Small-size cover plate washing machine and washing method thereof

A small size, cleaning machine technology, applied in the field of mechanical cleaning, can solve the problems of waste of resources, environmental pollution of industrial cleaning agents, physical hazards of workers, etc., and achieve the effect of saving water costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

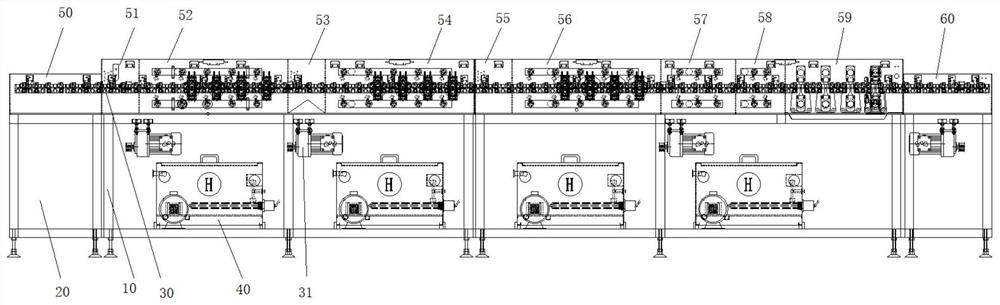

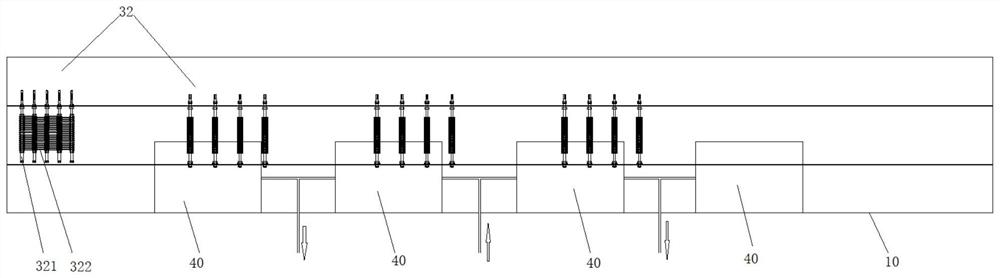

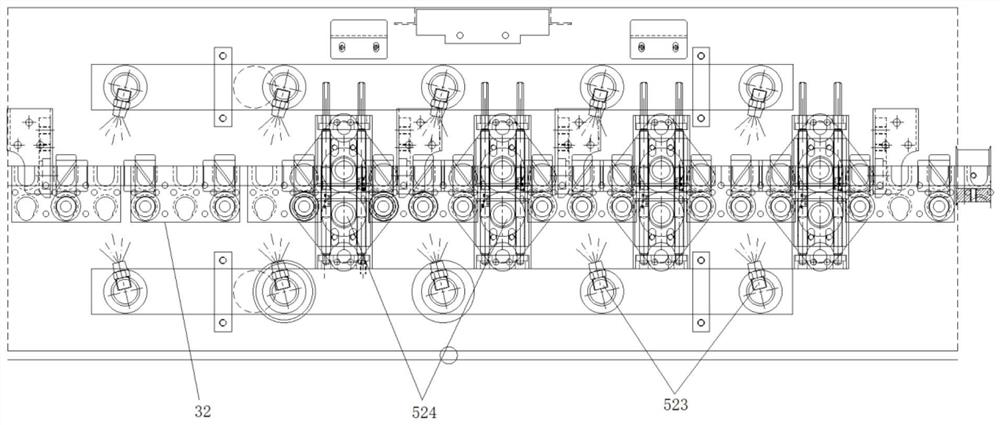

[0035] After the equipment is installed according to the structure described above, it enters the waiting state. After starting the equipment, the transmission mechanism 30 runs, and the cover plate to be cleaned is placed on the material inlet 50 . The conveying motor drives the conveying roller 32 to run, and the shaft core 321 of the conveying roller 32 rotates to drive the rubber ring 322 to move the cover plate toward the outlet 60, passing through the first wind cutting chamber 51, the first cleaning area 52, the second The wind cutting chamber 53, the second cleaning area 54, the third wind cutting chamber 55, and the third cleaning area 56 carry out three rounds of deionized water cleaning and drying with gradually increasing purity, and then pass through the fourth cleaning area 57 for higher purity. deionized water spray cleaning, the fifth cleaning zone 58 for pure water cleaning, and finally four groups of drying air knives in the fourth air cutting chamber 59 to dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com