Method for preparing anorthite toughened ceramic by utilizing desulfurized gypsum

A technology of desulfurized gypsum and toughened ceramics, which is applied in the field of preparing anorthite toughened ceramics by using desulfurized gypsum, which can solve the problems of product toughness to be improved, high energy consumption for firing, and scarcity of high-quality raw materials, so as to save resource consumption and reduce liquid phase The effect of forming temperature and improving physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

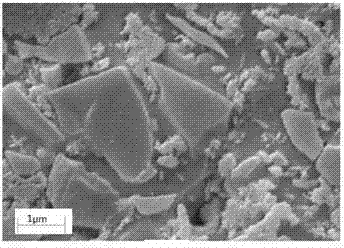

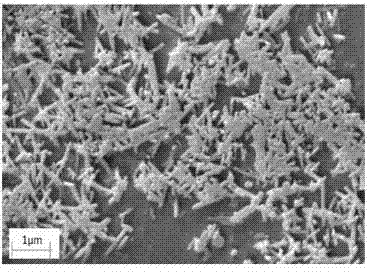

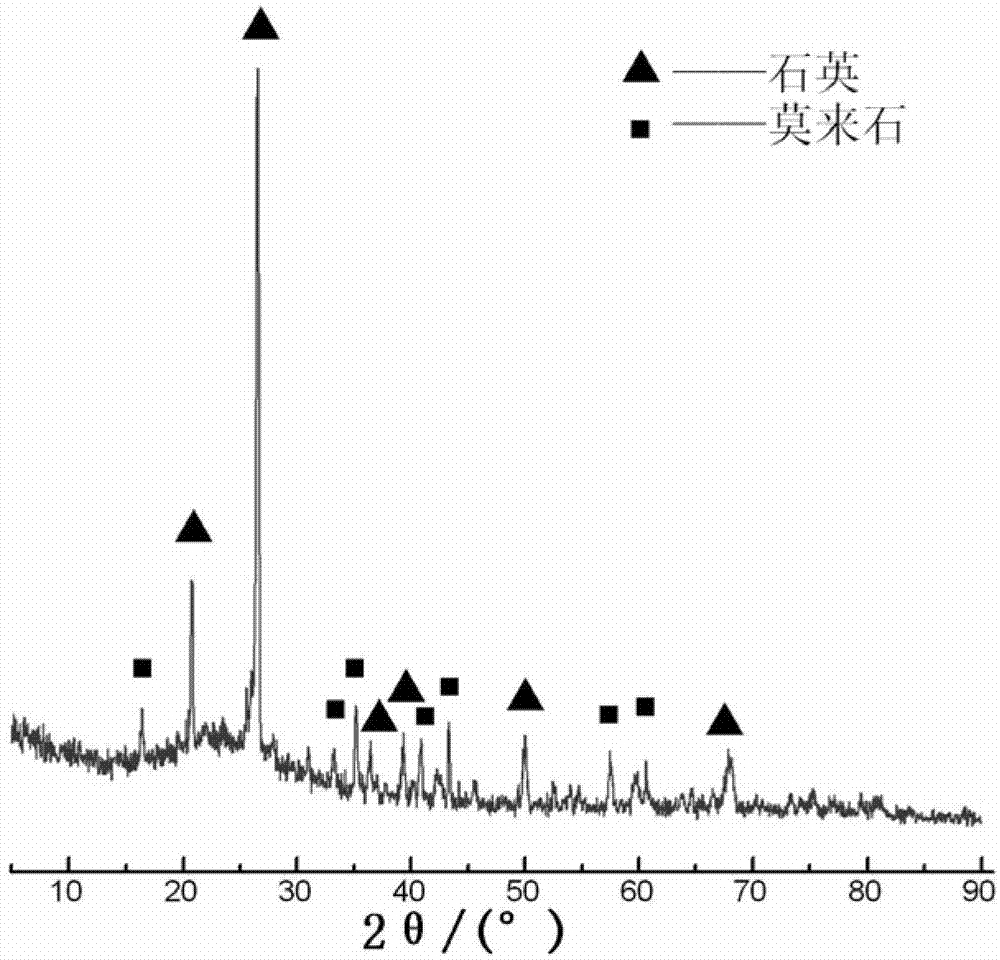

Image

Examples

Embodiment 1

[0025] A method for preparing anorthite toughened ceramics by utilizing desulfurized gypsum:

[0026] (1) In terms of weight percentage, mix 30% of desulfurized gypsum and 70% of ceramic blank (chemical composition as shown in Table 1), and wet ball mill to mix the raw materials evenly; desulfurized gypsum is calcium sulfate type flue gas desulfurization waste residue, the main component is calcium sulfate , residual limestone and calcium oxide, wherein the weight content of calcium sulfate is 60%;

[0027] (2) Grinding and drying the slurry in step (1), and dry pressing to obtain a ceramic green body;

[0028] (3) The ceramic green body is fired in a kiln, the firing temperature is controlled at 1180°C, and the high temperature holding time is 90 minutes to prepare ceramic samples.

[0029] Table 1. Chemical composition of ceramic blanks (wt%)

[0030] components

SiO 2

Al 2 o 3

K 2 o

Na 2 o

Fe 2 o 3

MgO

CaO

loss

...

Embodiment 2

[0037] A method for preparing anorthite toughened ceramics by utilizing desulfurized gypsum:

[0038](1) In terms of percentage, mix 20% of desulfurized gypsum and 80% of ceramic blank (chemical composition as shown in Table 2), and wet-mill to mix the raw materials evenly; the desulfurized gypsum is calcium sulfate-type flue gas desulfurization waste residue, the main component Calcium sulfate, residual limestone and calcium oxide, wherein the weight content of calcium sulfate is 82%;

[0039] (2) Grinding and drying the slurry in step (1), and dry pressing to obtain a ceramic green body;

[0040] (3) The ceramic green body is fired in a kiln, the firing temperature is controlled at 1200°C, and the high temperature holding time is 50 minutes to prepare ceramic samples.

[0041] Table 2 Chemical composition of ceramic blanks (wt%)

[0042] components

[0043] In Table 2, the firing temperature of the billet in the original ceramic factory is 1280°C. According to th...

Embodiment 3

[0045] A method for preparing anorthite toughened ceramics by utilizing desulfurized gypsum:

[0046] (1) In terms of weight percentage, mix 10% of desulfurized gypsum and 90% of ceramic blank (chemical composition as shown in Table 3), and wet-mill to mix the raw materials evenly; the desulfurized gypsum is calcium sulfate-type flue gas desulfurization waste residue, mainly The composition is calcium sulfate, residual limestone and calcium oxide, wherein the weight content of calcium sulfate is 75%;

[0047] (2) Grinding and drying the slurry in step (1), and dry pressing to obtain a ceramic green body;

[0048] (3) The ceramic green body is fired in a kiln, the firing temperature is controlled at 1220°C, and the high temperature holding time is 30 minutes to prepare ceramic samples.

[0049] Table 3 Chemical composition of ceramic blanks (wt%)

[0050] components

[0051] In Table 3, the firing temperature of the blank in the original ceramic factory is 1300°C. A...

PUM

| Property | Measurement | Unit |

|---|---|---|

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com