Washing fixture and washing method

A technology for cleaning fixtures and holes, applied in cleaning methods and utensils, cleaning methods using liquids, chemical instruments and methods, etc., can solve the problems of UV glue being difficult to remove, slow cleaning speed, etc. effect of speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

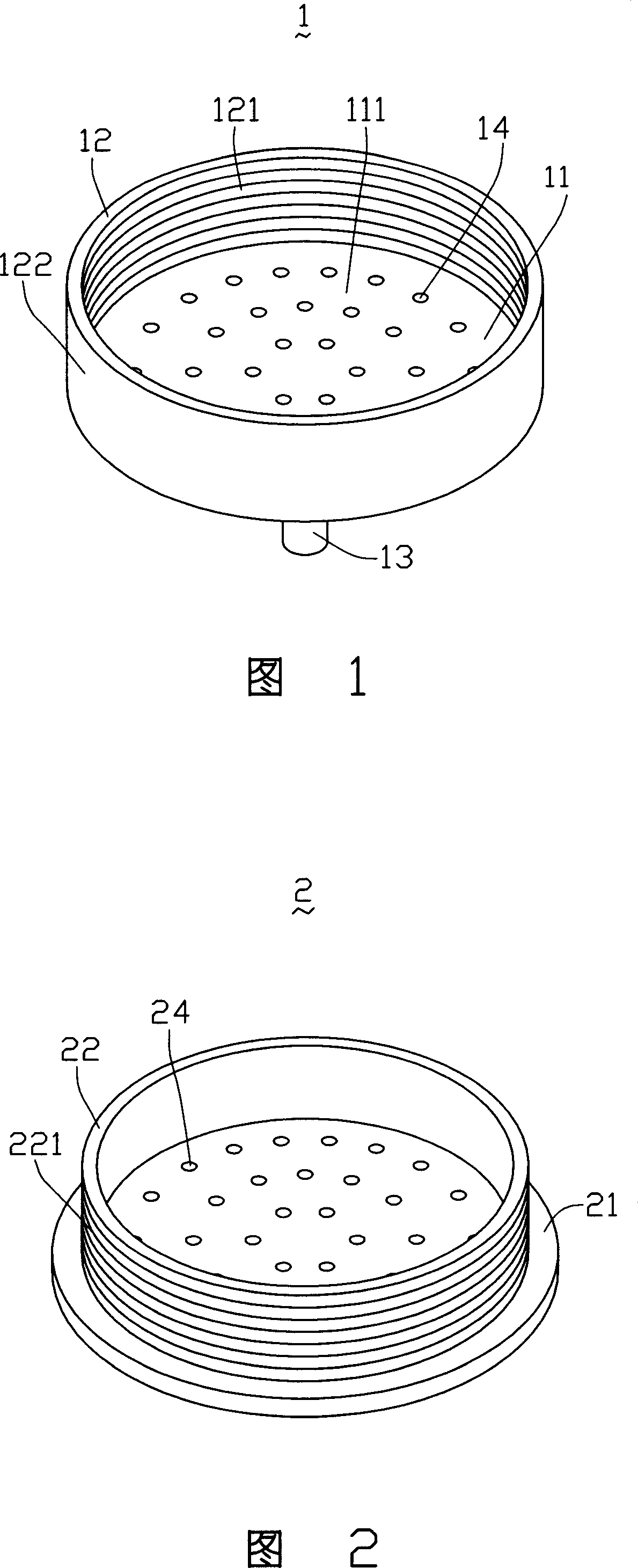

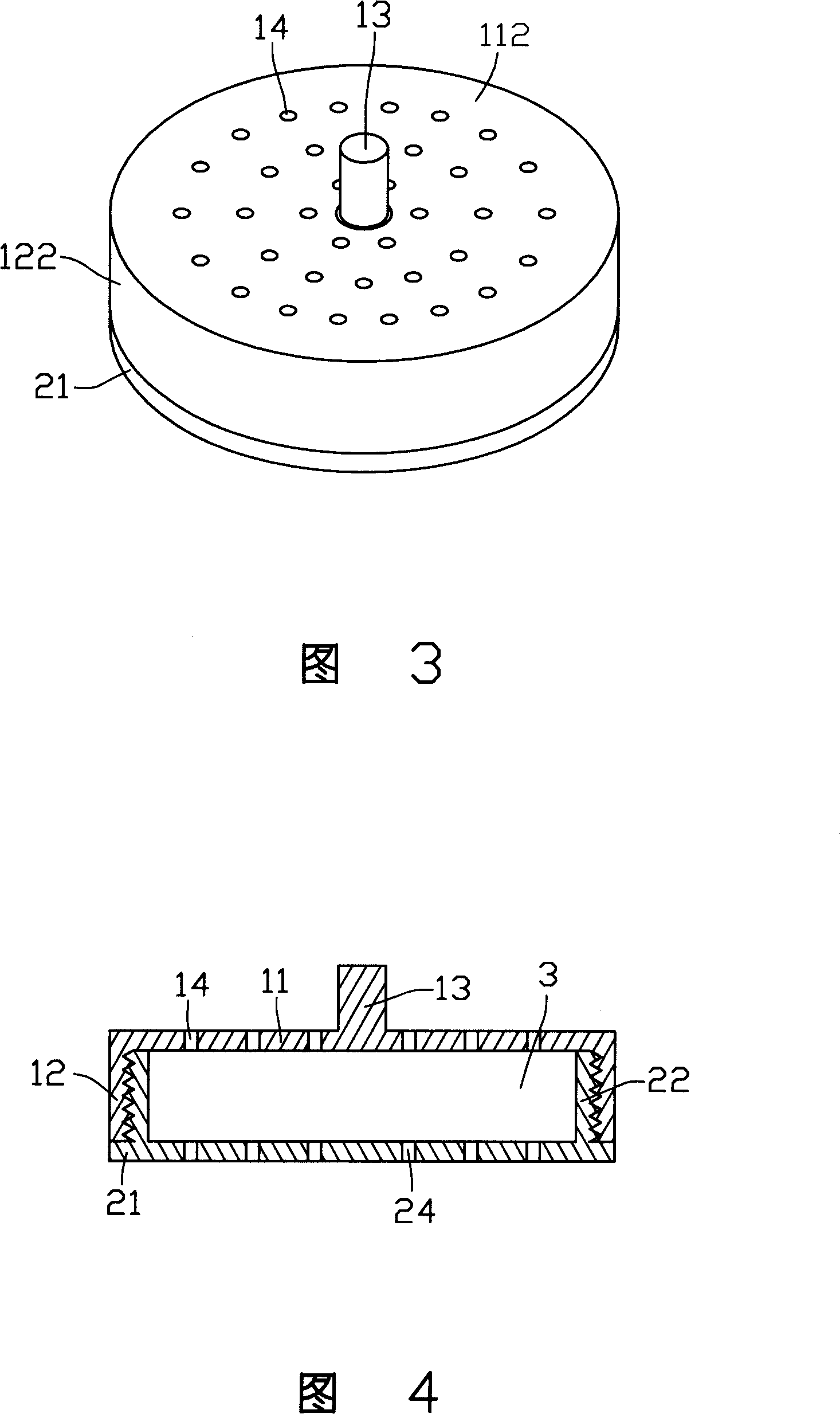

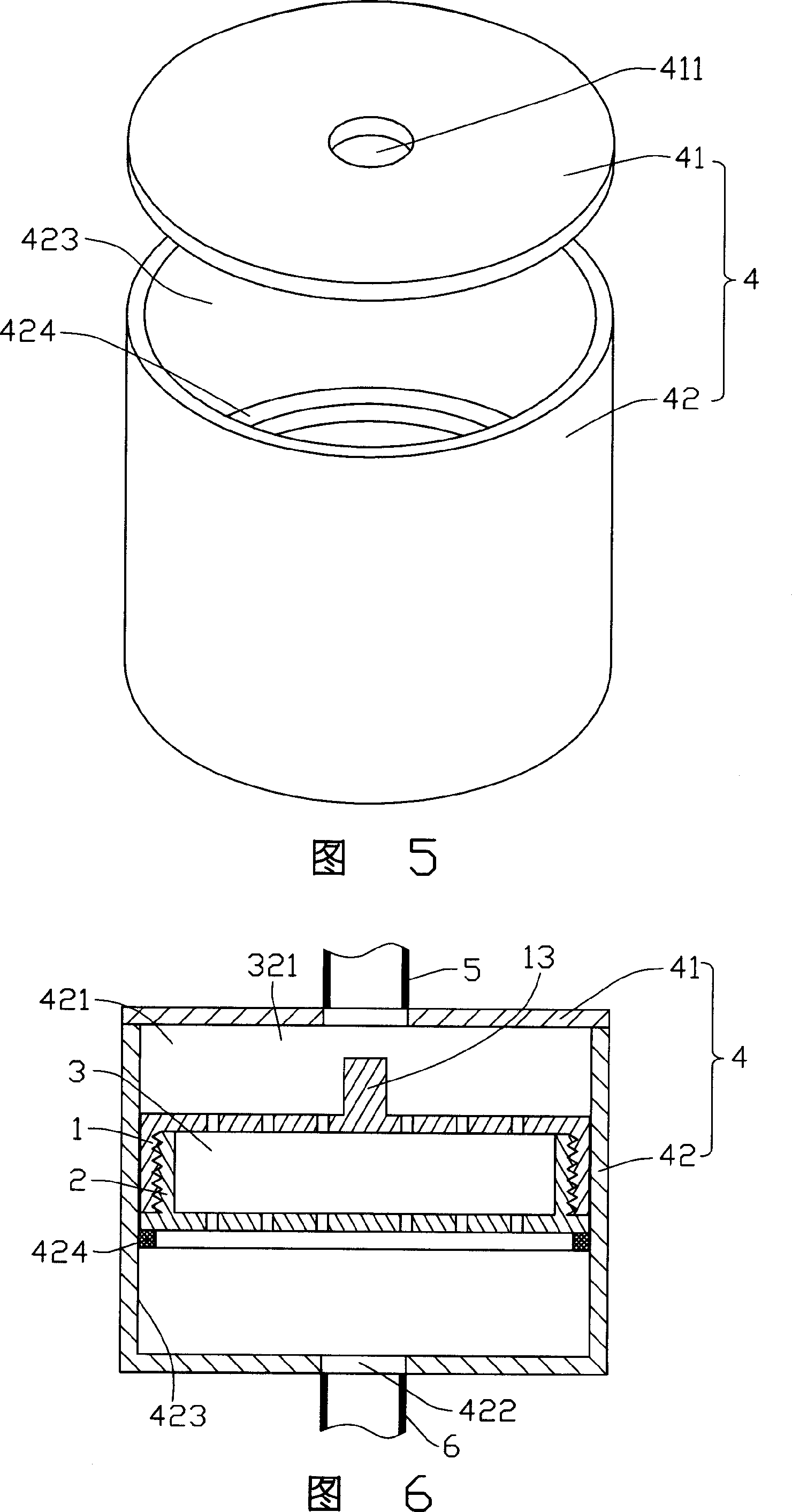

[0015] Referring to FIG. 1 , FIG. 2 , FIG. 5 and FIG. 6 , a preferred embodiment of the cleaning fixture of the present invention includes an upper cover 1 , a lower plate 2 and a housing 4 . The preferred embodiment of the cleaning fixture of the present invention cooperates with a first water pipe 5 and a second water pipe 6, and can be used to clean small-sized workpieces that are glued together and have a large number, such as optical lenses of digital cameras.

[0016] Referring to FIG. 2 and FIG. 3 , the upper cover 1 includes a circular first bottom plate 11 , a cylindrical first shell 12 , a handle 13 and a plurality of upper cleaning holes 14 . The first bottom plate 11 includes a circular inner bottom surface 111 and a circular outer bottom surface 112 , and the inner bottom surface 111 is opposite to the outer bottom surface 112 . One end of the first shell 12 is connected to the inner bottom surface 111 , and the first bottom plate 11 closes the end of the first sh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com