Waste heat recycling type deduster

A waste heat recovery and dust collector technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve problems such as increasing maintenance workload and maintenance costs, not exceeding 240 °C, and reducing equipment service life. The effect of reducing equipment maintenance workload, long service life and reducing land occupation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] In the following, the present invention will be specifically described through exemplary embodiments. It should be understood, however, that elements, structures and characteristics of one embodiment may be beneficially incorporated in other embodiments without further recitation.

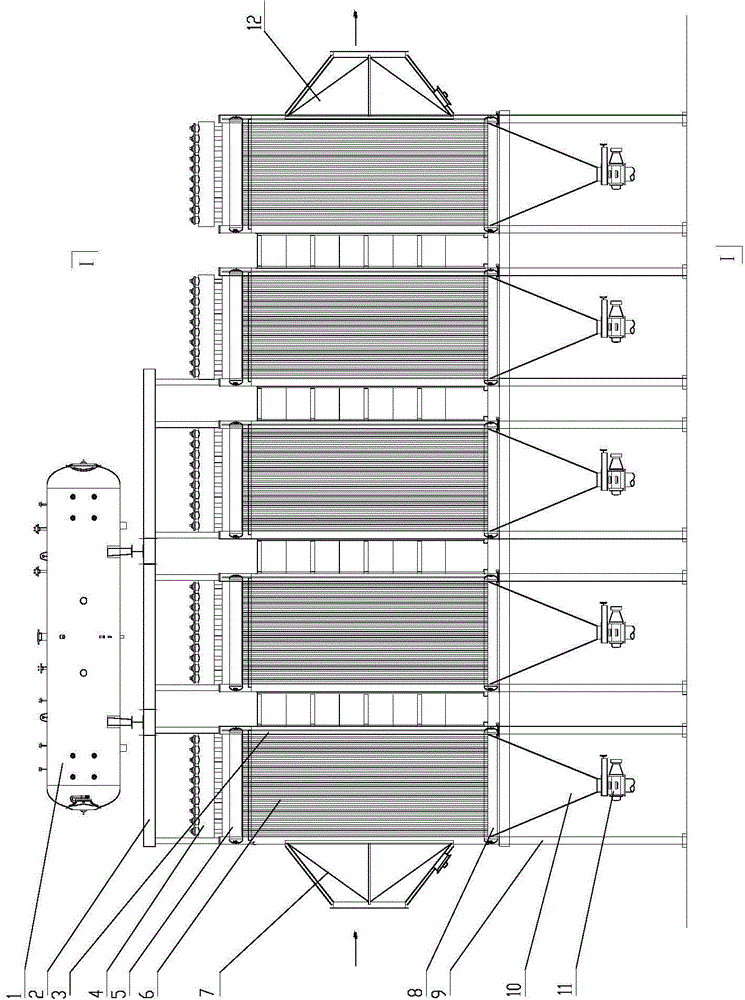

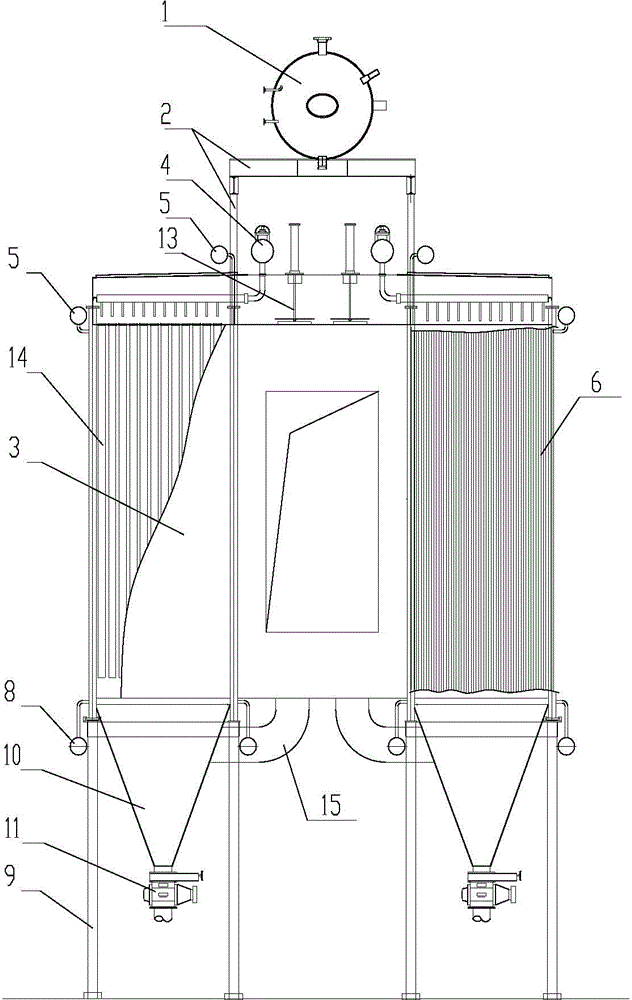

[0023] see figure 1 as well as figure 2 , as shown in the figure, the waste heat recovery dust collector of the present invention is used for waste heat recovery of high-temperature flue gas. 5 boxes 3 connected in sequence are arranged, and the inside of the box 3 forms a high-temperature flue gas circulation channel for circulating high-temperature flue gas, and a plurality of filtering devices for filtering flue gas are vertically arranged in the high-temperature flue gas circulation channel 14. The filter device 14 has high filtration accuracy, good air permeability, and high temperature resistance. The filter device 14 is preferably cylindrical, and the filter device 14 can be hung i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com