Cleaning process for medium pipeline of continuous casting equipment

A technology for equipment and medium, applied in the field of medium pipeline cleaning process of continuous casting equipment, can solve the problems of medium pipeline rust, etc., and achieve the effect of fast cleaning speed, low cost and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

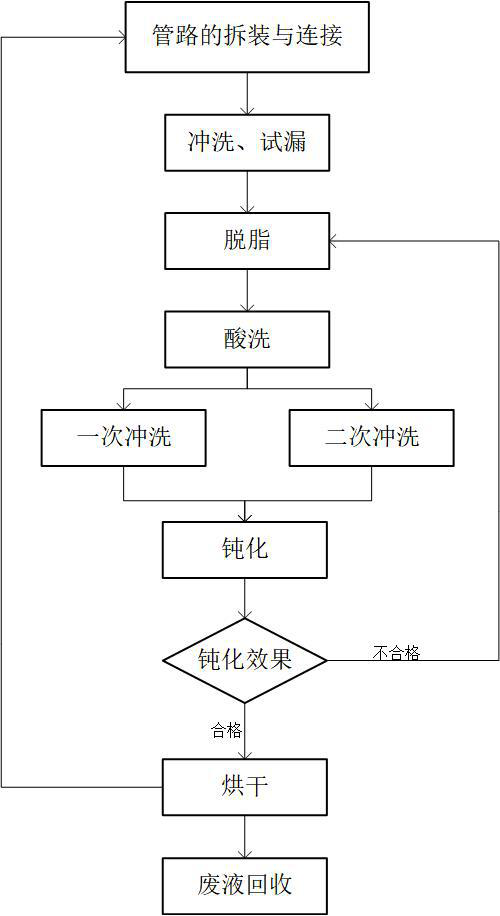

[0018] In order to explain the present invention more clearly, the pipeline cleaning process will be further described below in combination with the overall pipeline cleaning process flow and specific implementation cases.

[0019] The following are preferred implementation cases of the present invention. It should be noted that the specific conditions in the implementation cases can be determined according to actual needs and are limited to the present invention. The protection scope of the present invention shall be determined by the claims.

[0020] Take the hydraulic pipeline cleaning of slab continuous casting equipment in a steel company as an example. The material of the pipeline is stainless steel, the medium is mineral petroleum-based hydraulic oil, and the maximum size of the pipeline is Φ89*6. The pipeline is now cleaned and passivated.

[0021] Remove the original hydraulic components of the hydraulic pipeline, and connect them with hydraulic hoses to form a flushi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com