800 MPa level hot-rolled threaded steel bar and production method

A technology of threaded steel bars and production methods, applied in the field of iron and steel metallurgy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] The chemical composition of the 800MPa grade hot-rolled rebar in this example is: C 0.18wt%, Si 0.85wt%, Mn1.30wt%, Nb 0.02wt%, Ti 0.05wt%, Mo 0.12wt%, Cr 0.59wt%, B 0.009wt% %, Cu0.03wt%, the rest is Fe and unavoidable impurities, Ceq=0.54.

[0046] Converter smelting, LF refining, continuous casting into 150mm×150mm billet; the temperature of the soaking section of the billet in the heating furnace is 1150-1200°C, and the total heating time is 70min; after that, the continuous rod rolling machine is used for rolling. The manufacturing specification is Ф22mm, the starting rolling temperature is 1020-1050°C, the temperature of the upper cooling bed is 680-730°C, and the 800MPa grade threaded steel bar is obtained by natural cooling to room temperature. The structure of the prepared steel bar is bainite and ferrite, and the proportion of the bainite structure is 81%.

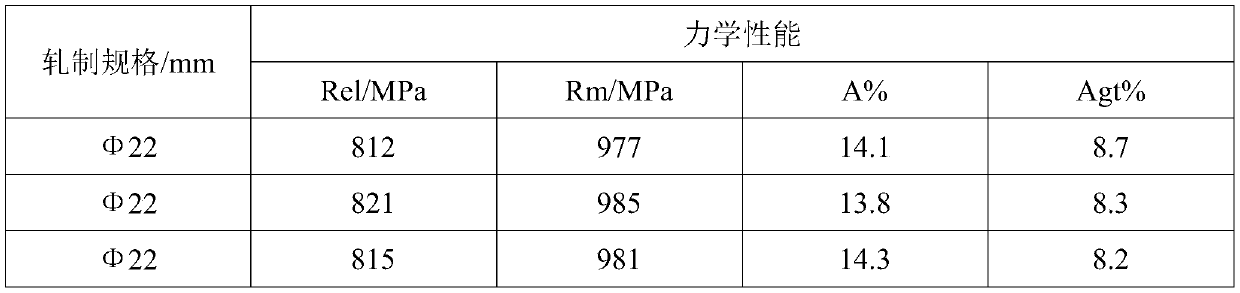

[0047] Table 1 shows the mechanical properties of steel bars, yield strength > 800MPa, tensile strengt...

Embodiment 2

[0051] The chemical composition of the 800MPa grade hot-rolled rebar in this example is: C 0.17wt%, Si 1.17wt%, Mn1.71wt%, Nb 0.03wt%, Ti 0.02wt%, Mo 0.11wt%, Cr 0.41wt%, B 0.003wt% %, Cu0.05wt%, the rest is Fe and unavoidable impurities, Ceq=0.56.

[0052] Converter smelting, LF refining, continuous casting into 150mm×150mm billet; the temperature of the soaking section of the billet in the heating furnace is 1200-1250°C, and the total heating time is 80min; after that, the continuous rod rolling machine is used for rolling. The manufacturing specification is Φ22mm, the starting rolling temperature is 1050-1080°C, the temperature of the upper cooling bed is 750-780°C, and the 800MPa grade threaded steel bar can be obtained by natural cooling to room temperature. The prepared steel structure is bainite and ferrite, and the proportion of bainite is 85%.

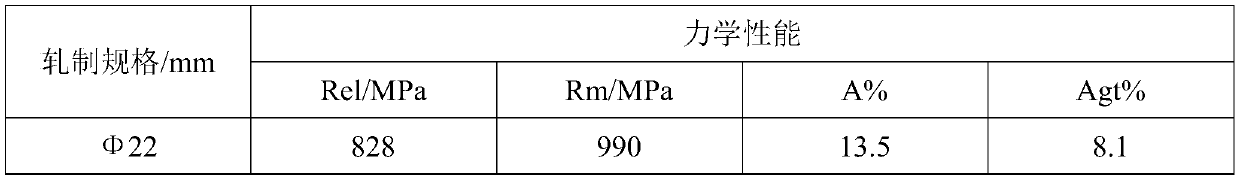

[0053] Table 2 shows the mechanical properties of steel bars, yield strength > 800MPa, tensile strength > 960MPa, elongatio...

Embodiment 3

[0058] The chemical composition of the 800MPa grade hot-rolled rebar in this example is: C 0.16wt%, Si 0.32wt%, Mn1.01wt%, Nb 0.01wt%, Ti 0.12wt%, Mo 0.31wt%, Cr 0.87wt%, B 0.002wt% %, Cu0.07wt%, the rest is Fe and unavoidable impurities, Ceq=0.57.

[0059] Converter smelting, LF refining, continuous casting into 150mm×150mm billet; the temperature of the soaking section of the billet in the heating furnace is 1180-1230°C, and the total heating time is 70min; after that, the continuous rod rolling machine is used for rolling. The manufacturing specification is Φ22mm, the starting rolling temperature is 1060-1090°C, the temperature of the upper cooling bed is 720-750°C, and the 800MPa grade threaded steel bar can be obtained by natural cooling to room temperature. The prepared steel structure is bainite and ferrite, and the proportion of bainite is 83%.

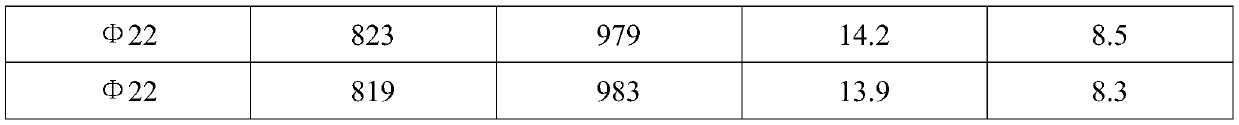

[0060] Table 3 shows the mechanical properties of steel bars, yield strength > 800MPa, tensile strength > 960MPa, elongatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com