Ceramic membrane washing equipment and method for synthesizing Beta molecular sieve based on organic template-free method

A washing equipment and stencil agent technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of affecting the adsorption effect, affecting the quality of the adsorbent, and impurities in the molecular sieve slurry, so as to ensure the purity, The effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

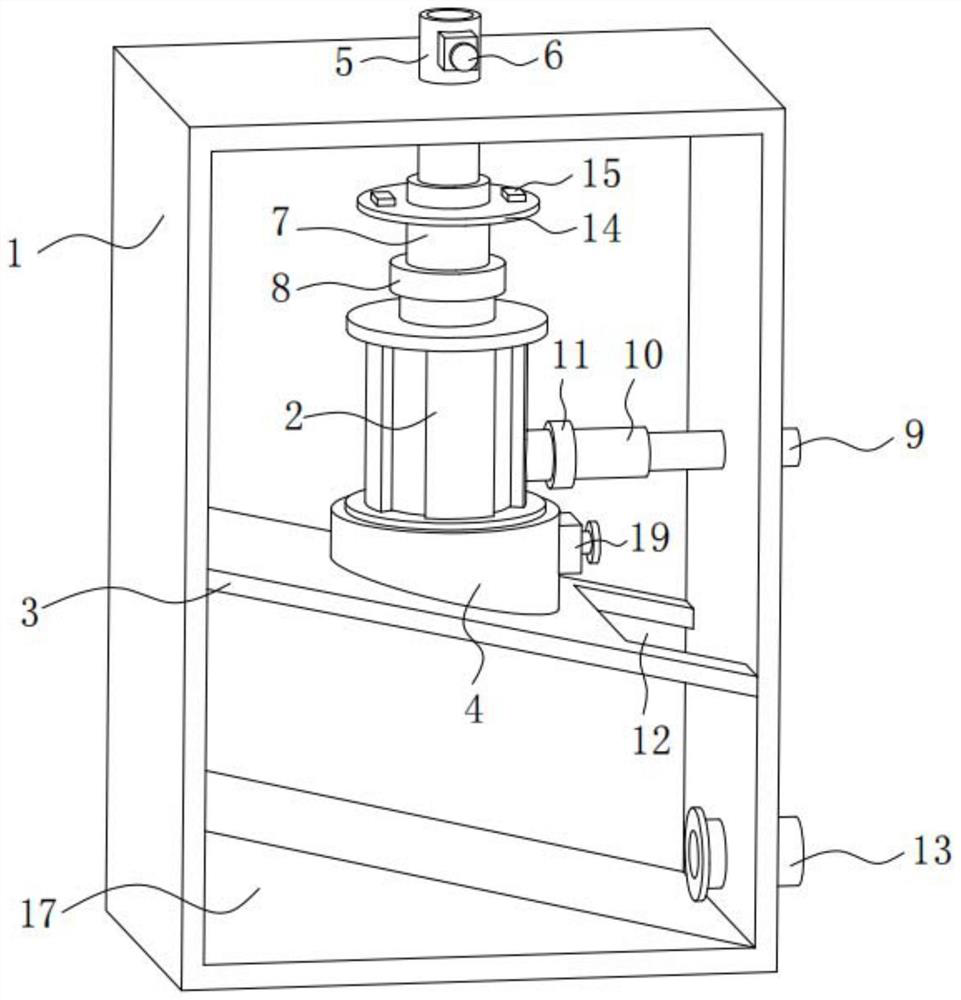

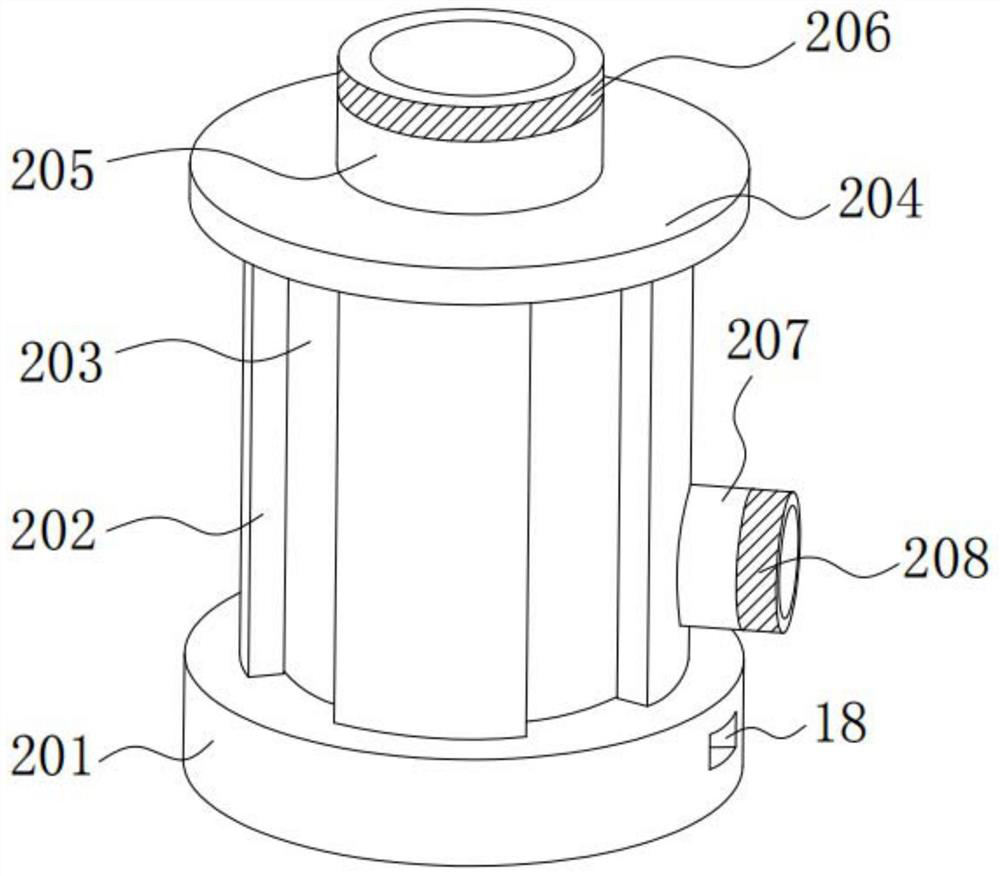

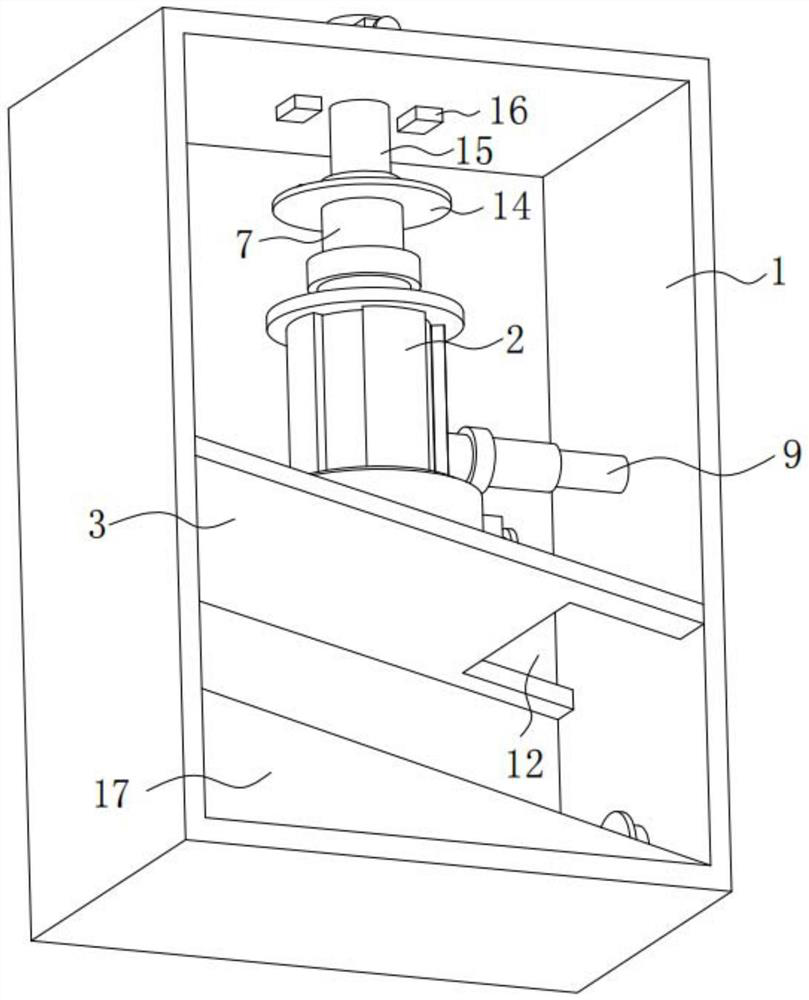

[0030] Please refer to Figure 1-Figure 6 As shown, wherein, the ceramic membrane washing equipment based on the synthesis of Beta molecular sieves without organic template method includes a shell 1 and a washing assembly 2, and a fixed plate 3 is installed between the two sides of the inner wall of the shell 1, and the fixed plate 3 The top is equipped with a placement tank 4, the washing assembly 2 is placed inside the placement tank 4, the washing assembly 2 includes a bottom plate 201, a frame 202 is installed on the top of the bottom plate 201, and the inner surface of the frame 202 is provided with There is a ceramic membrane 203, a top plate 204 is installed on the top of the frame 202, a feed port 205 is installed on the top of the top plate 204, the outer surface of the feed port 205 is provided with a first screw thread 206, the frame 202 The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com