A pressurized fluidized bed boiler s-co 2 Cycle power generation system and method

A technology of S-CO2 and pressurized fluidization, which is applied in fluidized bed combustion equipment, combustion methods, fuels burned in a molten state, etc., can solve the problem of reducing the mass flow rate of working fluid, increasing the pressure drop of boiler internal parts, increasing Boiler size and other issues, to achieve the effect of reducing boiler size and high cycle efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

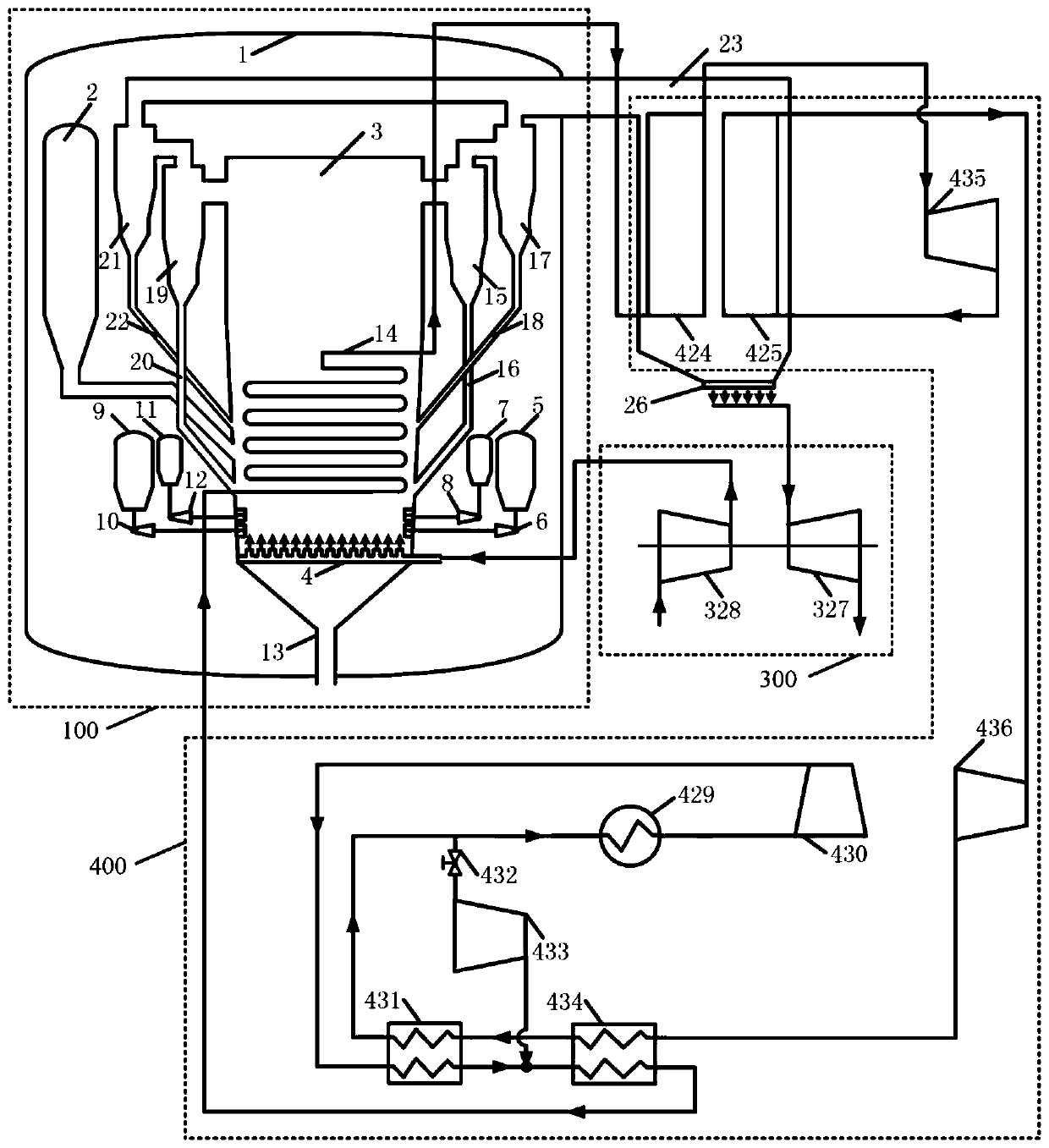

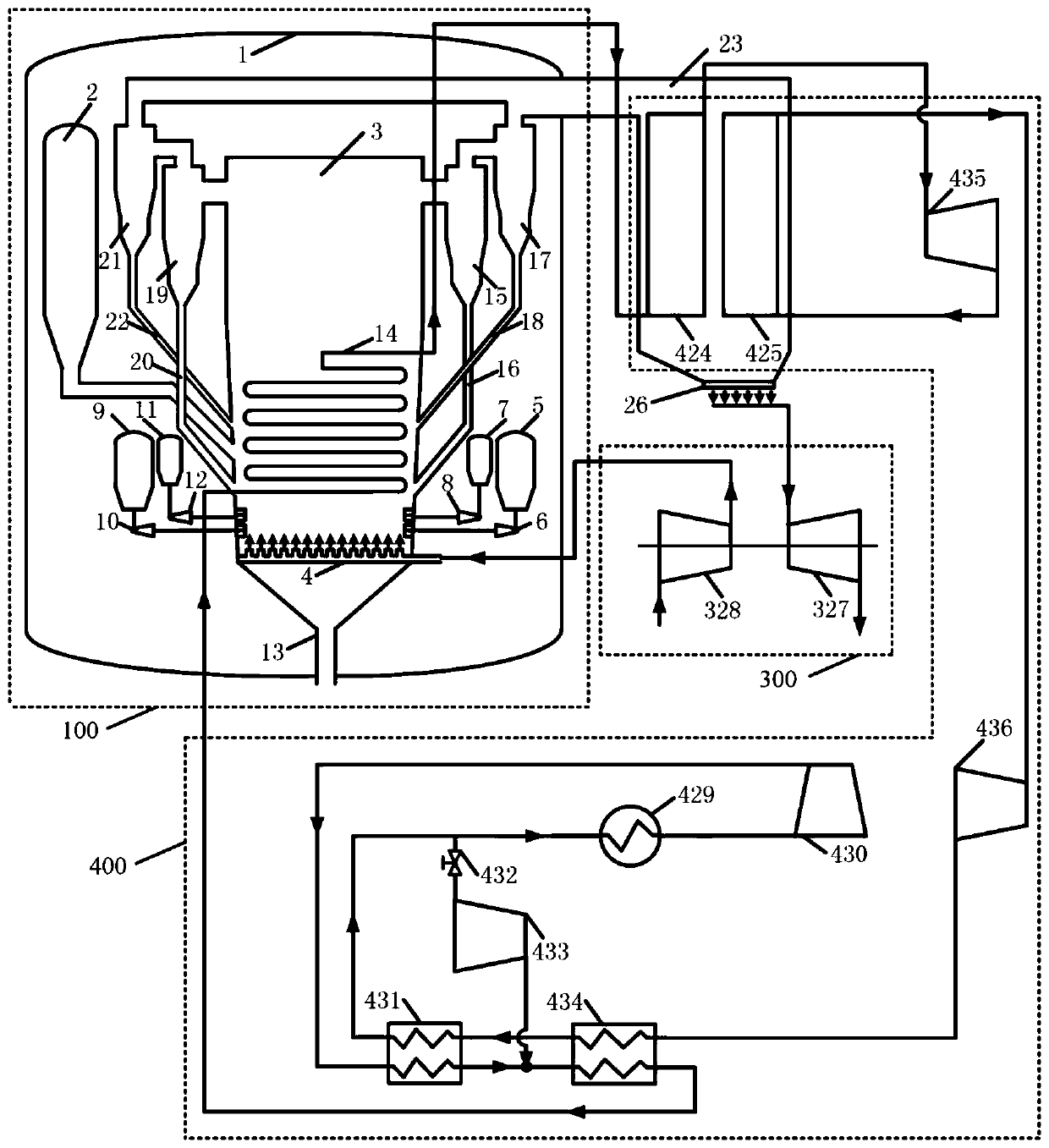

[0032] A high-efficiency heat exchange pressurized fluidized bed boiler S-CO of the present invention will be further described below in conjunction with the accompanying drawings. 2 Examples of cycle power generation systems are figure 1 As shown, it includes: tail flue 23, flue gas outlet 26, booster boiler system 100, waste heat recovery system 300, primary reheating and recompression cycle system 400, where the three systems work together to efficiently convert the heat generated by coal combustion For power; the flue gas outlet of the booster boiler system 100 is connected to the tail flue 23 and the flue gas outlet 26 in sequence, and the superheater 424 and the reheater 425 in the primary reheating and recompression cycle system 400 are installed in the tail flue 23 The waste heat recovery system 300 is arranged outside the flue gas outlet 26; the coal is first burned in the pressurized boiler system 100 to produce heat, and the high-temperature flue gas carrying heat e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com