Preparation method for coal-based vinyl acetate carrier carbon

A technology of coal-based vinyl acetate and base vinyl acetate, which is applied in the field of preparation of coal-based vinyl acetate carrier carbon, can solve the problems of low carbon wear resistance, low acetic acid adsorption, large catalyst consumption, and difficult activation, and reduce external overburning Phenomenon, shortening of activation reaction time, effect of reducing difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

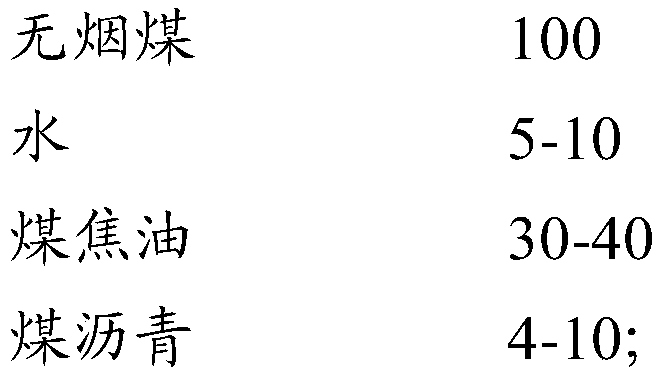

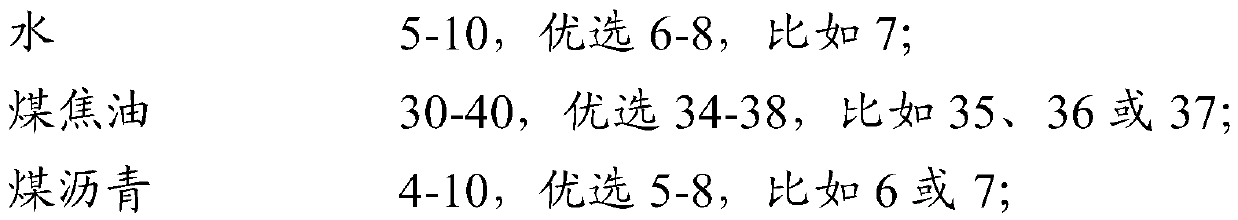

[0062] The Taixi anthracite with an ash content of less than 3wt% is ground to D90<75μm, and the Taixi anthracite, water, coal tar and coal pitch are kneaded uniformly in a twin-shaft agitating kneader at a weight ratio of 100:6:33:6 to form coal paste , and then extruded into charcoal strips on a hydraulic molding machine; the charcoal strips were dried and solidified, and then entered a carbonization furnace for carbonization at 650 ° C; the obtained carbonized material was sent to an activation furnace, and high-temperature steam was introduced to conduct an activation at 910 ° C. 15min, get the primary activation material, then cool the primary activation material to 30 ℃, then re-send it into the activation furnace, and pass high-temperature steam, carry out secondary activation at 950 ℃, the secondary activation time is 25min, get Secondary activation material; the obtained secondary activation material is soaked for 5h with hydrochloric acid having a concentration of 5wt...

Embodiment 2

[0064] Compared with Example 1, there are only the following differences:

[0065] The weight ratio of Taixi anthracite, water, coal tar and coal pitch is 100:6:33:10.

[0066] The obtained coal-based vinyl acetate carrier carbon is denoted as product B, the ash content of product B is 5.1wt%, the adsorption capacity of acetic acid is 535mg / g, the adsorption capacity of zinc acetate is 5.29g / 100ml, and the strength is 95wt%.

Embodiment 3

[0068] Compared with Example 1, there are only the following differences:

[0069] The primary activation time is 20min, and the secondary activation time is 30min.

[0070] The obtained coal-based vinyl acetate carrier carbon is denoted as product C, the ash content of product C is 5.1wt%, the adsorption capacity of acetic acid is 548mg / g, the adsorption capacity of zinc acetate is 5.39g / 100ml, and the strength is 94wt%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com