High-precision grinding machine for plane machining of sealing element

A technology for plane processing and seals, which is applied in the field of grinding machines, can solve problems such as unstable machining accuracy and quality, uneven depth of seal planes, unqualified seal planes, etc., to increase practical performance, simplify operation procedures, Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

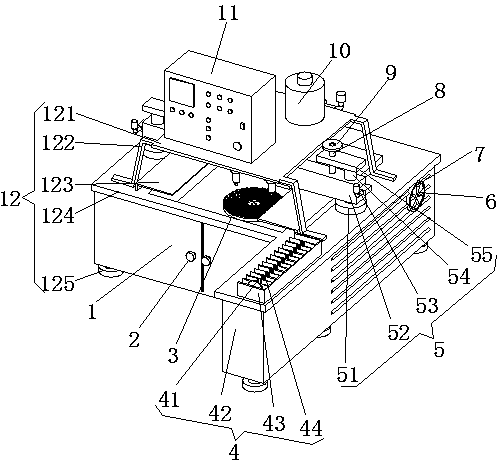

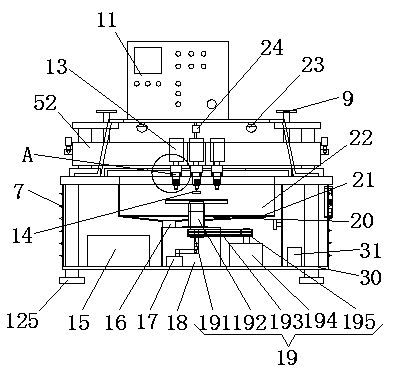

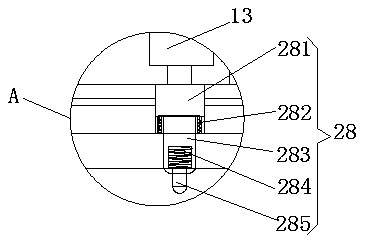

[0035] see Figure 1-5 , the present invention provides a technical solution: a high-precision grinding machine for surface processing of seals, including a tool box unit 4, an adjustment unit 5, a support unit 12, a power unit 19 and a pressing structure 28;

[0036] Support unit 12: The support unit 12 includes a bearing platform 124, the lower surface of the bearing platform 124 is provided with supporting legs 125, a bottom plate 30 is arranged between the supporting legs 125, a water tank 18 is arranged on the upper surface of the bottom plate 30, and a water pump 17 is arranged in the water tank 18 , the water pump 17 is connected to the lower end of the rotating shaft 192 through a conduit, the upper end of the water tank 18 is provided with a return pipe 16, the return pipe 16 is connected to the lower end of the water bucket 20, the upper end of the water bucket 20 is connected to the lower end of the grinding chamber 22, and the water bucket 20 is connected to the gri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com