Disposal method for XDK adsorbent for waste transformer oil for standardized discharge

A technology that meets emission standards and transformer oil is applied in chemical instruments and methods, transformer/inductor cooling, separation methods, etc. It can solve problems such as the difficulty of direct recycling of impurities in the crystallization mother liquor, and achieve good adsorption effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A kind of disposal method of waste transformer oil XDK adsorbent that can discharge up to standard, said method comprises the following steps:

[0024] 1) Add petroleum ether to 500 g of waste XDK adsorbent in a mass ratio of 3:1 and stir for 10 minutes, then let stand to obtain the upper layer mixed liquid I and the lower layer adsorbent after being washed with petroleum ether;

[0025] 2) Add pure water to the adsorbent cleaned by petroleum ether and stir for 10 minutes, then let it stand to obtain the upper layer mixed liquid II, and the lower layer is the adsorbent after cleaning;

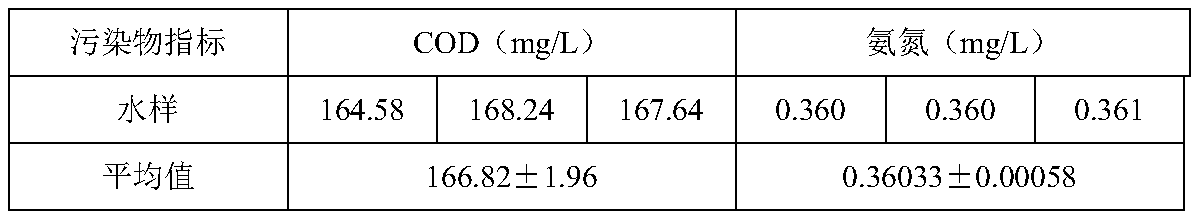

[0026] 3) Put the upper mixed liquid I and the upper mixed liquid II through the rotary evaporator body to recover petroleum ether, pour the obtained waste liquid into the oil-water separation tank for oil-water separation, and perform pollutant detection on the treated water;

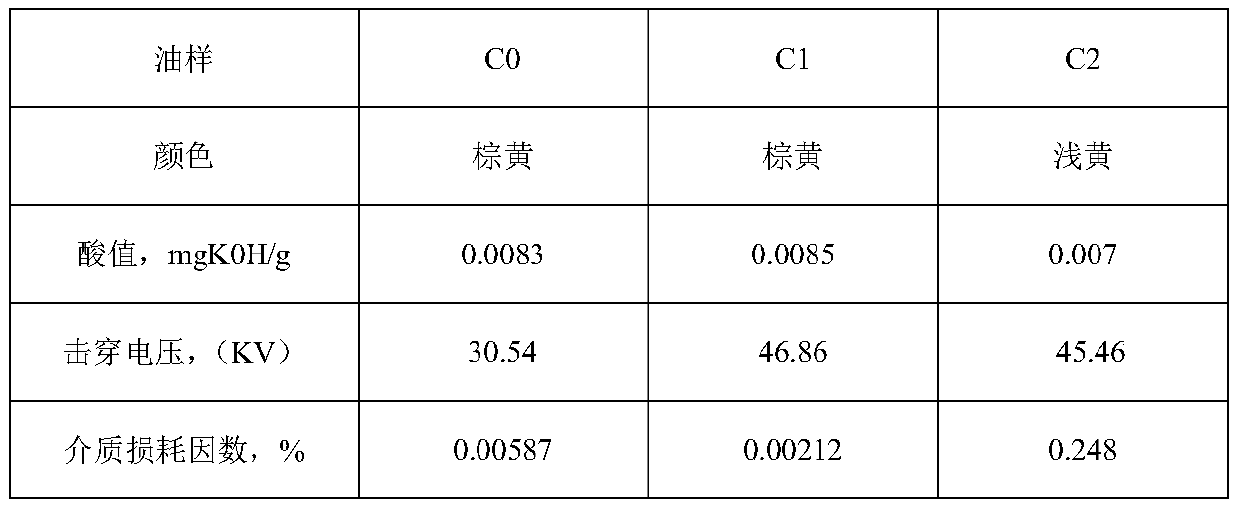

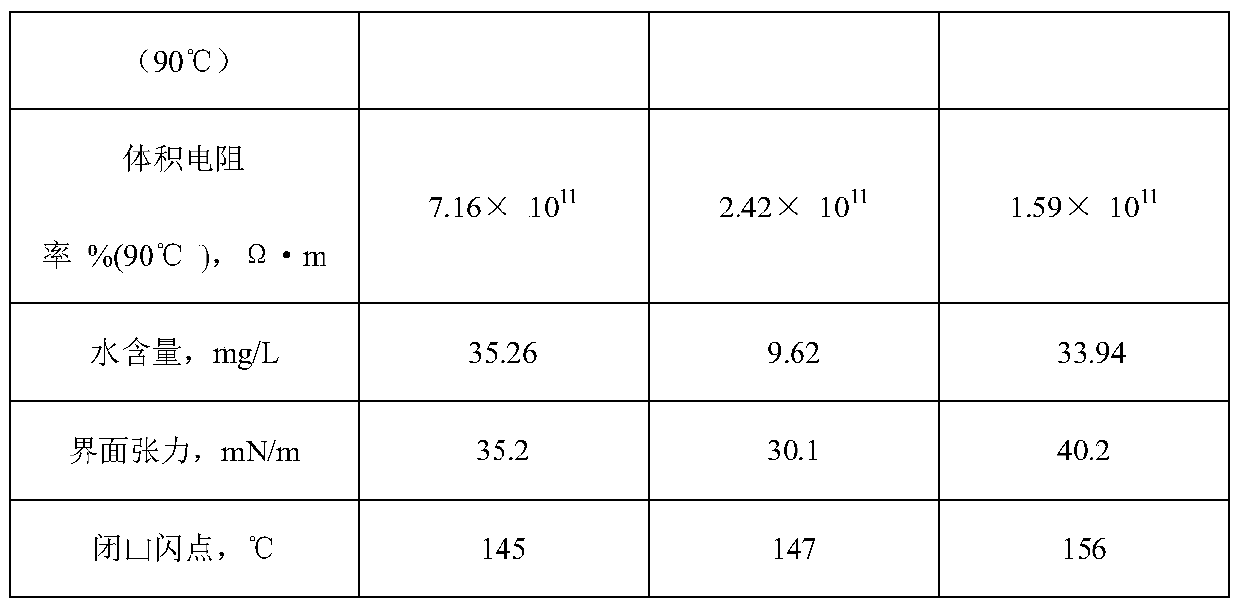

[0027] 4) Place the cleaned adsorbent in step 2) in a muffle furnace, and roast to obtain a regenerated XDK ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com