Preparation process of nitrocellulose membrane

A technology of nitrocellulose membrane and preparation process, which is applied in the field of nitrocellulose membrane preparation, can solve problems affecting the quality of nitrocellulose membrane, achieve the effects of ensuring quality and production continuity, reducing impurities, and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

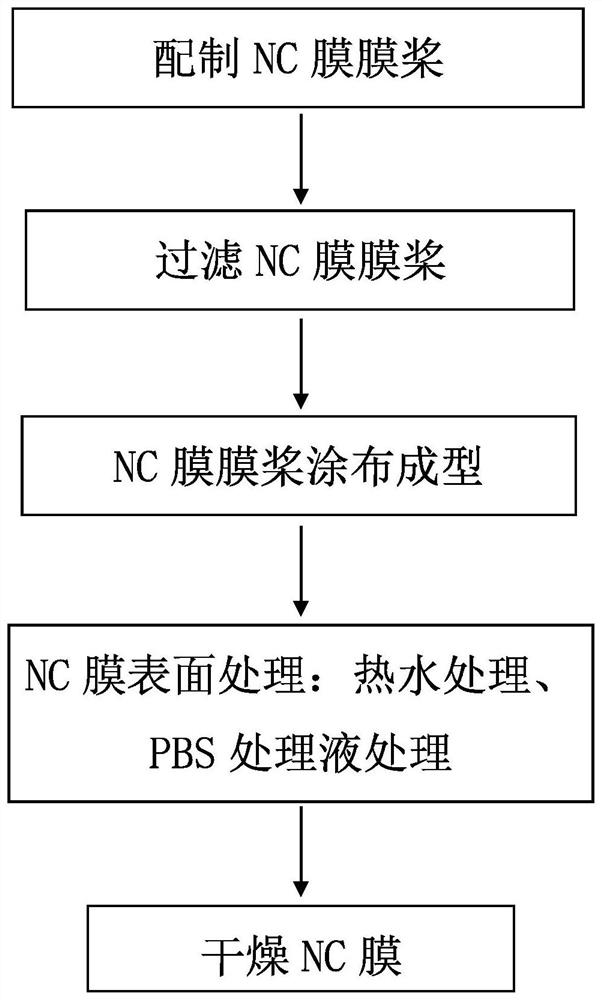

[0051] refer to figure 1 and figure 2 , the preparation process of NC film is as follows:

[0052] (1) Preparation of NC membrane paddle: Measure 100L of acetone and pour it into the liquid mixing tank, add 25kg of nitrocellulose, start the stirrer at 65r / min and stir for 3 hours, then add 45L of ethanol, 40L of n-butanol and 5L of glycerin to continue stirring. Stir for 3 days. Observe the solids in the stirred sample to complete the dissolution of the NC membrane paddle;

[0053] (2) Filtration NC membrane membrane paddle: use oil-proof polytetrafluoroethylene (PTFE) filter membrane paddle, and place it for 3 days;

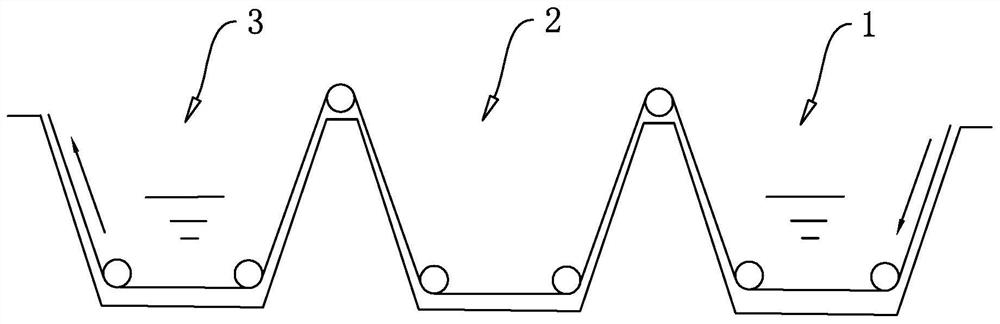

[0054] (3) NC film paddle coating molding: PE film is closely attached to the stainless steel, the NC film paddle solution is injected on the PE film, and the NC film paddle solution runs with the PE film on the stainless steel belt at a constant speed;

[0055] The membrane paddle solution of the NC membrane passes through the constant temperature box at 2...

Embodiment 2

[0061] The difference between Example 2 and Example 1 is that in step (1), measure 110L of acetone and pour it into the liquid mixing tank, add 25kg of nitrocellulose, turn on the agitator at 65r / min and stir for 3 hours, then add 40L of ethanol, 50L of n-butanol and 6L of glycerol continued to stir for 3 days. Observe the situation of the solids in the stirred sample to complete the dissolution of the membrane paddle;

[0062] In step (3), the humidity of the air is 65%;

[0063] In step (4), the water temperature of the NC membrane hot water treatment is 60°C.

Embodiment 3

[0065] The difference between Example 3 and Example 1 is that in step (1), 90L of acetone is measured and poured into the liquid mixing tank, 27kg of nitrocellulose is added, the stirrer is turned on at 65r / min and stirred for 3 hours, and then 50L of ethanol, 40L of n-butanol and 6L of glycerol continued to stir for 3 days. Observe the situation of the solids in the stirred sample to complete the dissolution of the membrane paddle;

[0066] In step (4), the water temperature of the NC membrane hot water treatment is 66°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com