Dyeing process for improving turquoise blue leveling property of wool

A blue and wool technology, applied in the field of wool dyeing, can solve the problems of poor solubility and diffusion permeability, low diffusion performance, low one-time success rate, etc. color flower effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

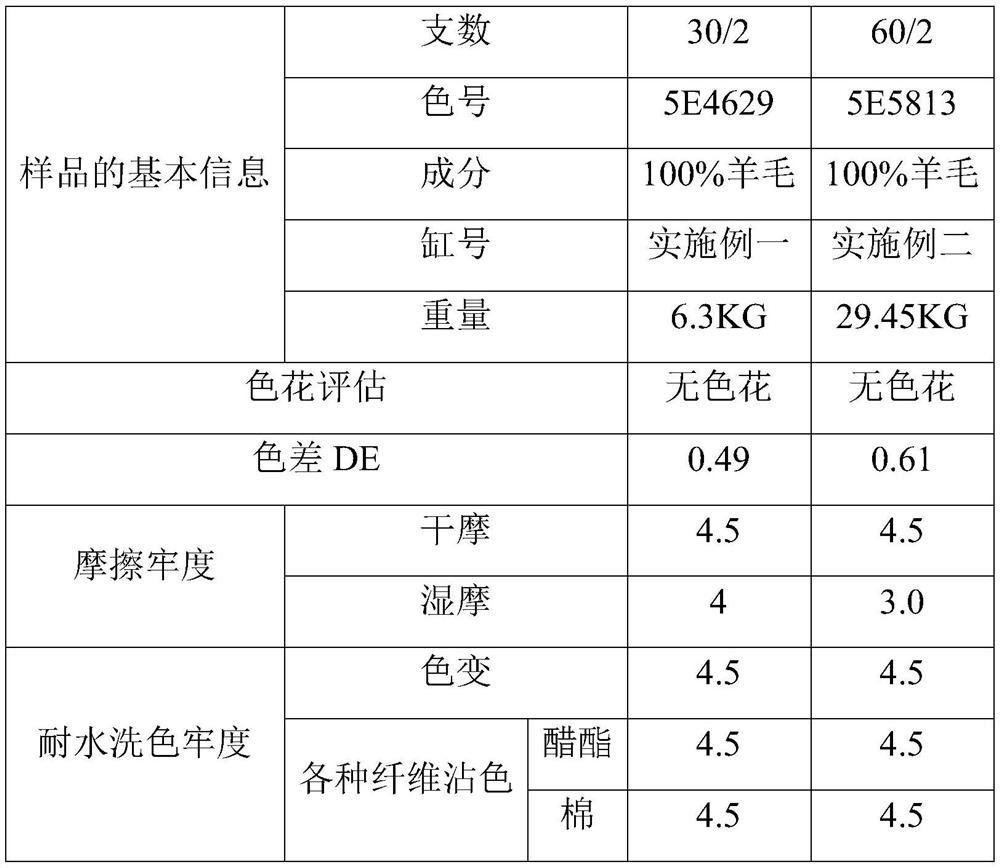

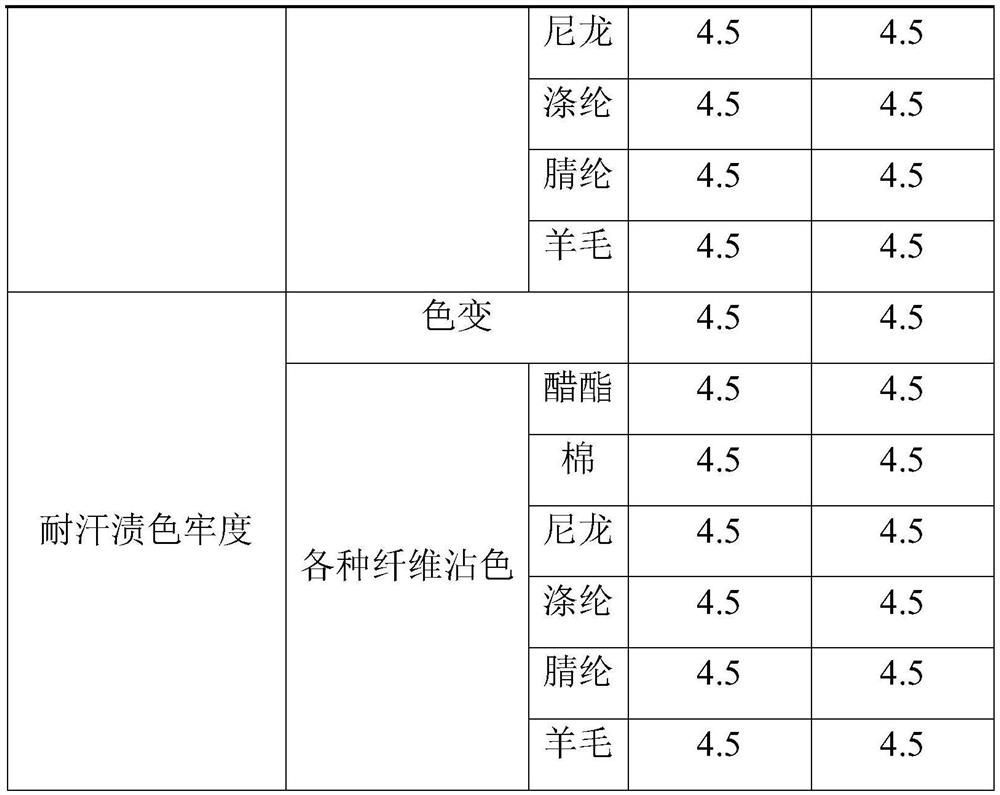

Embodiment 1

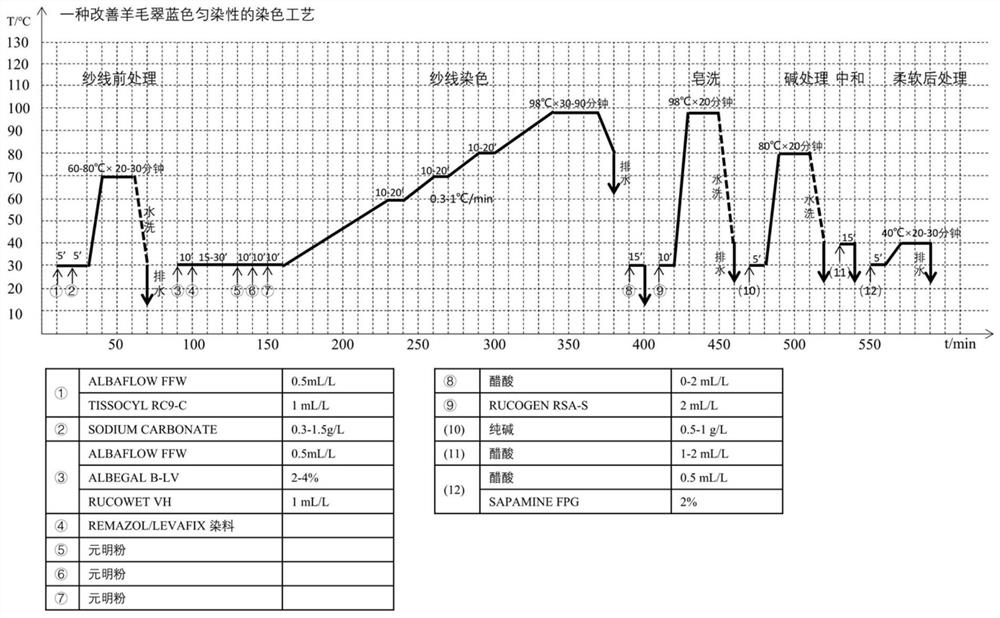

[0040] A kind of dyeing process of present embodiment improves the level dyeing property of emerald blue of wool, comprises the following steps:

[0041] 1) Yarn pretreatment, add osmotic defoamer and degreasing agent at room temperature, run for 5 minutes, then add soda ash, run for 5 minutes, then raise the temperature to 80°C and keep it warm for 20 minutes, then wash with overflow water for 15 minutes, drain , wherein the osmotic defoamer is ALBAFLOW FFW, and its consumption is 0.5mL / L; the degreasing agent is TISSOCYL RC9-C, and its consumption is 1mL / L; the soda ash consumption is 0.3g / L;

[0042] 2) Yarn dyeing, add osmotic defoamer, leveling agent, exhaust defoamer penetrant at room temperature, run for 10 minutes, add dye linearly and quantitatively for another 30 minutes, and then use the ratio of 30% / 30% / 40% Add the sodium sulfate in three times, run for 10 minutes after each addition, then raise the temperature to 60℃ at 0.5°C / min and keep it for 20 minutes, then r...

Embodiment 2

[0046] A kind of dyeing process of present embodiment improves the level dyeing property of emerald blue of wool, comprises the following steps:

[0047] 1) Yarn pretreatment, add osmotic defoamer and degreaser at room temperature, run for 5 minutes, then add soda ash, run for 5 minutes, then raise the temperature to 70°C and keep it warm for 20 minutes, then wash with overflow water for 15 minutes, drain ; Wherein the osmotic defoamer is ALBAFLOW FFW, and its consumption is 0.5mL / L; the degreasing agent is TISSOCYL RC9-C, and its consumption is 1mL / L; the soda ash consumption is 0.5g / L;

[0048] 2) Yarn dyeing, add osmotic defoamer, leveling agent, exhaust defoaming penetrant at room temperature, run for 10 minutes, add dye linearly and quantitatively for another 15 minutes, and then use the ratio of 30% / 30% / 40% Add the sodium sulfate in three times, run for 10 minutes after each addition, then raise the temperature to 60°C at 0.7°C / min and keep it for 15 minutes, then raise ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com