Preparation method of MAX-phase coating

A M-A-X, coating technology, applied in the field of preparation of MAX phase coatings, can solve problems such as microstructure and mechanical property damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0018] The invention provides a preparation method of a MAX phase coating. The preparation method comprises the following steps:

[0019] S1, providing a base;

[0020] S2, using the cathodic arc ion plating method in combination with the magnetron sputtering method to deposit an M-A-X coating on the surface of the substrate, wherein the cathodic arc target provides an M source, and M in the M source is a transition group metal element, and the magnetron sputtering target provides A source, A in the A source is an Al element or a Si element, the reaction gas provides an X source, and X in the X source is a C element or an N element; and

[0021] S3, annealing the substrate deposited with the M-A-X coating to obtain a MAX phase coating.

[0022] Since the above-mentioned A source is Al element or Si element, if the A source is provided by the cathodic arc target, the structure of the A-rich coating is particularly loose, especially when the A source is Al element; moreover, i...

Embodiment 1

[0040] (1) Put the cleaned and dried zirconium alloy substrate into the vacuum chamber.

[0041] (2) Introduce 100 standard ml / min of argon gas into the vacuum chamber, set the linear anode ion source current to 0.2A, and the substrate bias voltage to -300V, and use ionized argon ions to etch the substrate for 40 minutes.

[0042] (3) The Ti transition layer was deposited by arc ion plating technology, the current of the arc target was 60A, the flow rate of argon gas was 200 standard ml / min, and the deposition thickness was 350nm.

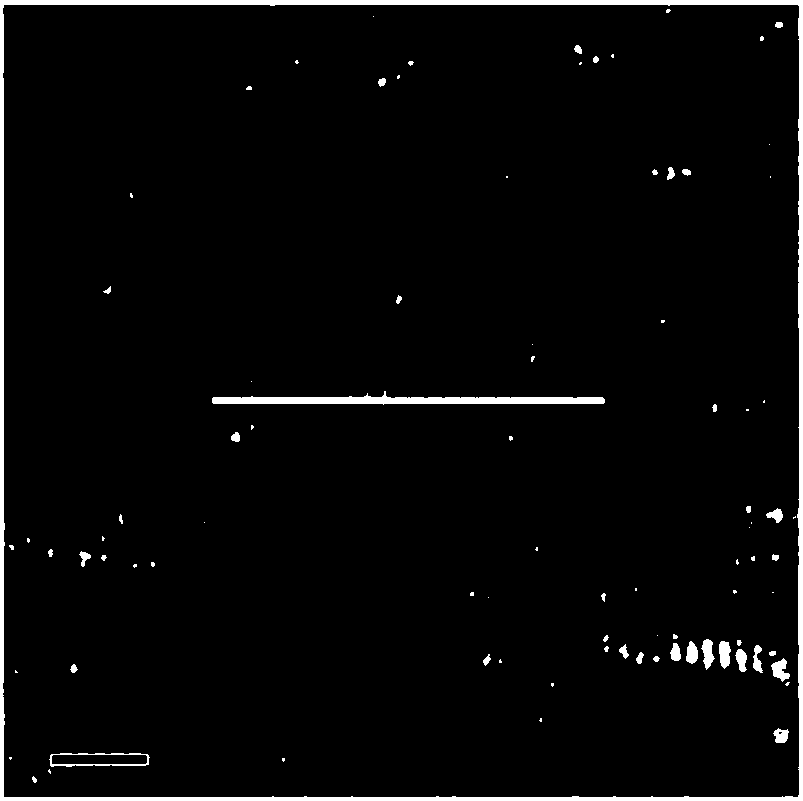

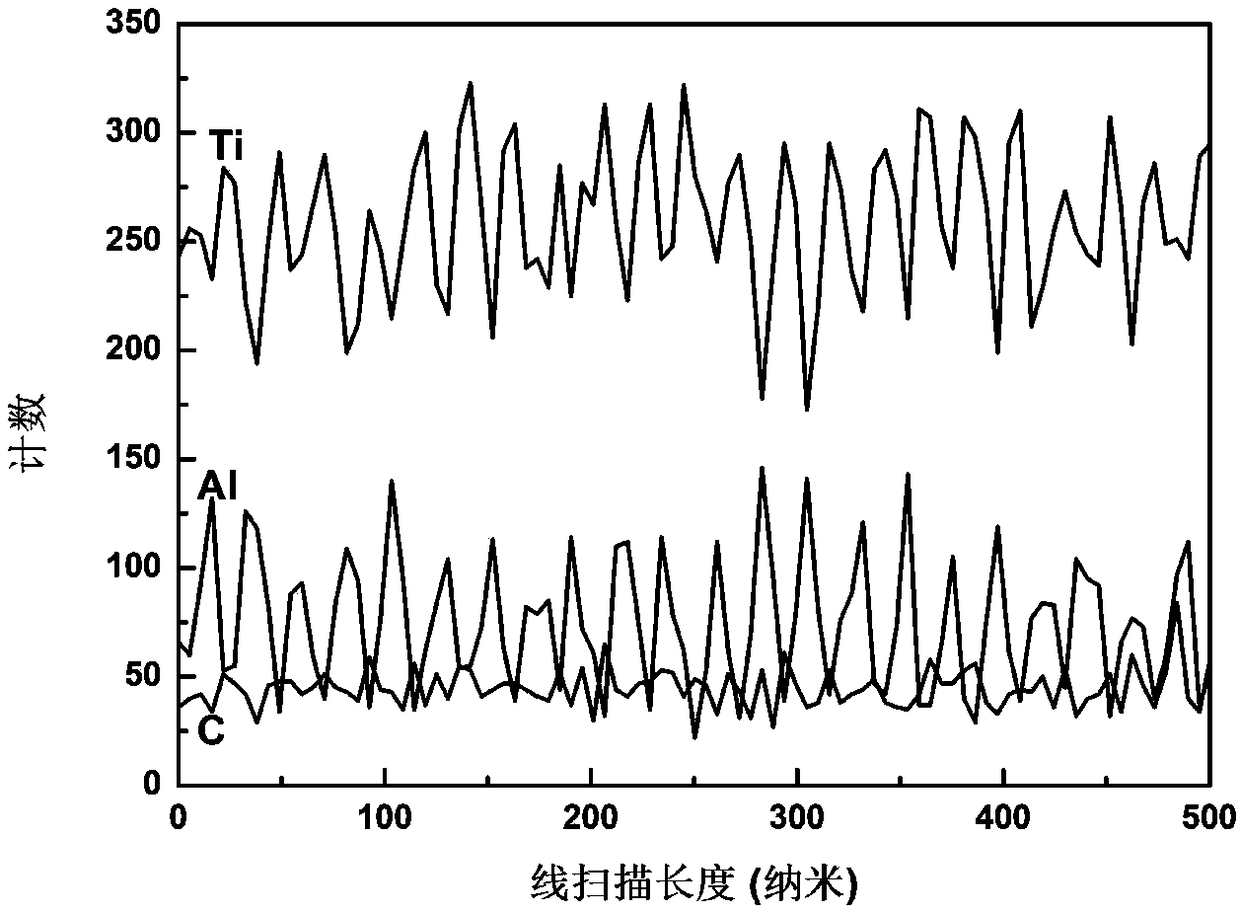

[0043] (4) The Ti-Al-C coating is deposited on the surface of the Ti transition layer by using the cathodic arc ion plating method in combination with the magnetron sputtering method, wherein the cathodic arc target provides the Ti source, the magnetron sputtering target provides the Al source, and the reaction gas CH 4 C source is provided. The substrate is periodically placed in front of the cathodic arc target and the magnetron sputtering targ...

Embodiment 2

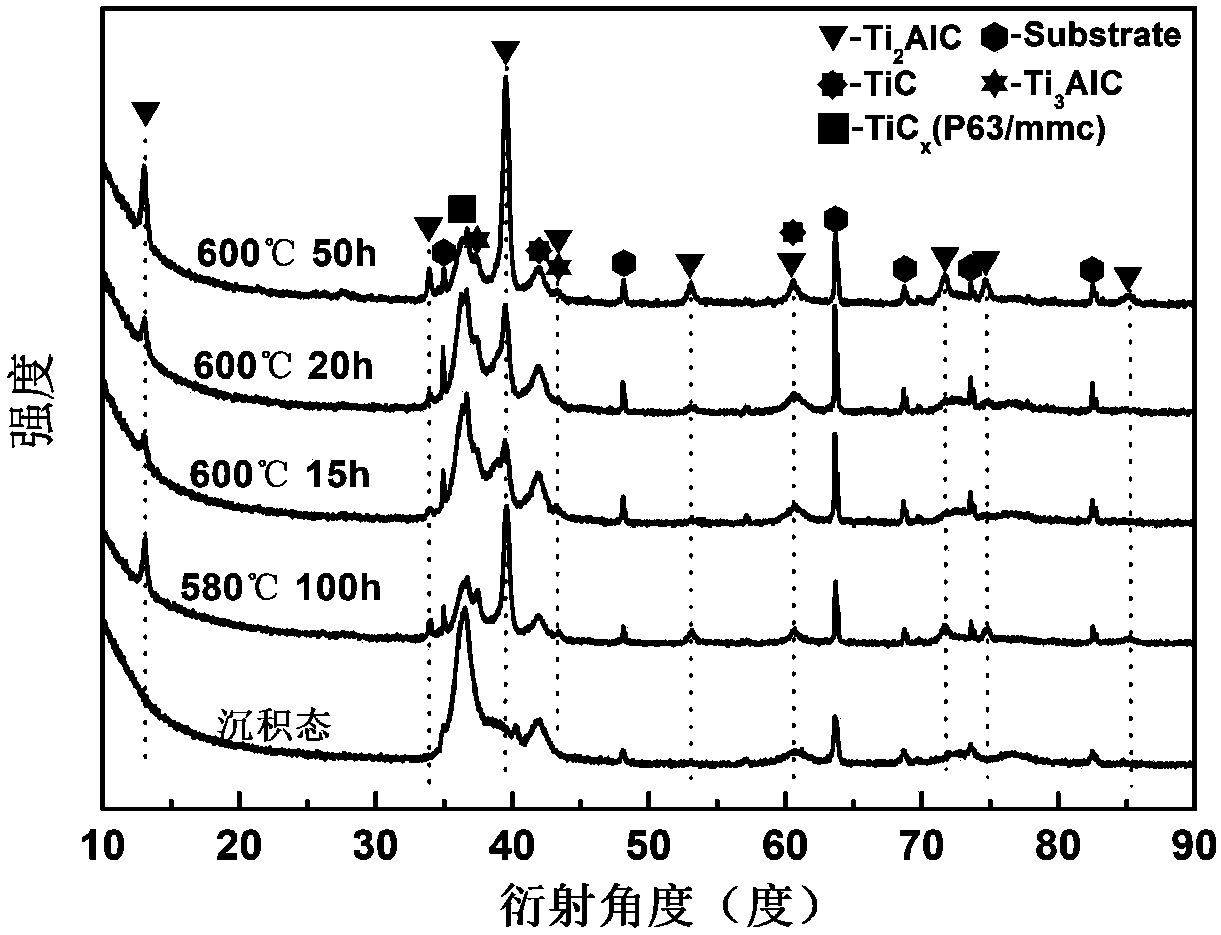

[0048] The only difference between Example 2 and Example 1 is that the annealing temperature of Example 2 is 600° C., and the holding time is 20 h. The X-ray diffraction spectrum of the coating after annealing is as follows image 3 As shown, Ti with better crystallinity was obtained 2 The MAX phase coating of AlC has a thickness of about 9 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com