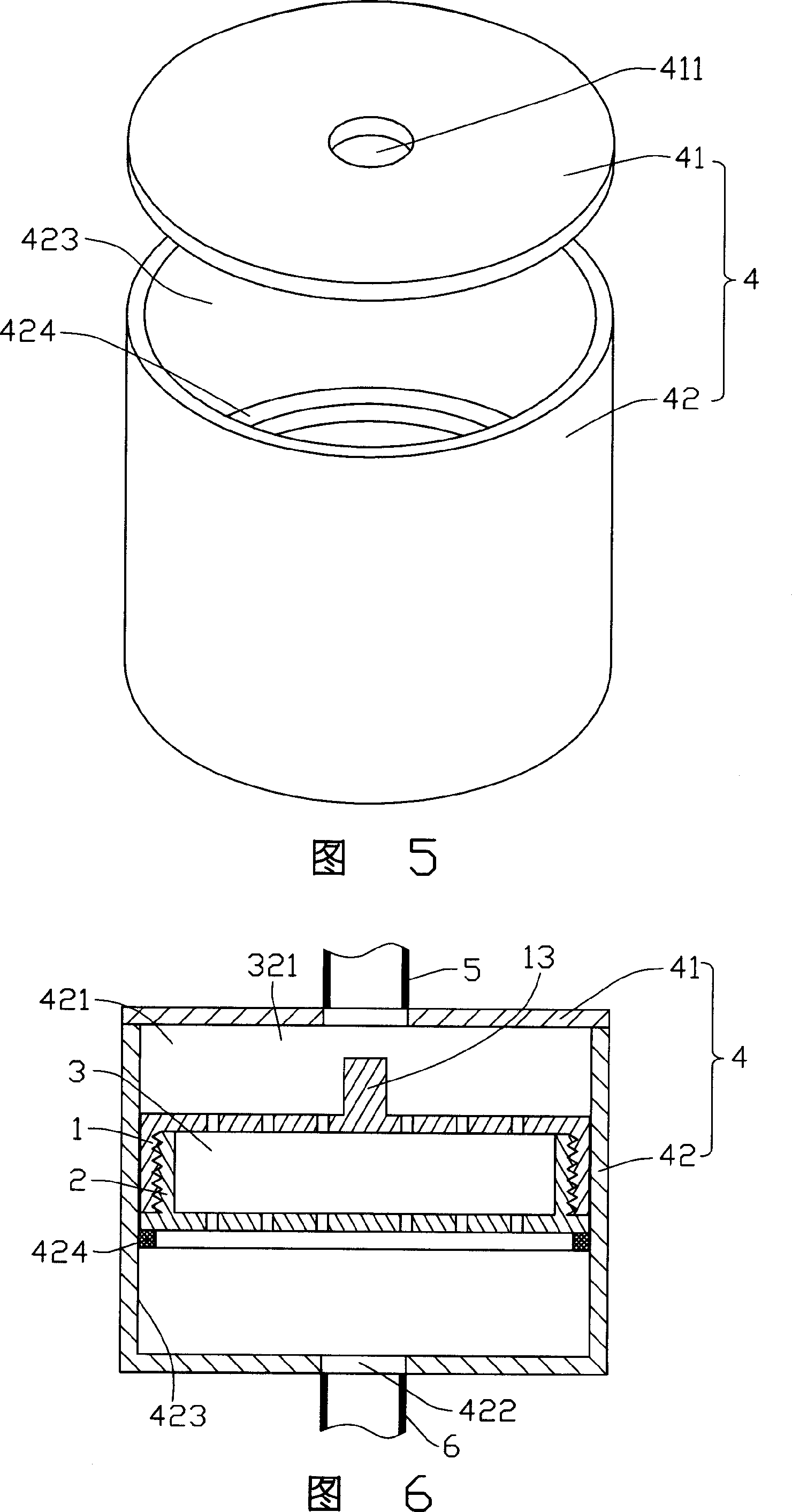

Washing fixture and washing method

InactiveCN101024225AHigh speedEffectively wash offWork holdersFlexible article cleaningEngineeringMechanical engineering

The invention relates to a cleaning cassette. It includes one upper cover set many cleaning holes and one lower plate set many lower cleaning holes. They are matched with each other to form one cleaning cavity. The cleaning method is that using the cleaning cassette to clean the work piece. The invention can use running water to clean the work piece, which can obviously increase cleaning speed, gain better cleaning effect.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

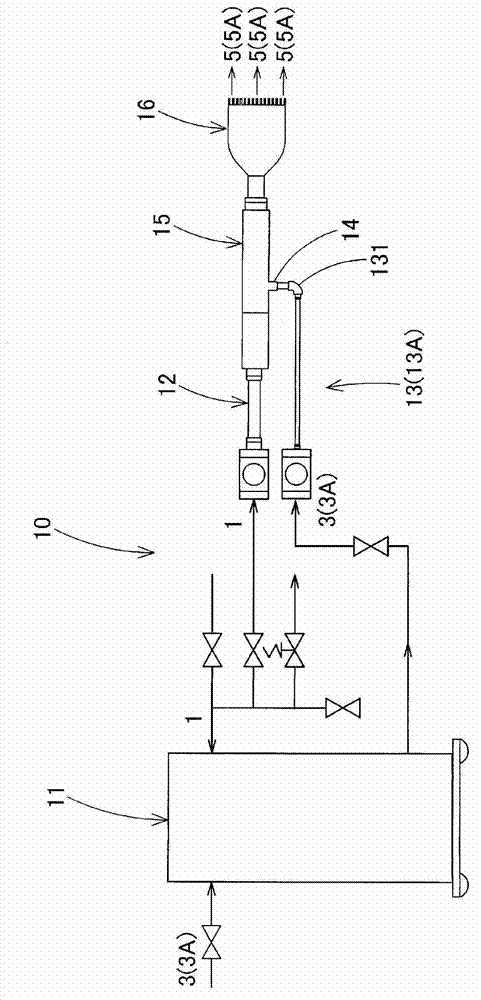

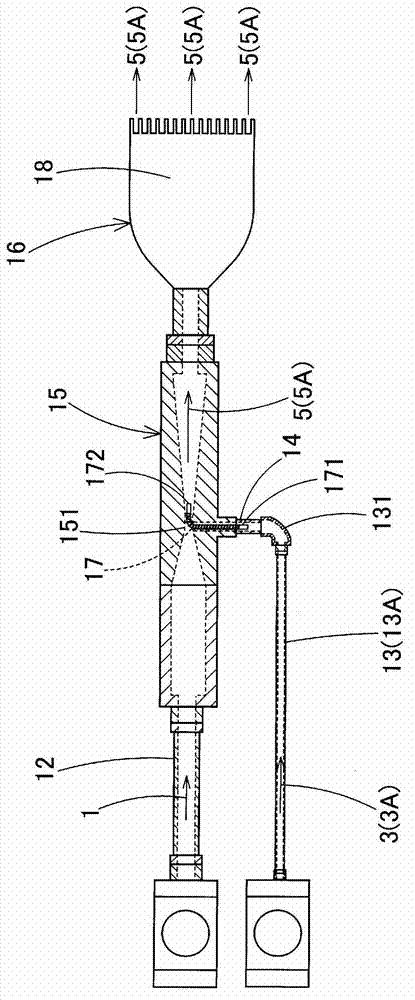

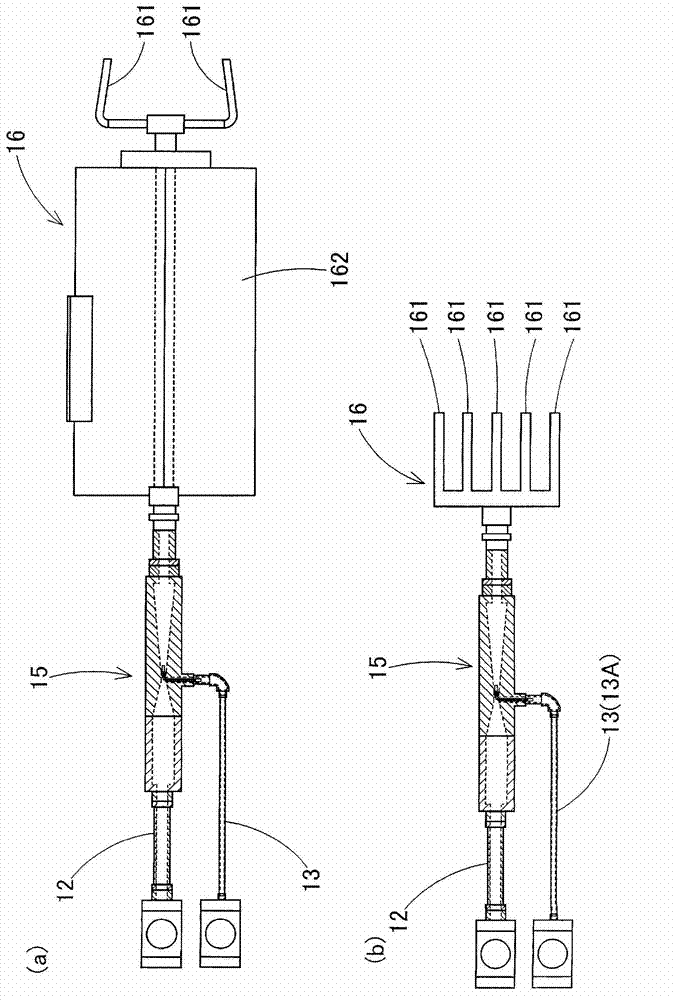

Fluid mixture spray device

InactiveCN102822019AEffectively wash offEasy to sprayMovable spraying apparatusSpray nozzlesCoated surfaceWash water

Owner:I TAC GIKEN

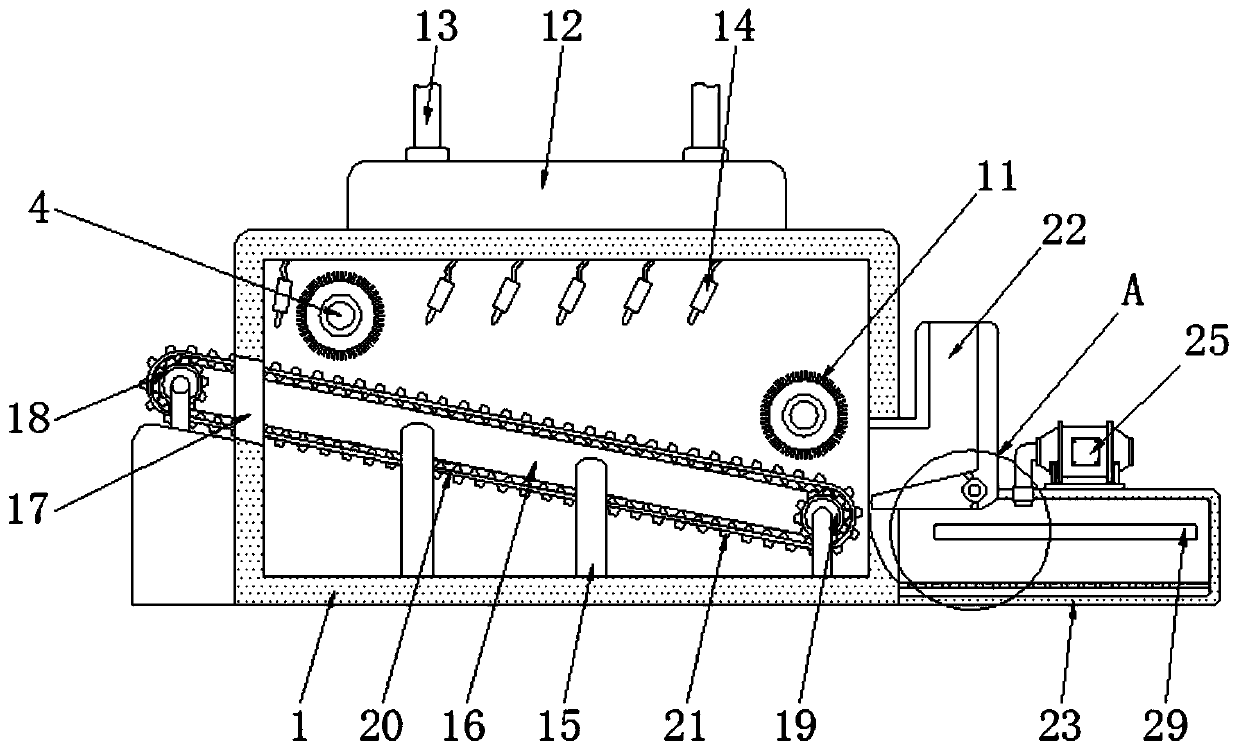

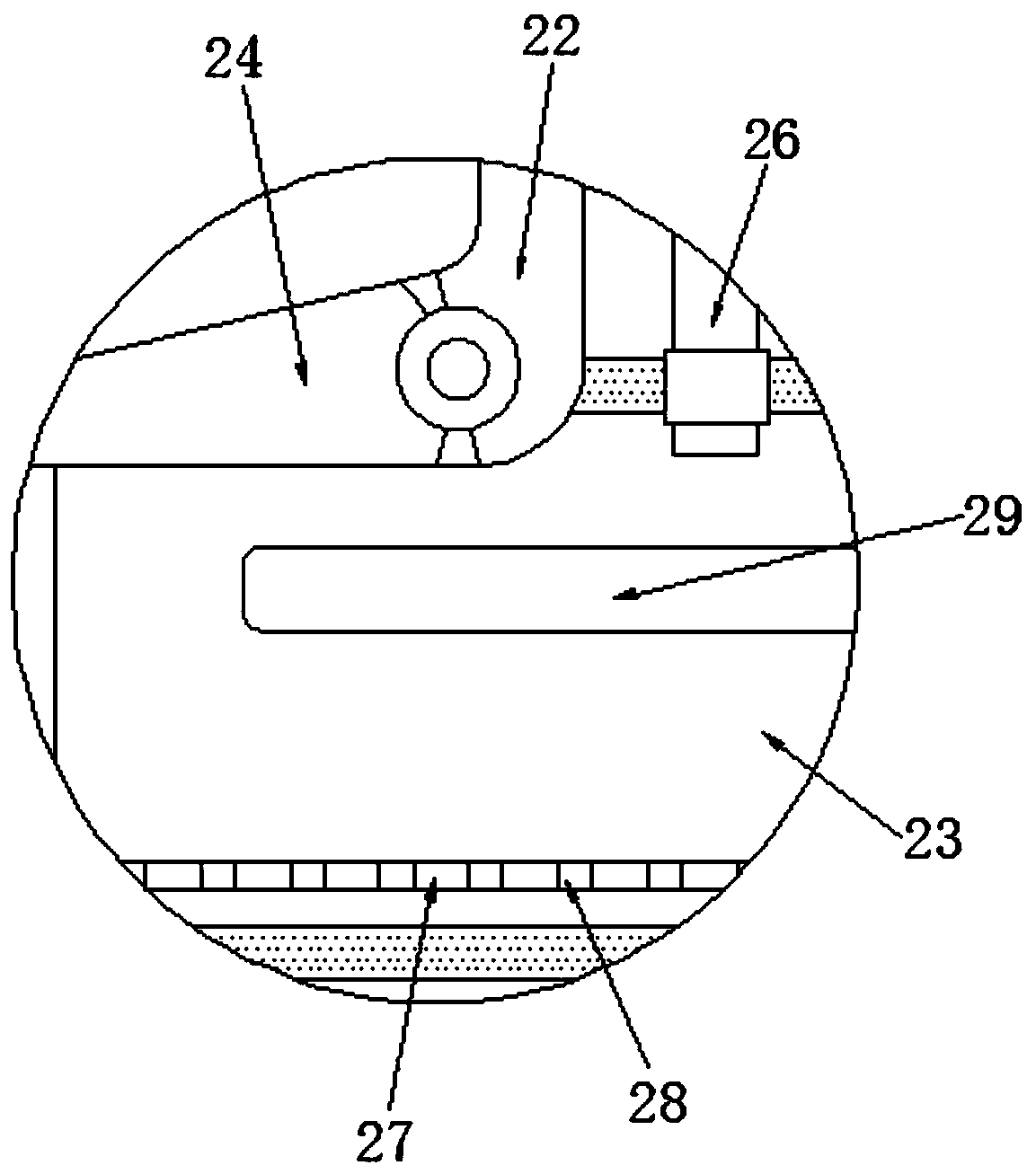

Cleaning device used for printing industry

InactiveCN110882951AQuick washWash thoroughlyDrying gas arrangementsCleaning using toolsReciprocating motionElectric machinery

The invention discloses a cleaning device used for the printing industry. The cleaning device comprises a box body, wherein a drive motor and a fixed frame are fixedly connected on the surface of thebox body from top to bottom separately; the two sides of the inner cavity of the box body are rotatably connected with rotary rollers; ends of the two rotary rollers penetrate through the inner cavityof the box body and extend to the surface of the box body. The invention relates to the technical field of the printing industry. According to the cleaning device used for the printing industry disclosed by the invention, a printing roller slides into the box body along with the inclined surface of a feeding pipeline, drops onto an elastic separating block, and is driven to move leftwards under driving of a transmission caterpillar band while the drive motor is started; the drive motor drives a rotary rod to move back and forth through a connecting sleeve, and the rotary rollers separately drive two cleaning brushes to rotate in reverse directions to clean the surface of a printing roller, so that dirt on the surface of the printing roller can be effectively cleaned; and moreover, more printing rollers can be quickly cleaned through transmission of the transmission caterpillar band, so that cleaning is complete, and cleaning efficiency is high.

Owner:安徽省潜山县志发机电配件有限公司

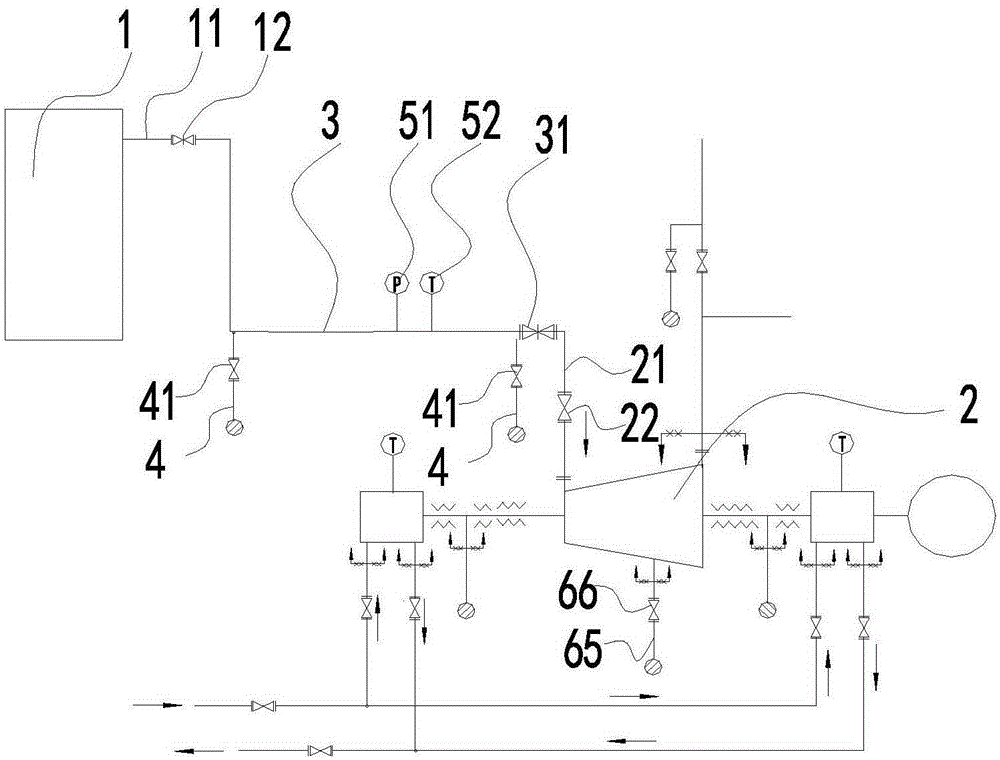

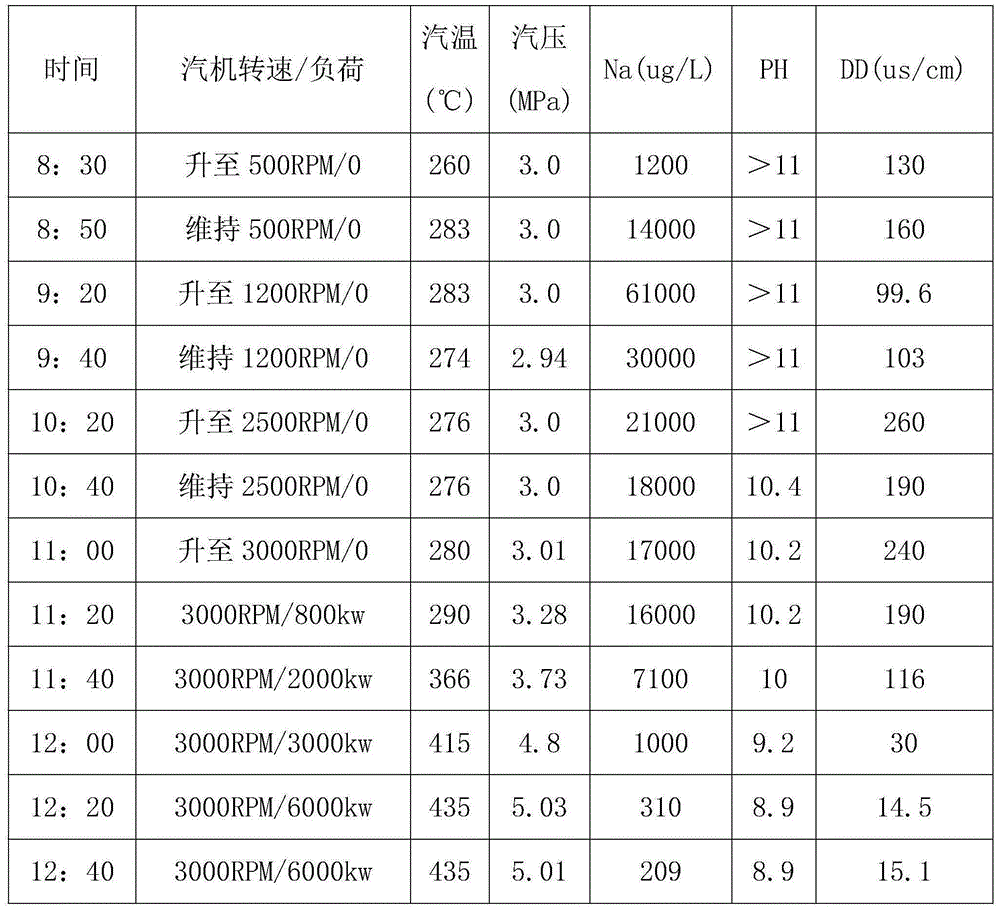

Steam turbine circulation part cleaning system and cleaning method

InactiveCN105201567AImprove securityReduce the temperatureMachines/enginesEngine componentsImpellerSteam pressure

The invention discloses a steam turbine circulation part cleaning system and cleaning method. The steam turbine circulation part cleaning system comprises a steam turbine and a steam generator, wherein a generator steam outlet pipe is arranged on the steam generator; a generator steam outlet valve is arranged on the generator steam outlet pipe; a steam turbine steam inlet pipe is arranged on the steam turbine; a steam turbine steam inlet valve is arranged on the steam turbine steam inlet pipe; the generator steam outlet pipe and the steam turbine steam inlet pipe are connected through a steam main pipe; a main valve, an outlet steam pressure gauge and an outlet steam temperature gauge are arranged on the steam main pipe; both the outlet steam pressure gauge and the outlet steam temperature gauge are located at the upstream part of the main valve; a plurality of drain pipes are arranged on the steam main pipe, and drain valves are arranged on the drain pipes respectively; during cleaning of a steam turbine circulation part, the main valve is opened when the steam pressure of the steam generator reaches 3.0 MPa and the steam temperature reaches 235 DEG C, steam impulses the steam turbine to start, and flowing steam washes out scales on an impeller, blades, a partition and a spray nozzle group of the steam turbine.

Owner:苏州市江远热电有限责任公司

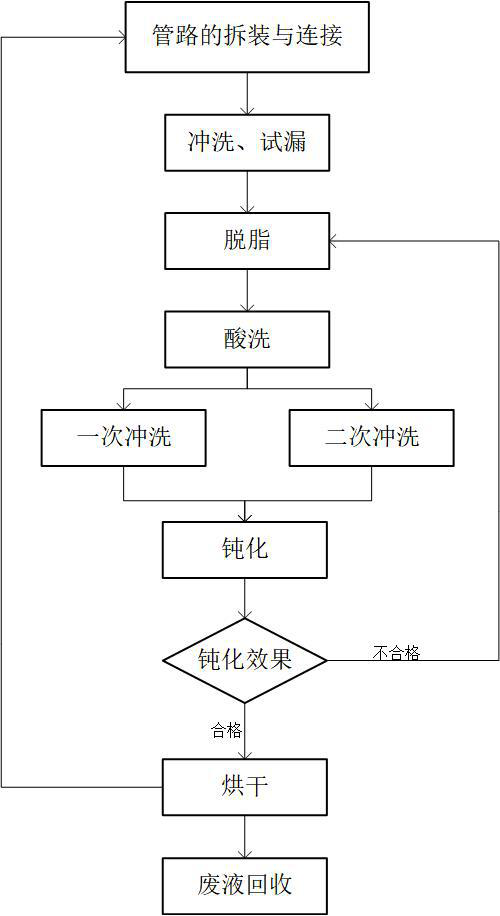

Cleaning process for medium pipeline of continuous casting equipment

InactiveCN114032555ASolve cleaning difficultiesEffectively wash offHollow article cleaningMetallic material coating processesLine tubingProcess engineering

The invention relates to a pipeline cleaning process design which is mainly used for cleaning a medium pipeline of continuous casting equipment in the steel production process. The pipeline cleaning process mainly comprises the procedures of pipeline disassembly, assembly and connection, flushing, leakage testing, degreasing, primary acid pickling, secondary acid pickling, passivation, drying, waste liquid recovery, pipeline reinstallation and the like. According to the process, acid pickling and passivation processes of the medium pipeline are combined, degreasing and dual cleaning are carried out in the acid pickling process, and problems that the medium pipeline in continuous casting equipment is difficult to clean, low in cleaning quality, uneven in cleaning and the like due to many kinds of media, complex media and the like are solved. The cleaning efficiency of an existing process is improved, the cleaning cost is saved to a certain extent, waste liquid is uniformly recycled after cleaning, and the burden of chemical pollution products on environmental protection is relieved.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

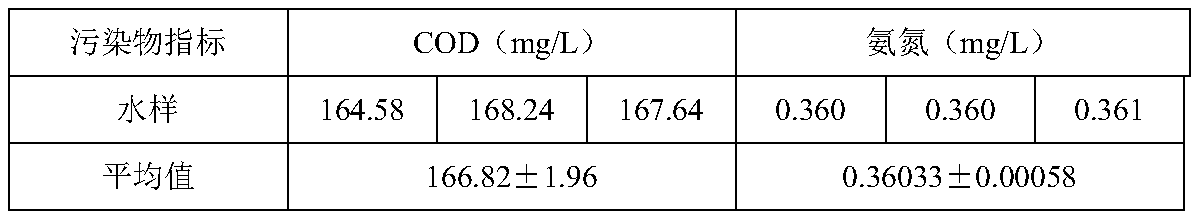

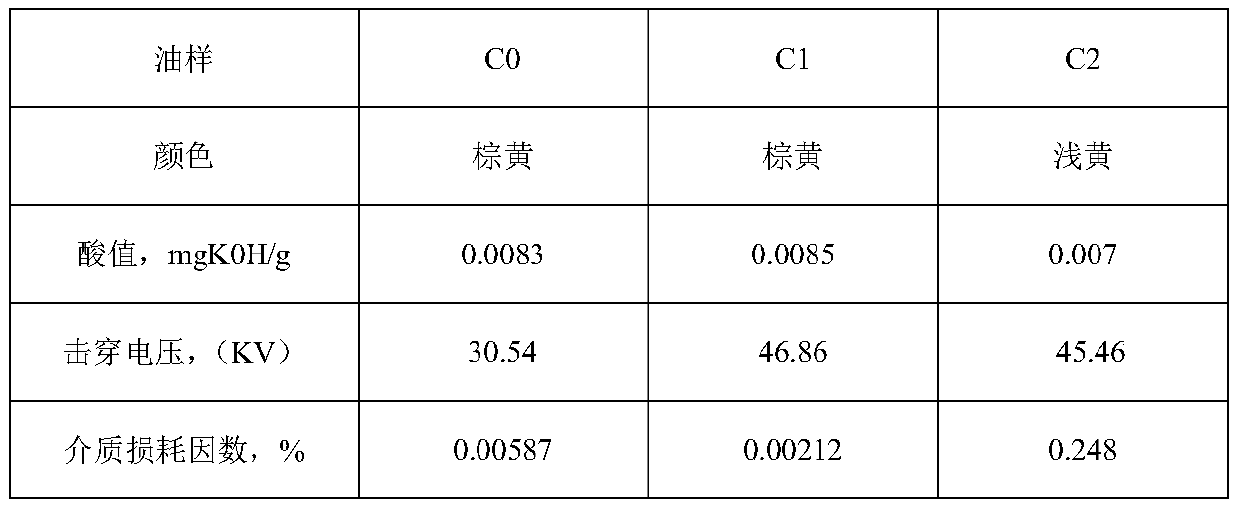

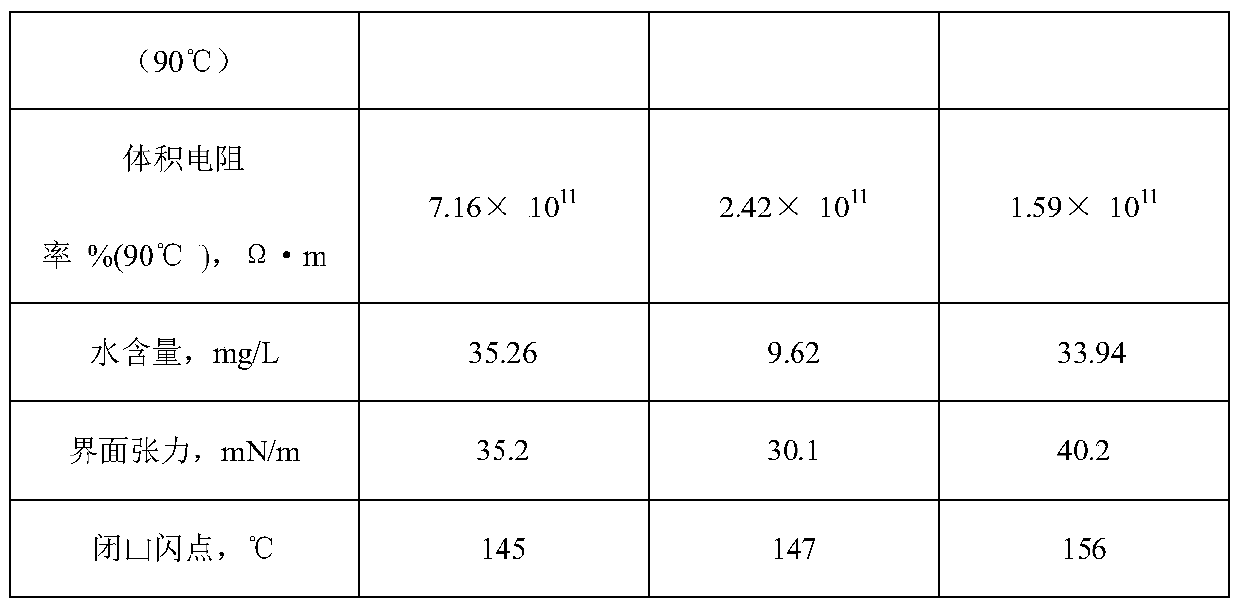

Disposal method for XDK adsorbent for waste transformer oil for standardized discharge

InactiveCN110860109AImprove adsorption capacityEffectively wash offIon-exchange process apparatusWater treatment parameter controlMuffle furnacePollutant

The invention relates to a disposal method for an XDK adsorbent for waste transformer oil for standardized discharge. The method includes the following steps: adding petroleum ether into 500 g of thewaste XDK adsorbent according to the mass ratio of the petroleum ether to the waste XDK adsorbent of 3:1, performing stirring for 10 min, and allowing the mixture to stand to obtain an upper layer mixed liquid I and a lower layer adsorbent washed by petroleum ether; adding pure water into the adsorbent washed by the petroleum ether, performing stirring for 10 min, and allowing the mixture to standto obtain an upper layer mixed liquid II and a lower layer washed adsorbent; performing petroleum ether recovery on the upper layer mixed liquid I and the upper layer mixed liquid II through a rotaryevaporator, pouring the obtained waste liquid into an oil-water separation tank for oil-water separation, and performing pollutant detection on the water obtained after treatment; and placing the washed adsorbent in a muffle furnace, and performing roasting to obtain a regenerated XDK adsorbent. After the regenerated XDK adsorbent adsorbs an oil sample, the improvement of the insulation performance is close to that of an oil sample adsorbed by a novel XDK adsorbent; and the regenerated XDK adsorbent has a better adsorption effect.

Owner:STATE GRID HUBEI ELECTRIC POWER CO XIAOGAN POWER SUPPLY CO

Preparation method of high-purity cefazolin sodium and medicinal preparation thereof

ActiveCN111548357AEasy to operateImprove product qualityAntibacterial agentsOrganic active ingredientsCefazolin SodiumPhosphate

The invention relates to a preparation method of high-purity cefazolin sodium and a medicinal preparation thereof, which belongs to the technical field of cefazolin sodium preparation, and the methodcomprises the following steps: 1) adding cefazolin acid into a phosphate solution, uniformly stirring, and controlling the temperature; 2) adding sodium carbonate into purified water, controlling thetemperature, stirring and dissolving; 3) slowly adding a sodium carbonate solution into the mixed solution of cefazolin acid, a phosphate solution and purified water, controlling the temperature and pH to dissolve the cefazolin acid to be clear, adding an adsorbent, stirring and filtering, and adjusting the pH; (4) adding ethylenediamine tetraacetic acid disodium and sodium chloride solid, coolingand growing crystals; and (5) filtering a cefazolin sodium crystallization solution, leaching and washing with a solvent, and drying. According to the invention, the method can effectively remove various impurities and polymers in cefazolin acid, the obtained product is high in purity and quality, and the prepared powder injection has higher medicinal safety.

Owner:NORTH CHINA PHARMA HEBEI HUAMIN PHARMA

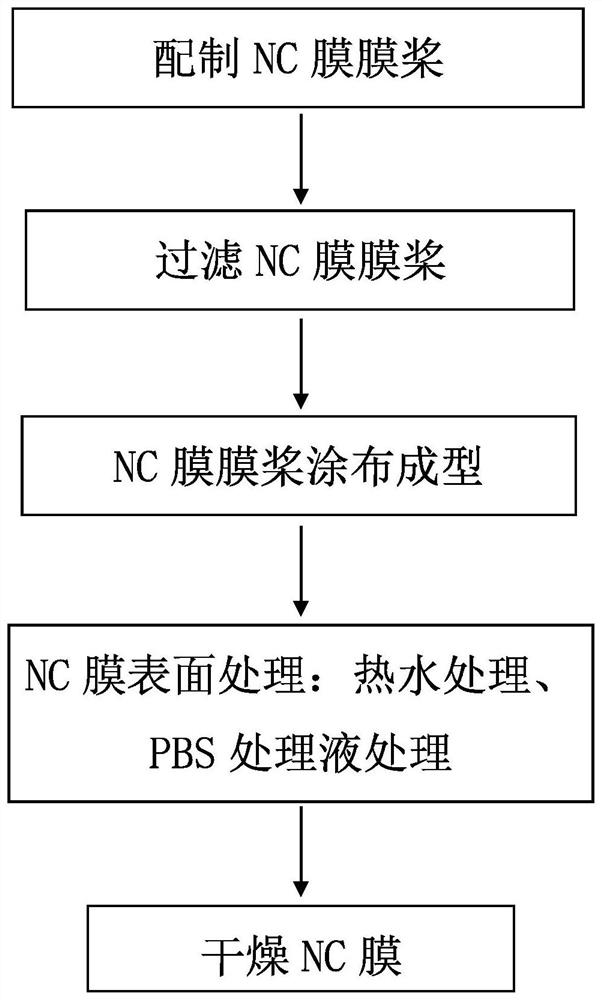

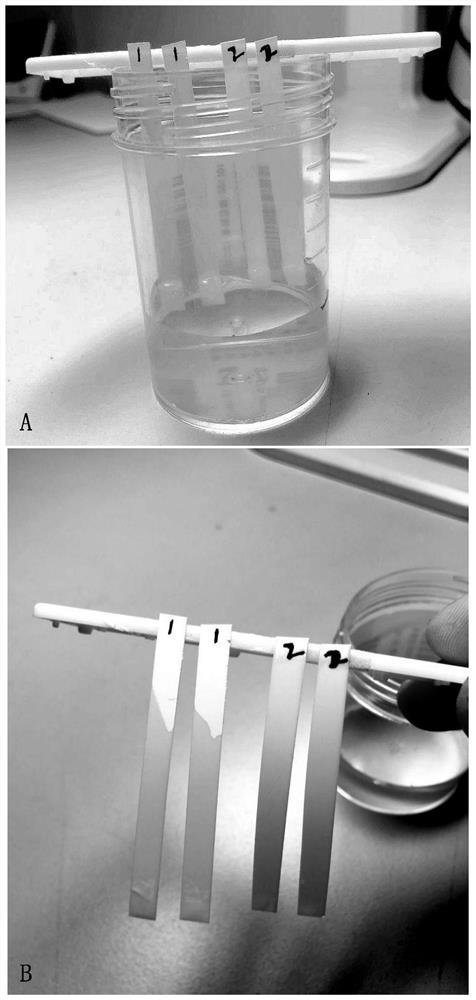

Preparation process of nitrocellulose membrane

The invention relates to the technical field of nitrocellulose membrane preparation, in particular to a preparation process of a nitrocellulose membrane, which comprises the following steps: (1) preparing nitrocellulose membrane slurry; (2) filtering the membrane slurry obtained in the step (1); (3) coating and forming the membrane slurry in the step (2), and preparing a nitrocellulose membrane, namely an NC membrane, by adopting a stepped heating mode; (4) treating the surface of a NC membrane; wherein the surface treatment of the NC membrane comprises the step of treating the surface of the NC membrane through hot water and PBS in sequence; and (5) drying the NC membrane. The preparation process can be applied to production of the NC membrane, bubbles and impurities generated by the NC membrane can be effectively reduced, and the production quality of the NC membrane is improved.

Owner:SHENZHEN CONNECTICUT BIOTECH

Preparation method of fruit detergent

InactiveCN104531400AEffectively wash offEffective pollutionOrganic detergent compounding agentsSurface-active detergent compositionsIsothiazolinoneWax

The invention provides a preparation method of a fruit detergent. The method comprises the following steps: (1) 80 parts of deionized water is added into a container, and 20 parts of vegetable oil and 4 parts of an emulsifying agent are added; the mixture is stirred until homogeneous liquid is formed; and (2) 0.2 parts of isothiazolinone, 0.2 parts of paraben, 3 parts of sodium chloride, 3 parts of sodium lauroyl glutamate, 3 parts of arginine, 1 part of tocopherol, and 1 part of an essence are added into the liquid obtained in the step (1); and stirring is continued until homogeneous liquid is formed. The preparation method is simple to operate. With the obtained fruit detergent, while dirt on fruits can be removed, wax on the fruits can be effectively removed. The detergent does not irritate skins, and is safe and non-toxic.

Owner:CHENGDU SHUNFA DISINFECTANT & WASHING TECH

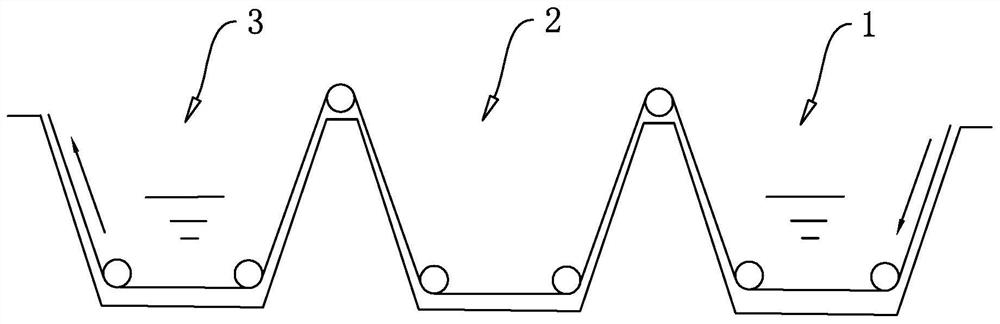

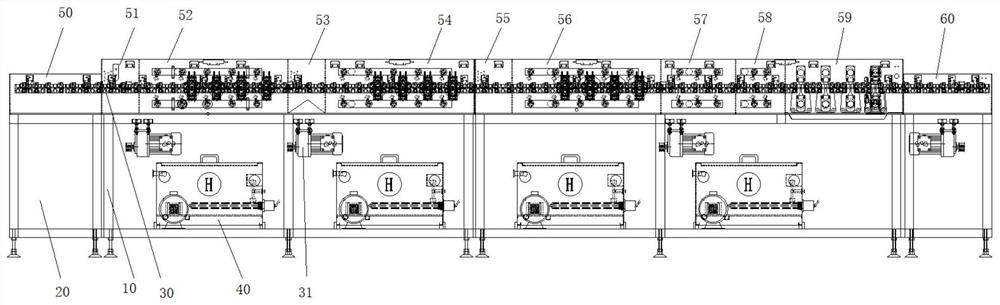

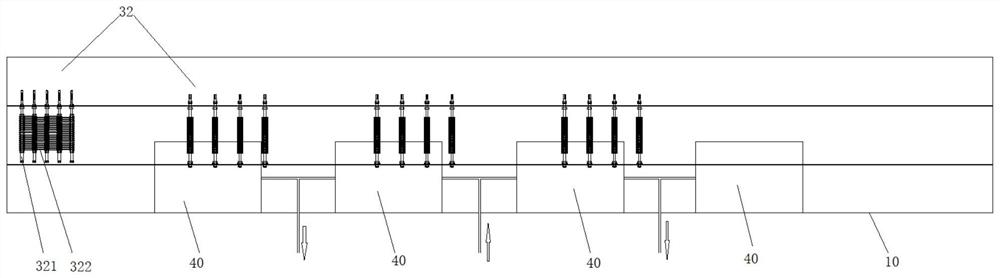

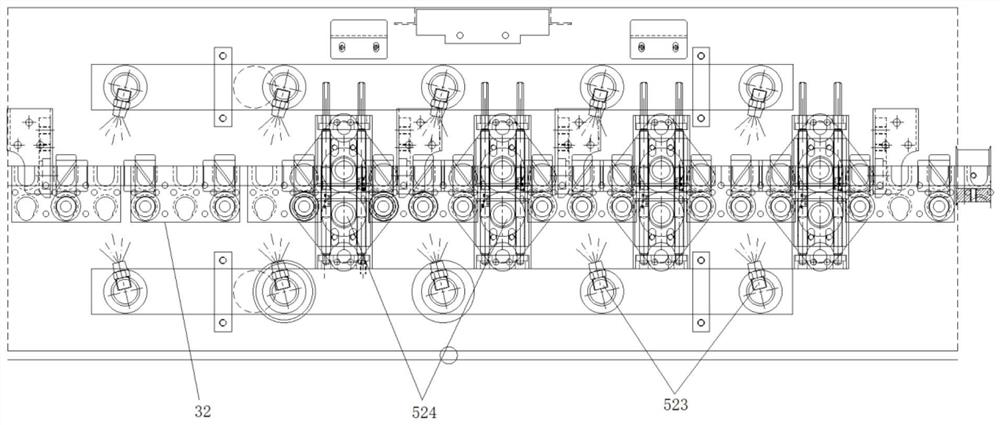

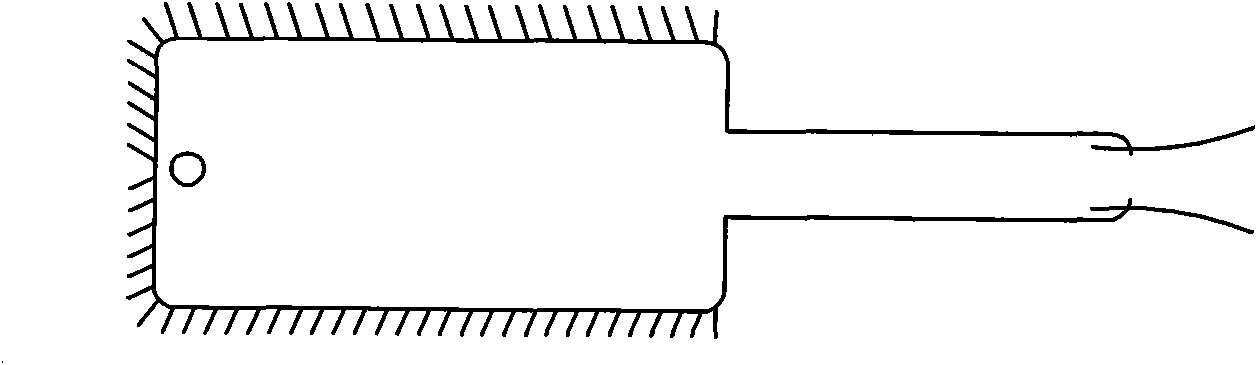

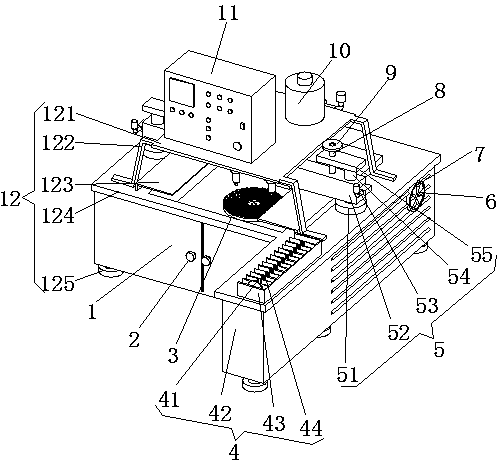

Small-size cover plate washing machine and washing method thereof

PendingCN111632936AKeep dryEffectively wash offDrying gas arrangementsCleaning using toolsWater useProcess engineering

The invention relates to the technical field of mechanical washing and discloses a small-size cover plate washing machine and a washing method thereof. The small-size cover plate washing machine comprises a rack and a control box; a feeding hole, a first wind shear chamber, a first washing area, a second wind shear chamber, a second washing area, a third wind shear chamber, a third washing area, afourth washing area, a fifth washing area, a fourth wind shear chamber and a discharging hole are sequentially arranged on the rack; a transmission mechanism and a water tank for water supply are further arranged on the rack; after a to-be-washed cover plate enters the washing machine, multiple times of deionized water washing and drying are sequentially carried out on the cover plate, then higher-purity deionized water washing and pure water washing are carried out on the cover plate, and finally, the cover plate is dried in the fourth wind shear chamber and is taken out of the discharging hole. When the cover plate is washed by the deionized water with higher and higher filtering precision most of impurities can be effectively washed away, and the cost of the washing water is saved; andfour groups of drying air knives in the fourth wind shear chamber and the angles of the drying air knives ensure that the cover plate is fully dried when reaching the discharging hole to meet the washing requirement.

Owner:SHENZHEN HANDONG GLASS EQUIP MFG CO LTD

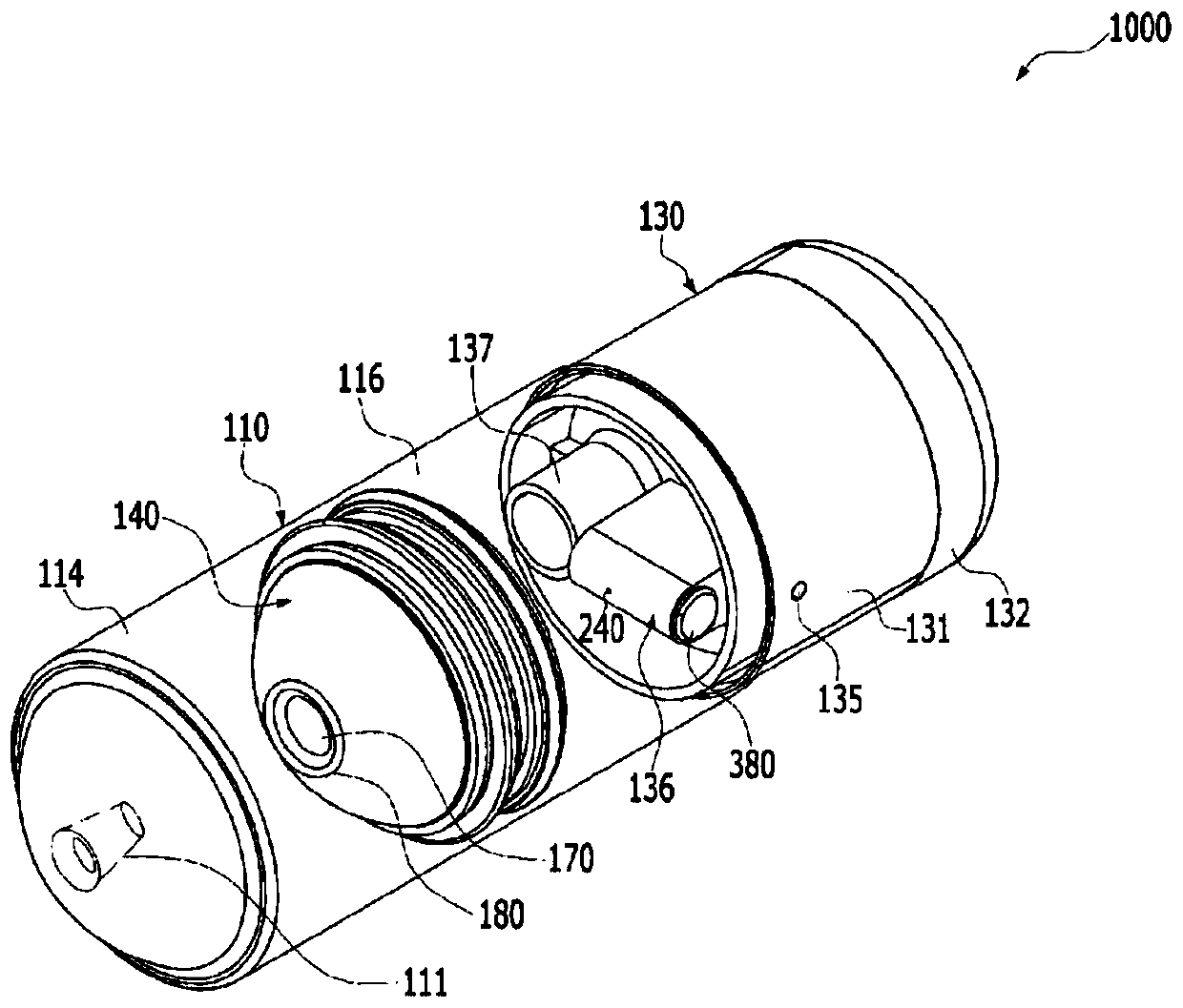

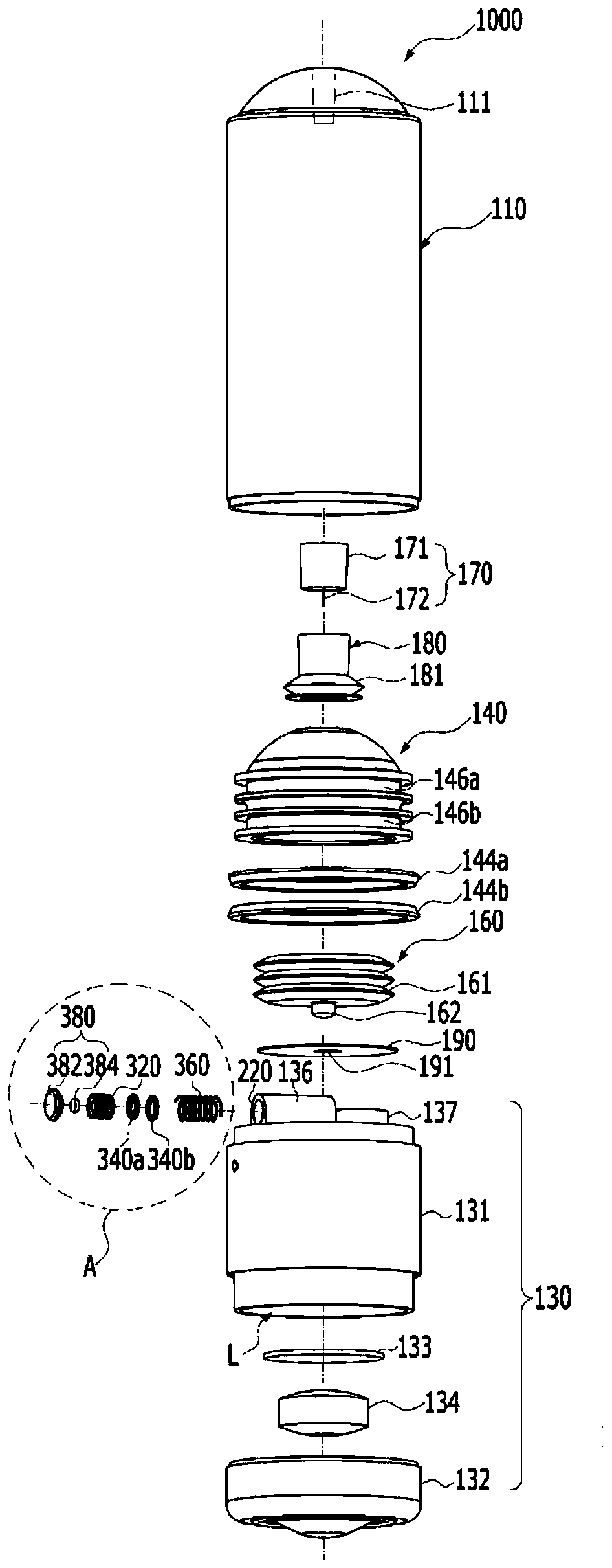

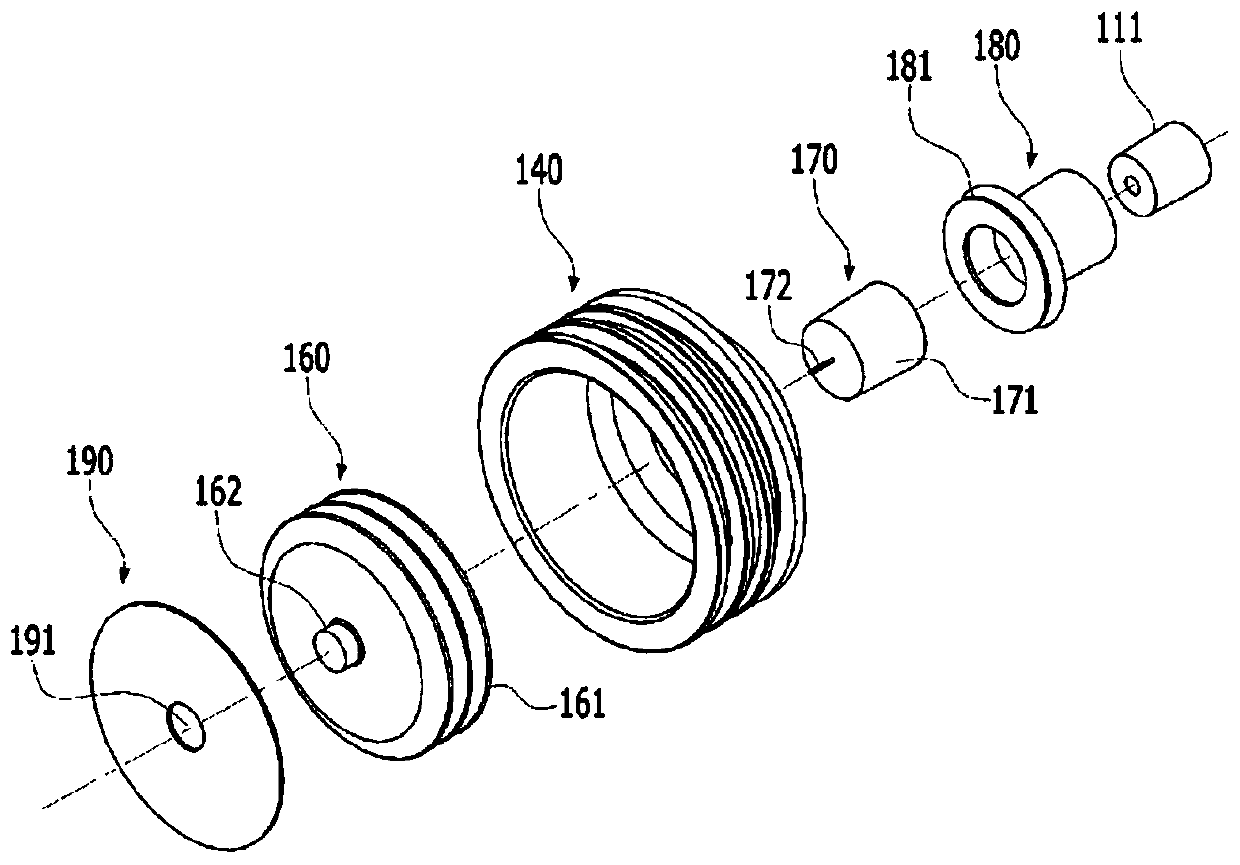

Liquid medicine injection apparatus capable of injecting additional fluid after completion of liquid medicine injection

ActiveCN109843359AAvoid inconvenienceEffectively wash offAmpoule syringesMedical devicesBiomedical engineeringPiston

The present invention provides a liquid medicine injection apparatus capable of injecting an additional fluid after completion of liquid medicine injection. A liquid medicine injection apparatus capable of injecting an additional fluid after completion of liquid medicine injection according to an embodiment of the present invention comprises: a cylinder lengthily extending in one direction and having a nozzle formed at one end thereof; a piston installed inside the cylinder to be movable in an airtight manner along the one direction and being capable of forming a liquid medicine storage spacewhich is filled with the liquid medicine introduced through the nozzle; an injector moving the piston and disposed at the other end of the cylinder; a fluid tank storing a fluid in a sealed state, disposed movably inside the cylinder so as to be movable with the piston, and being deformable by a pressure; a needle unit disposed between the nozzle and the fluid tank and passing through a part of the fluid tank to enable communication therebetween; and a cap member disposed between the needle unit and the fluid tank and being deformable to allow the needle unit to pass through the fluid tank.

Owner:EWHA MEDITECH CO LTD

Fruit detergent

InactiveCN104450337AGuaranteed validityGuaranteed shelf lifeSurface-active non-soap compounds and soap mixture detergentsBiotechnologyMonosodium glutamate

The invention provides a fruit detergent. The fruit detergent is prepared from the following components in parts by weight: 20-25 parts of vegetable oil, 0.5-0.8 part of isothiazolinone, 3-5 parts of sodium chloride, 4-8 parts of an emulsifier, 3-5 parts of sodium lauroyl glutamate, 3-5 parts of arginine, 1-3 parts of tocopherol, 1-3 parts of an essence and 80-120 parts of deionized water. The fruit detergent provided by the invention is used for washing off dirts one fruits and effectively removing wax on fruits, is not irritant to skin and is safe and non-toxic.

Owner:CHENGDU SHUNFA DISINFECTANT & WASHING TECH

Cleaning equipment for plastic toys for children

InactiveCN108543759AEffectively wash offImprove cleaning efficiencyCleaning using toolsCleaning using liquidsEngineering

Owner:王康

Bio-enzyme treatment equipment for wool

ActiveCN108588845AEasy to handleImprove efficiencyWool fibre washing/scouringLiquid/gas/vapor removalActivated carbonElution

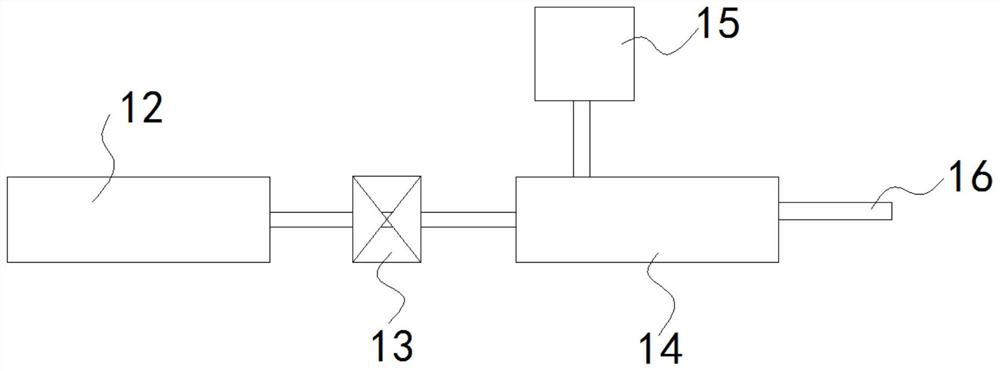

The invention discloses bio-enzyme treatment equipment for wool. The equipment comprises a cleaning device, a bio-enzyme treatment device and an elution device, wherein the cleaning device comprises afirst drum, an eccentric roller and an activated carbon spraying unit, a rolling space exists between the roller and the inner wall of the drum, the eccentric roller rolls wool in the rolling space,and the activated carbon spraying unit sprays activated carbon to the rolling space; the bio-enzyme treatment device comprises a box body and rolling units, concaved parts are formed in the inner wallof the box body, and the rolling units can be rotationally matched in the concaved parts and bulge out of the inner wall of the box body; the elution device comprises a second drum, a second cylinder, a brush unit and an ultrasonic generator; the upper end of the second drum is butted against the lower end of the box body, the second drum and the second cylinder are driven by a power mechanism torotate oppositely, a space for accommodating wool is formed between the second drum and the second cylinder, the brush unit is used for brushing wool during opposite rotation of the second drum and the second cylinder, and a drainage pipe is arranged on the second drum and communicated with a water pump to pump away water.

Owner:乐陵市蒙绒畜产品有限公司

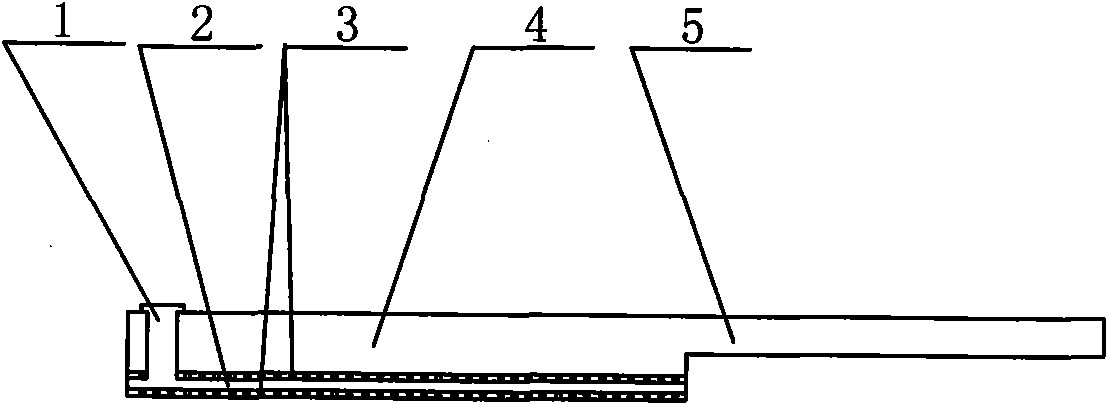

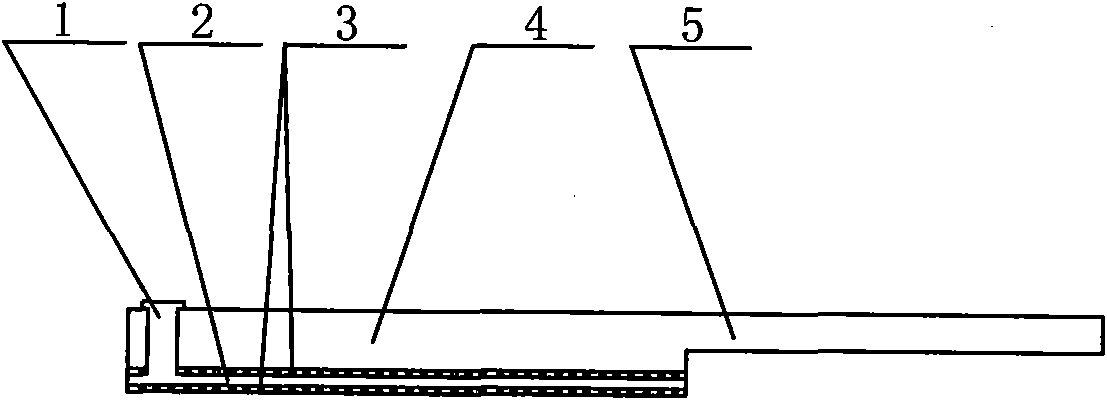

Novel car washing brush

InactiveCN102309131AEffectively wash offBrushesCleaning apparatus for vehicle exteriorsLiquid layerWater source

The invention discloses a novel car washing brush, and relates to the field of car washing, in particular to a novel car washing brush. The novel car washing brush comprises a liquid injecting port (1), a washing liquid layer (2), small spraying holes (3), a water storage layer hair brush black plate (4) and a drainage tube handle (5), wherein one end of the drainage tube handle (5) is connected in the water storage layer hair brush black plate (4); the lower layer of the water storage layer hair brush black plate (4) is provided with two layers of small spraying holes (3); the washing liquid layer (2) is arranged between the small spraying holes (3) at the two sides; and the front end of the water storage layer hair brush black plate (4) is provided with the liquid injecting port (1) which extends into the washing liquid layer (2) from the outer end. In the novel car washing brush, car washing liquid is blended into the car washing brush and is connected with a water source, and the dirt difficult to remove on the surface of a car body is effectively washed, so that the novel car washing brush is more convenient and faster.

Owner:杨明强

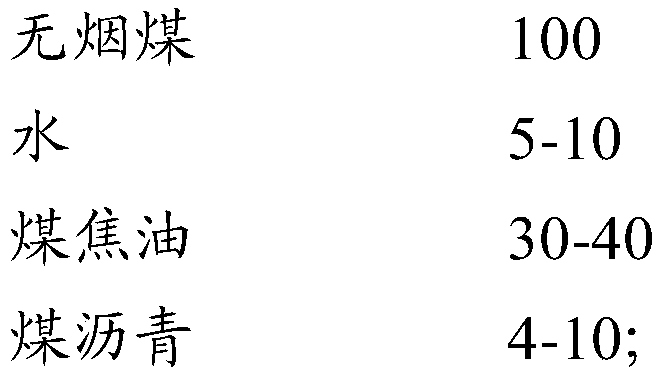

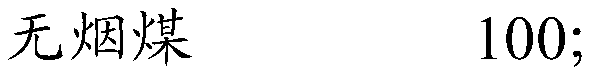

Preparation method for coal-based vinyl acetate carrier carbon

ActiveCN110182804AGood molding effectGood lookingCatalyst carriersOrganic compound preparationVolatilesSmallerThan

The invention provides coal-based vinyl acetate carrier carbon and a preparation method. The raw materials of coal-based vinyl acetate carrier carbon comprise the following substances in parts by weight: 100 parts of anthracite, 5-10 parts of water, 30-40 parts of coal tar and 4-10 parts of coal tar pitch, wherein the anthracite is pulverized anthracite powder with particle size D90 being smallerthan 75 mu m, and contains less than 3.5wt% of ash and less than 9wt% of volatiles; the coal tar comprises less than 0.5wt% of ash and less than 50wt%-60wt% of pitch; the coal tar pitch comprises lessthan 1wt% of ash and has softening temperature being 95-120 DEG C. The preparation method comprises the following steps: kneading layering, carbonizing, primary activation, secondary activation, washing and drying. Coal-based vinyl acetate carrier carbon has high strength and high adsorption capacity to zinc acetate; the preparation method can increase activation yield and improve product performance.

Owner:CHNA ENERGY INVESTMENT CORP LTD +1

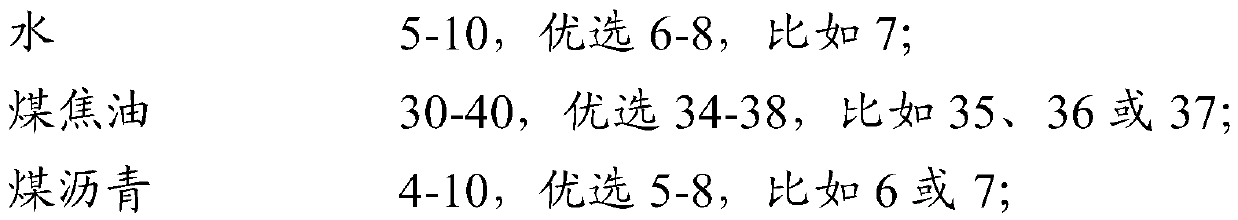

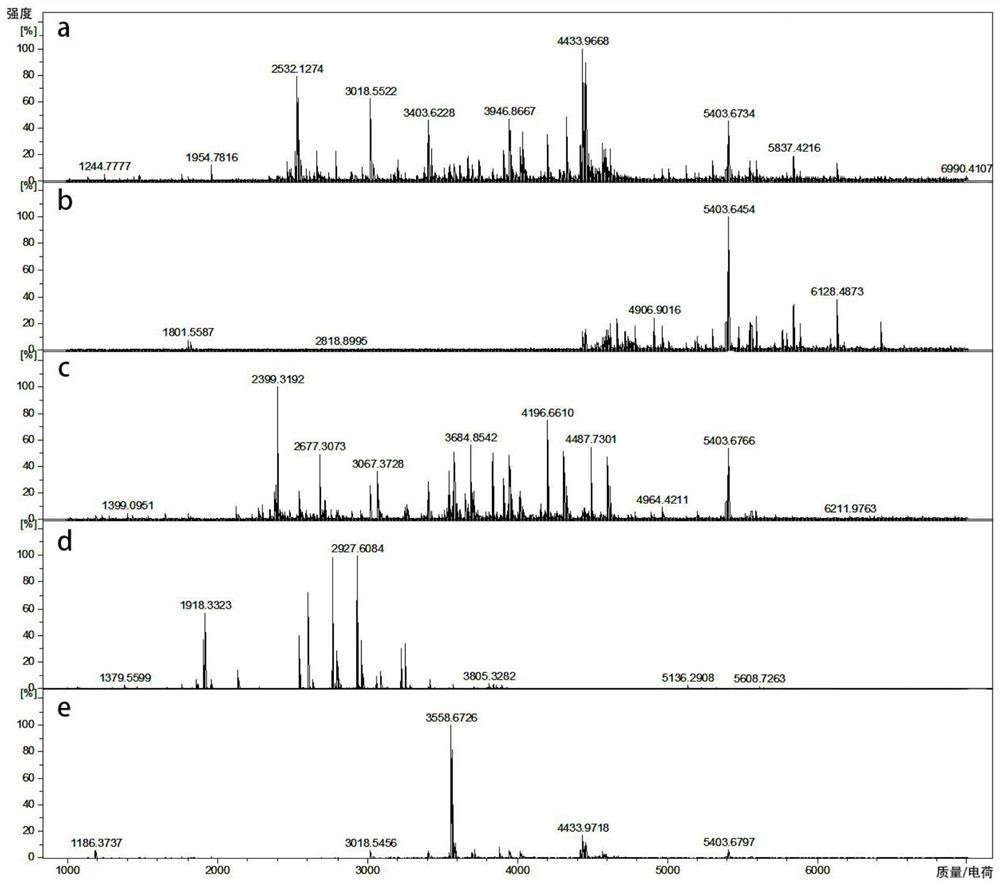

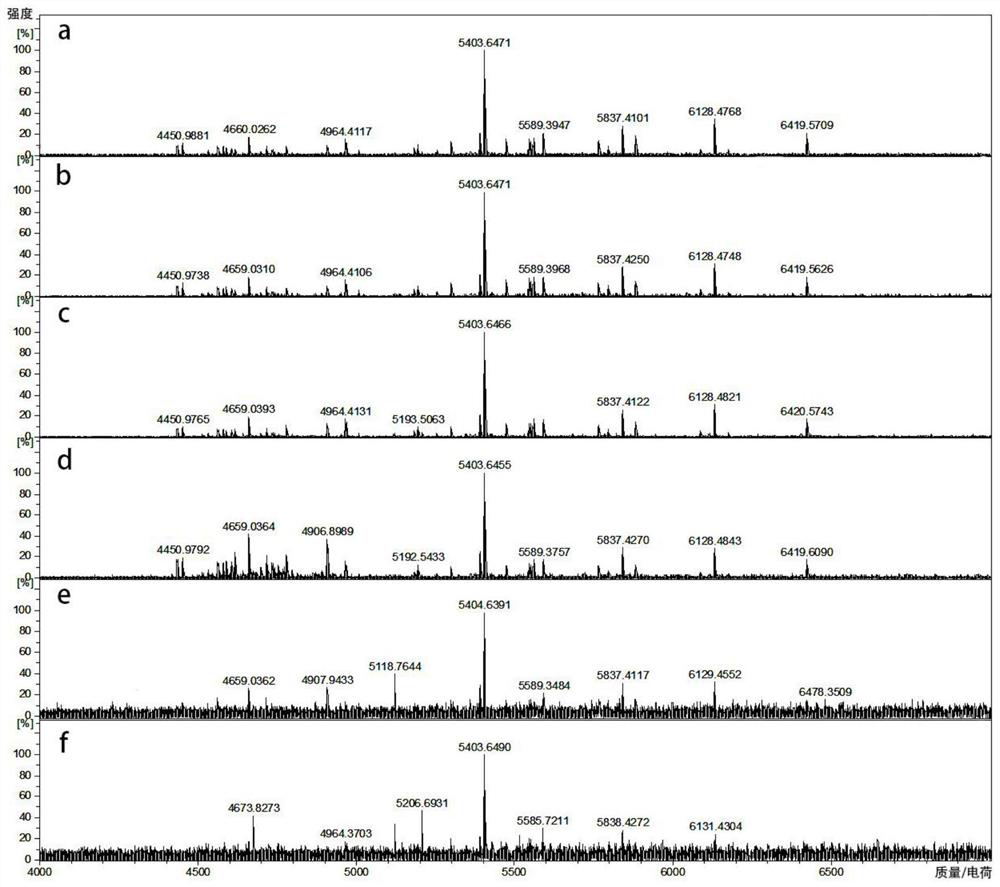

Preparation method and application of glycopeptide-enriched magnetic polyaniline nano material

ActiveCN112444437AImprove enrichment effectReduce sizePreparing sample for investigationSodium acetateEnzyme digestion

The invention discloses a preparation method and application of a glycopeptide-enriched magnetic polyaniline nano material, wherein the magnetic polyaniline nano material is prepared by firstly heating ferric trichloride hexahydrate, ethylene glycol and anhydrous sodium acetate at high temperature to obtain a magnetic nano material, and then coating polyaniline on the surface of the magnetic nanomaterial. The glycopeptide enrichment method comprises the following steps: adding a magnetic polyaniline nano-material dispersion liquid into a glycoprotein pancreatin enzyme digestion product, and carrying out oscillation enrichment; and after the enrichment liquid is subjected to magnetic separation, adding eluent into the glycopeptide-enriched magnetic polyaniline nanometer material for oscillation elution, and then carrying out magnetic separation to obtain a glycopeptide enrichment solution. According to the material and the method, richer protein glycosylation modification information and more accurate glycan glycoform can be obtained, low-cost, environment-friendly and high-specificity enrichment and separation are achieved under the condition that the protein glycosylation modification structure is not damaged, operation is easy and convenient, and a novel material and a technical method are provided for protein glycosylation modification research in a complex sample, screening of related tumor markers and the like.

Owner:THE INST OF BASIC MEDICAL SCI OF CHINESE ACAD OF MEDICAL SCI

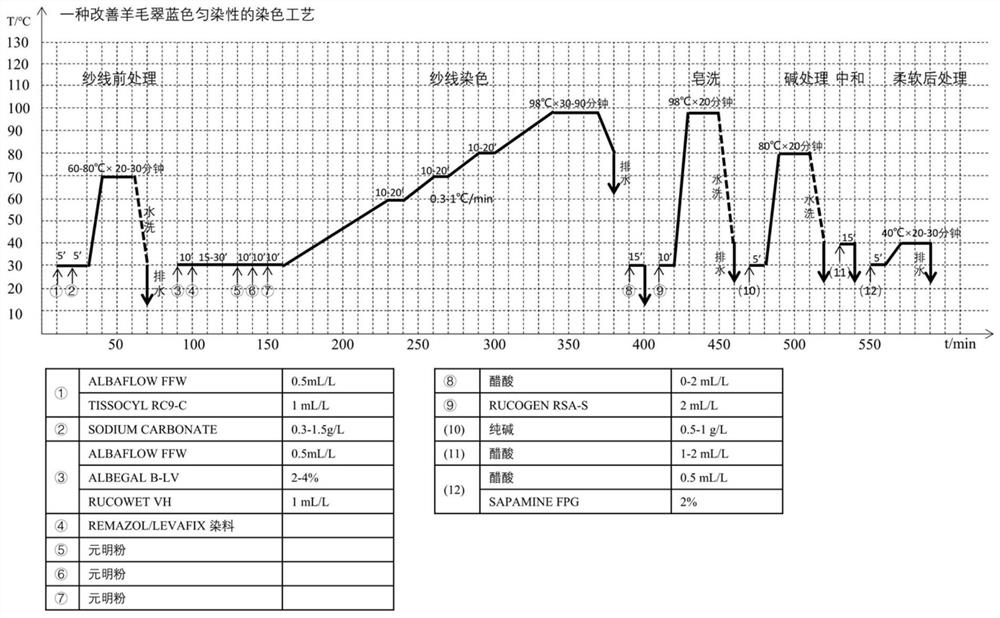

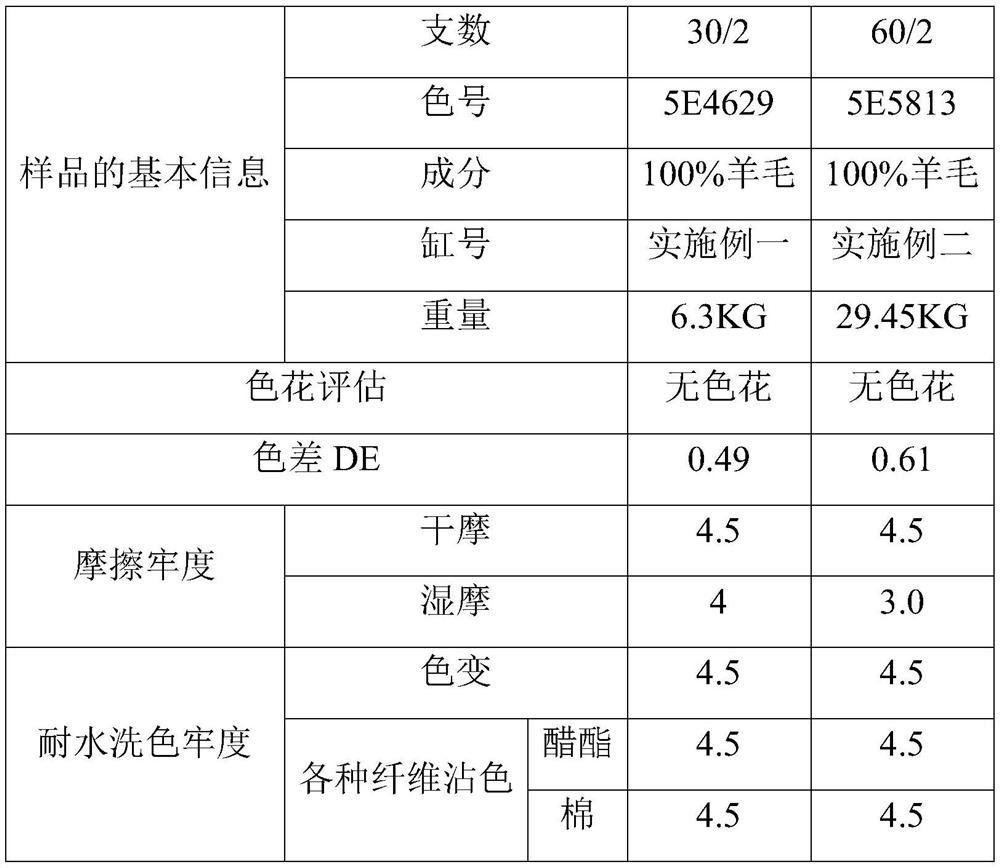

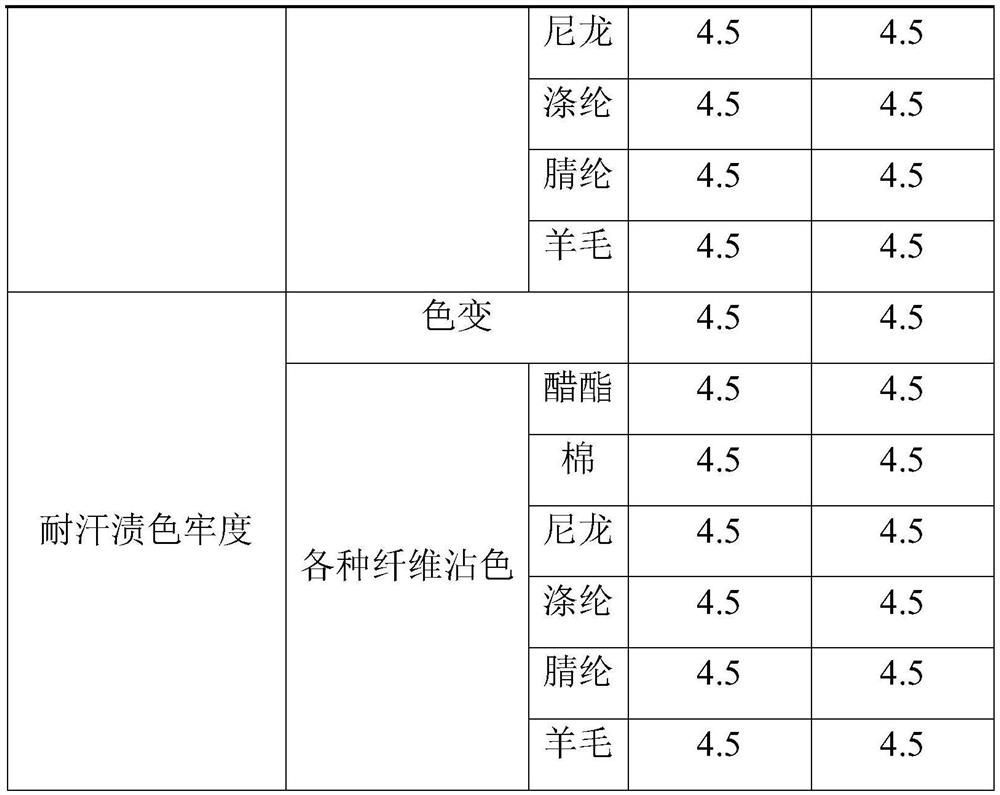

Dyeing process for improving turquoise blue leveling property of wool

PendingCN113073483AControl Shading RateGood penetration and migration performanceDry-cleaning apparatus for textilesDyeing processYarnPulp and paper industry

The invention discloses a dyeing process for improving turquoise blue leveling property of wool. The dyeing process comprises the following steps: 1) yarn pre-treating; 2) yarn dyeing; 3) soaping; 4) alkali washing; 5) neutralizing; and 6) softening treatment. The invention belongs to the technical field of wool dyeing, and particularly relates to a dyeing process for improving turquoise blue leveling property of wool. REMAZOL / LEVAFIX cotton reactive dye with a small molecular weight is selected to replace LANASOL / NOVACRON wool reactive dye to dye wool fibers, the dye has better permeation and migration performance, anhydrous sodium sulphate is added in three times, the dosage of the anhydrous sodium sulphate is gradually increased, and meanwhile, a dyeing heating rate is controlled to control a coloring rate of turquoise blue, so that the leveling property of dyeing is improved, and the probability of defects such as dyeing defects, inner and outer layer difference and color difference is reduced; and through soaping, alkali washing and multiple times of water washing, flooding on the surface of the fibers can be effectively washed away, and therefore it is guaranteed that various fastnesses after dyeing can meet clothing requirements.

Owner:ZHANGJIAGANG YANGZI DYEING & FINISHING CO LTD

Mild skin-care body wash for children and preparation method thereof

InactiveCN107456408ASafeguard ModerationIncrease choiceCosmetic preparationsToilet preparationsBetaineLanolin

The invention provides a mild skin-care body wash for children and a preparation method thereof and relates to the field of daily cleaning supplies. The mild skin-care body wash consists of the following raw materials by mass percent: 10-20% of glyceride-based alkyl amido betaine, 3-8% of tea tree essential oil, 3-7% of lanolin alcohol, 3-7% of a biological bactericide and the balance of water, wherein the structural formula of glyceride-based alkyl amido betaine is R-CO-NH-(CH2)3-N+(CH3)2-CH2-COO-; and R is a glyceride base provided by glyceride. According to the mild skin-care body wash, glyceride-based alkyl amido betaine obtained through connecting the glyceride base with alkyl amido betaine is endowed with favorable tenderness, and can generate rich and fine foams; further, in cooperation with tea tree essential oil, lanolin alcohol and the biological bactericide, the prepared body wash has favorable mild cleaning property, sterilization and disinfection performance and skin-care effect, can effectively wash off dirt and dust on the skin, meanwhile, moistens the skin, relieves dryness, keeps the skin clean, comfortable and tender, and does not injure the delicate skin of children.

Owner:CHENDU NEW KELI CHEM SCI CO LTD

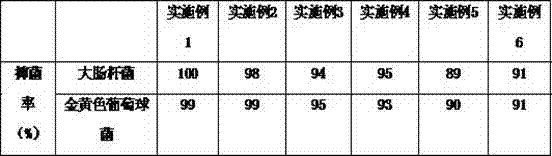

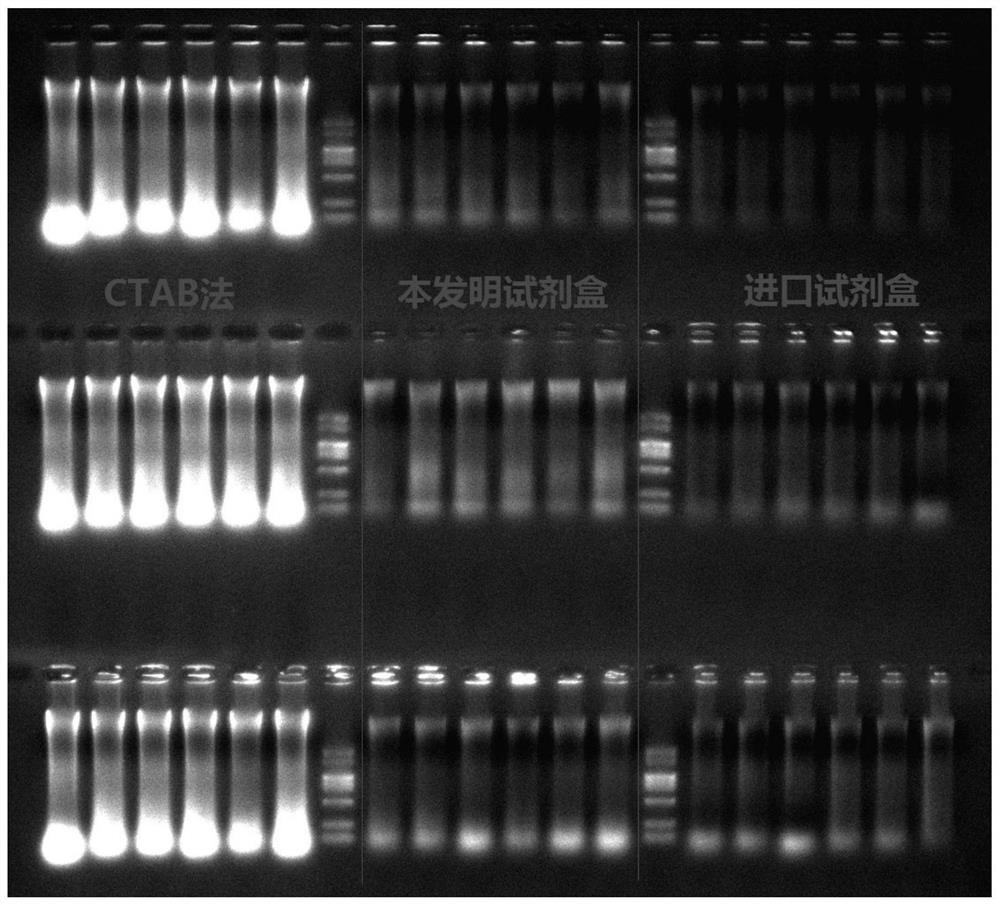

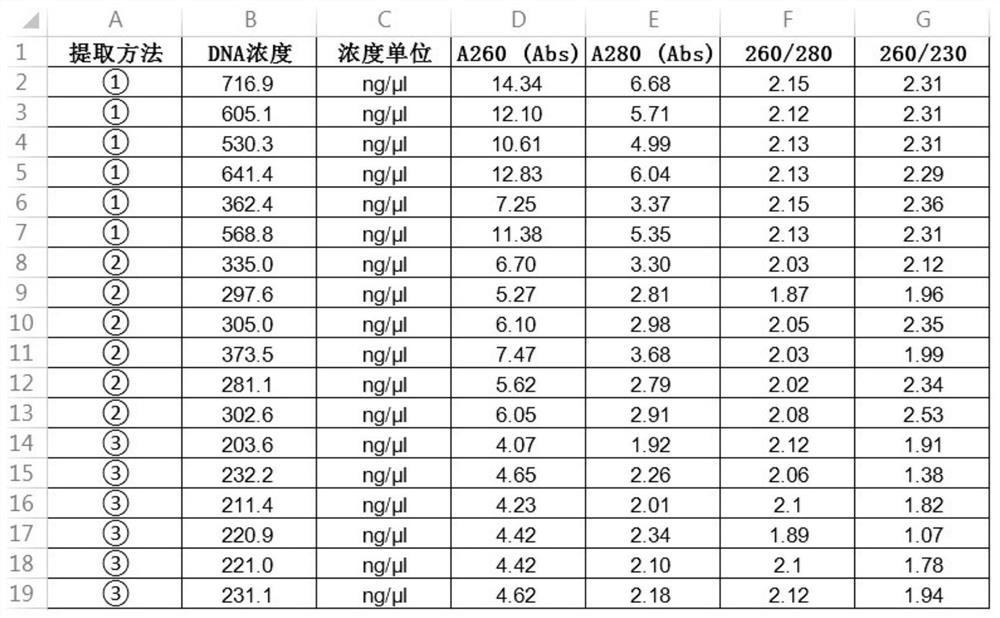

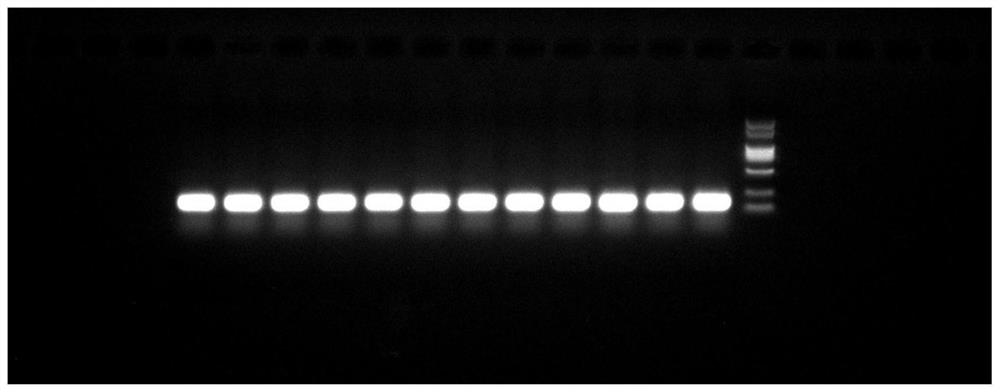

Plant tissue genome dna extraction kit and high-throughput extraction method

ActiveCN112779247BQuality improvementLow costFood processingDNA preparationBiotechnologyPlant tissue

Owner:YUAN LONGPING HIGH TECH AGRI CO LTD +1

Novel Artificial Marble

InactiveCN102935738BWith self-cleaning functionWith cleanLayered productsCeramic shaping apparatusResin adhesiveWaste material

The invention provides a novel artificial marble and manufacturing method thereof. The novel artificial marble comprises a body layer composed of a filling material and a resin adhesive material, a coating layer containing titanium dioxide or a mixed coating comprising titanium dioxide. The surface of the novel artificial marble has a titanium dioxide coating film or a coating containing titanium dioxide or the mixed coating comprising titanium dioxide, so that the artificial marble has a self-cleaning function, and can greatly reduce cost for maintaining clean when the artificial marble is used as a building material. Due to the excellent ultraviolet absorption function of titanium dioxide, decomposition of the component materials of the artificial marble can be effectively prevented; mechanical performance of the artificial marble can be maintained; and fractures / cracks can be prevented from appearance. The particles or powder of the main raw materials of the artificial marble are inorganic waste materials of buildings and livings and even waste materials of the artificial marble, thereby reducing cost, decreasing resource waste and protecting the environment.

Owner:张磊

Wool fiber biotechnology processing equipment

ActiveCN108531993BEasy to handleImprove efficiencyWool fibre washing/scouringAnimal materialActivated carbonMechanical engineering

The invention discloses equipment for processing wool fiber through biotechnology. The equipment comprises a cleaning device, a biological enzyme processing device and an eluting device, wherein the cleaning device comprises a first roller, an eccentric pin roller and an active carbon spraying unit, a rolling space is formed between the pin roller and an inner wall of the roller, the eccentric pinroller is used for rolling wool in the rolling space, and the active carbon spraying unit is used for spraying active carbon towards the rolling space; the biological enzyme processing device comprises a tank body and a rolling unit, an inner wall of the tank body is provided with a groove, the rolling unit is rotationally matched with the interior of the groove and protrudes out of the inner wall of the tank body; the eluting device comprises a second roller, a second column, a hairbrush unit and an ultrasonic wave generator; the upper end of the second roller is in butt joint with the lowerend of the tank body, the second roller and the second column are driven by a power mechanism to rotate in opposite directions, a space for accommodating the wool is formed between the second rollerand the second column, and the hairbrush unit is used for washing and brushing the wool when the second roller and the second column rotate in opposite directions.

Owner:钟文宇

Ceramic membrane washing equipment and method for synthesizing Beta molecular sieve based on organic template-free method

PendingCN113413765AGuaranteed purityEasy to replaceSemi-permeable membranesCrystalline aluminosilicate zeolitesMolecular sieveEngineering

The invention provides ceramic membrane washing equipment and method for synthesizing a Beta molecular sieve based on an organic template-free method, the ceramic membrane washing equipment comprises a shell and a washing assembly, a fixing plate is mounted between two sides of the inner wall of the shell, a placing groove is formed in the top of the fixing plate, the washing assembly is placed in the placing groove, the washing assembly comprises a bottom plate, a frame is mounted at the top of the bottom plate, a ceramic membrane is arranged on the inner surface of the frame, a top plate is mounted at the top of the frame, a feeding port is formed in the top of the top plate, a first thread is arranged on the outer surface of the feeding port, and a discharging port is formed in the right side of the frame. According to the ceramic membrane washing equipment and method for synthesizing the Beta molecular sieve, impurities in a molecular sieve crude product can be effectively washed away, the purity of molecular sieve slurry is guaranteed, and replacement is facilitated through detachable connection of the washing assemblies.

Owner:JIANGSU TIANNUO NEW MATERIAL TECH

A kind of preparation method of high-purity cefazolin sodium and pharmaceutical preparation thereof

ActiveCN111548357BEasy to operateImprove product qualityAntibacterial agentsPowder deliveryCefazolin SodiumPhosphate

The invention relates to a preparation method of high-purity cefazolin sodium and a pharmaceutical preparation thereof, belonging to the technical field of cefazolin sodium preparation, comprising the following steps: 1) putting cefazolin acid into a phosphate solution and stirring evenly , control the temperature; 2) Put the sodium carbonate into the purified water, control the temperature, and stir to dissolve; 3) Slowly add the sodium carbonate solution to the mixture of cefazolin acid, phosphate solution and purified water, control the temperature, pH, Dissolve cefazolin acid, add adsorbent to stir and filter, and adjust pH; 4) Add disodium edetate and sodium chloride solid, cool down and grow crystals; 5) Filter cefazolin sodium crystal solution, and use solvent Dip washing and drying. The invention can effectively remove various impurities and polymers in the cefazolin acid, and the obtained product has high purity and good quality, and has higher medicinal safety after being made into a powder injection.

Owner:NORTH CHINA PHARMA HEBEI HUAMIN PHARMA

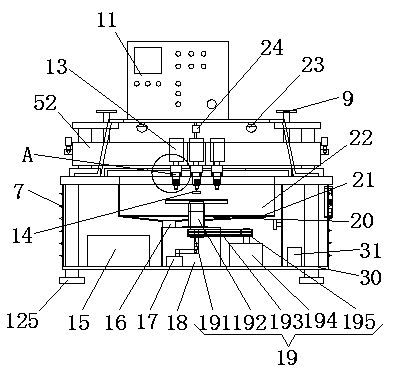

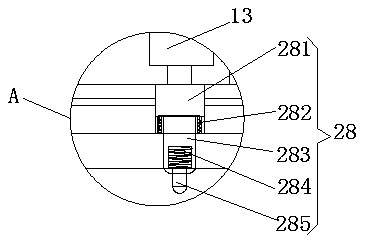

High-precision grinding machine for plane machining of sealing element

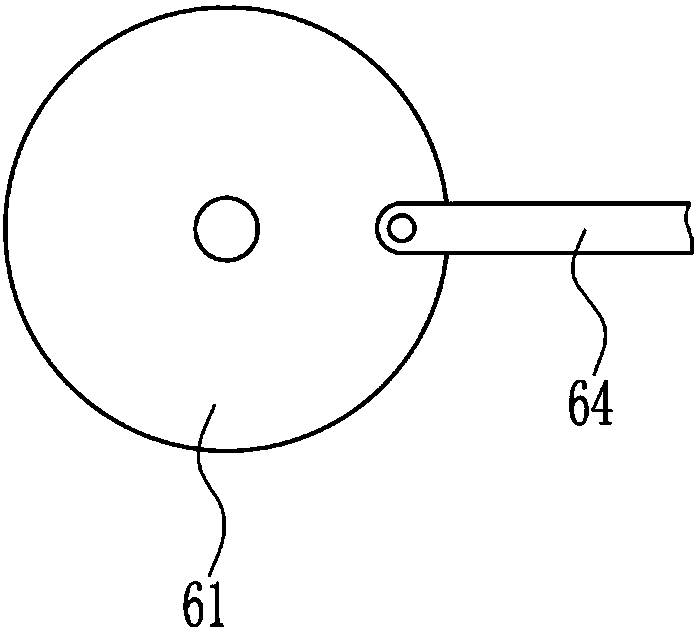

PendingCN111318929AStable supportAvoid affecting the machining accuracyAbrasive surface conditioning devicesAutomatic grinding controlCircular discEngineering

The invention discloses a high-precision grinding machine for plane machining of a sealing element. The high-precision grinding machine comprises a tool box unit, an adjusting unit, a supporting unit,a power unit and a pressing structure; the supporting unit comprises a bearing table, supporting legs are arranged on the lower surface of the bearing table, a bottom plate is arranged between the supporting legs, a grinding chamber is formed in the center of the lower surface of the bearing table, an opening corresponding to the grinding chamber is formed in the upper surface of the bearing table, a protective cover is arranged on the edge of the opening of the bearing table, a control platform is arranged above the protective cover, Z-shaped supporting plates are arranged at the four corners of the control platform, and the lower ends of the Z-shaped supporting plates are connected with the bearing table; and the adjusting unit comprises a disc, and an adjusting arm is arranged above the disc. According to the high-precision grinding machine for plane machining of the sealing element, the operation is easy, the operation process is simplified, the grinding efficiency is high, the equipment cost is saved, the labor force is reduced, the production efficiency is greatly improved, and the precision of the ground sealing element is high.

Owner:济源创新石化配件有限公司

Distance measuring device

ActiveCN109959338ADoes not significantly affect optical propertiesEffectively wash offSemiconductor/solid-state device testing/measurementGrinding feed controlLight beamEngineering

The application discloses a distance measuring device. The distance measuring device comprises a measuring head 20, the measuring head 20 having an optical measuring system 1 for carrying out an optical measurement process on a measurement object 4 by means of at least one measuring light beam 5 formed from a broad-band measuring light. The measuring head 20 further has a liquid guide 2 with a liquid inlet 28 and a liquid outlet 27 for producing a jet of liquid directed at the measurement object 4, the liquid guide 2 being designed such that in certain sections at least the measuring light beam 5 runs essentially along the jet of liquid. The measuring head 20 further has a flow element 3 with a laminar flow channel 8, the flow element 3 being designed such that the at least one measuring light beam 5 is able to reach the measurement object 4 by passing through the laminar flow channel 8.

Owner:PRECITEC OPTRONIK GMBH

Nitrogen-free phosphorus-free oil-removing wax-removing cleaning agent

The invention belongs to the technical field of cleaning agents, and particularly relates to a nitrogen-free phosphorus-free oil-removing wax-removing cleaning agent. The nitrogen-free phosphorus-freeoil-removing wax-removing cleaning agent comprises the following ingredients, in parts by weight, of 0.1-10 parts of surfactants, 0.01-25 parts of dispersing agents, 0.1-10 parts of regulating agentsand 50-75 parts of water. The nitrogen-free phosphorus-free oil-removing wax-removing cleaning agent is a concentrated weakly alkaline liquid environment-friendly cleaning agent free of ammonia nitrogen and phosphate, by means of the cleaning agent, oil stains can be easily rinsed from the surface of metal, wax is polished, polishing paste on the surface of a workpiece can be effectively washed away without causing adverse effects on the surface of the polished workpiece, and a good cleaning effect can be achieved by raising the temperature or increasing the concentration.

Owner:上海王圣化工科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com