Wool fiber biotechnology processing equipment

A biotechnology, wool fiber technology, applied in the field of wool fiber biotechnology processing equipment, can solve the problems of uneven worker level, complexity, and consumption of transportation resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described in detail below in conjunction with the accompanying drawings, so that those skilled in the art can implement it with reference to the description.

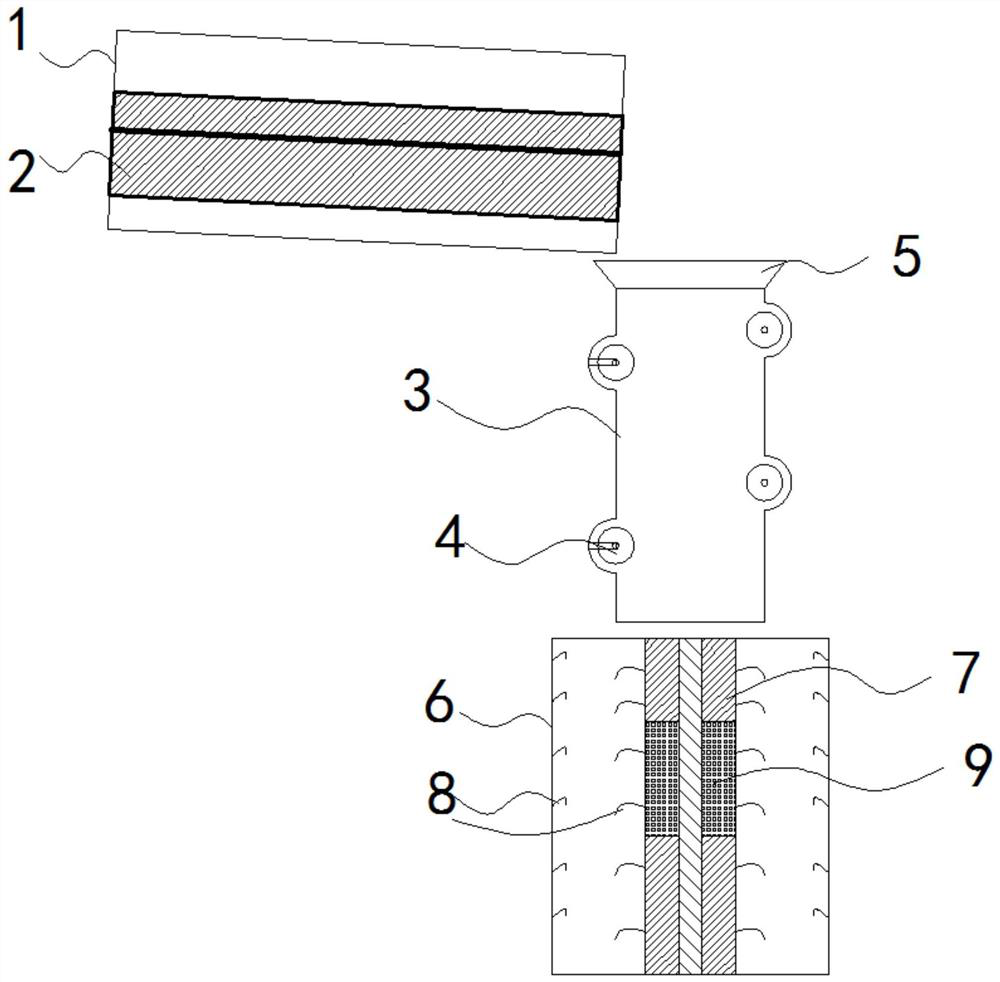

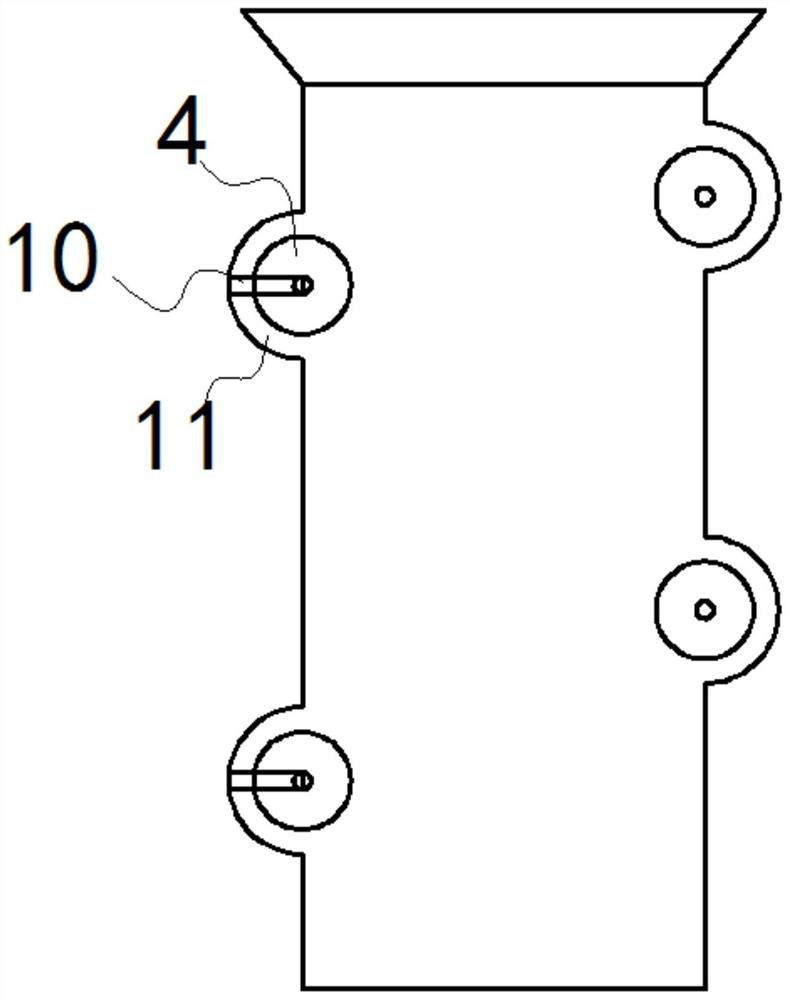

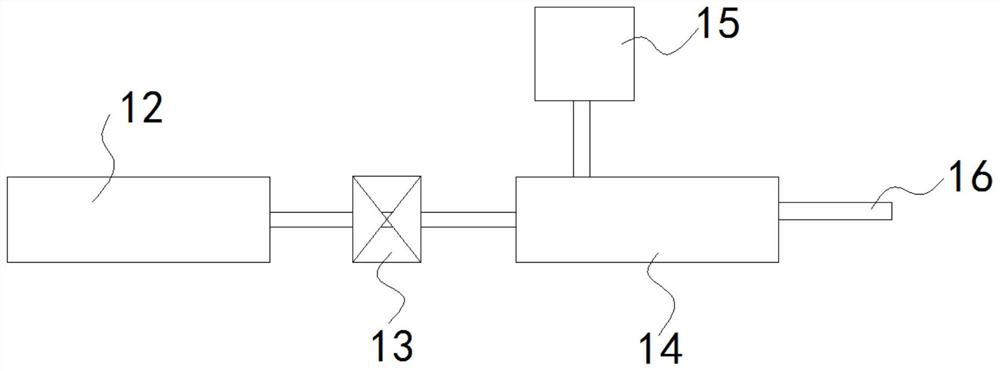

[0029] Such as figure 1 , 2 , 3, 4 and 5, a wool fiber biotechnology treatment equipment, comprising:

[0030]Cleaning device, which includes the first cylinder 1 inclined at 5-10°, the first cylinder 1 is inclined to make the wool slowly move from the first high section to the low end under the action of its own gravity, and at the same time facilitate water from the low One end is automatically discharged; and the eccentric roller 2 concentrically arranged in the first roller 1, the eccentric roller can form the wool in the rolling space to be evenly squeezed, and the wool is rolled on the eccentric roller 2 and the first roller after rolling. 1 between the rolling space to facilitate cleaning; and the activated carbon injection unit arranged in the eccentric roller, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com