Preparation method of yttrium aluminum garnet (YAG): Ce<3+> fluorescent powder using chlorides as fluxing agents

A technology of flux and phosphor, applied in the direction of chemical instruments and methods, luminescent materials, etc., to achieve the effect of improved light conversion efficiency and narrow morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

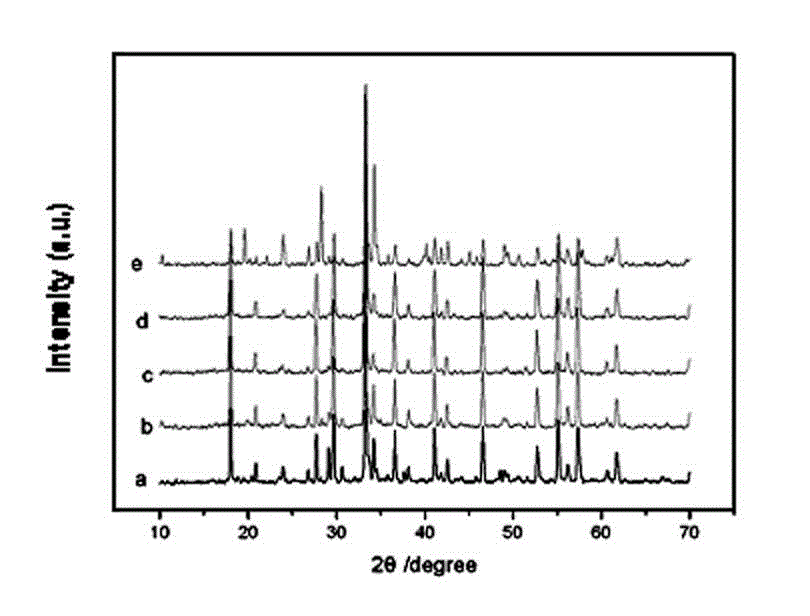

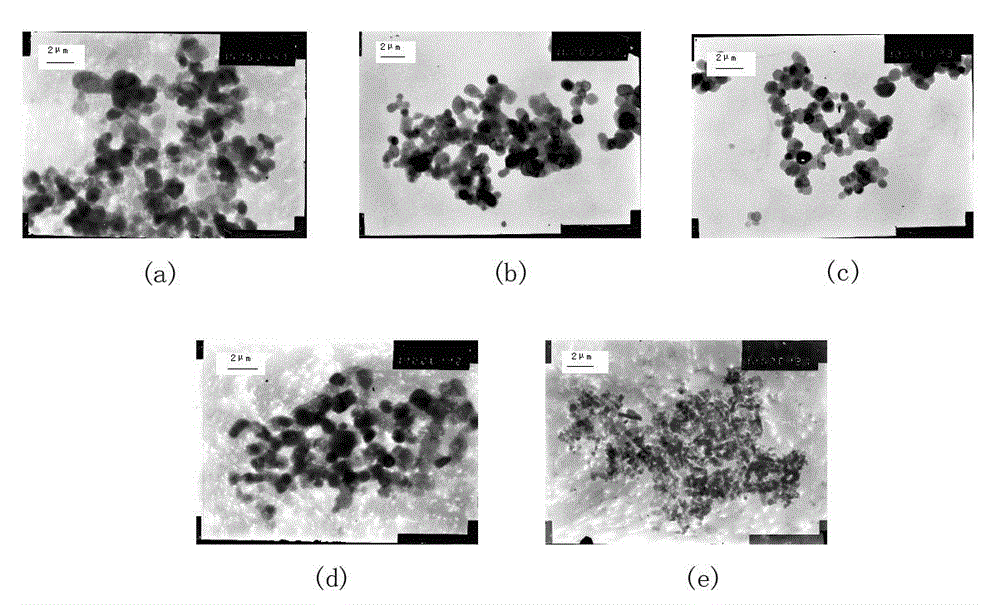

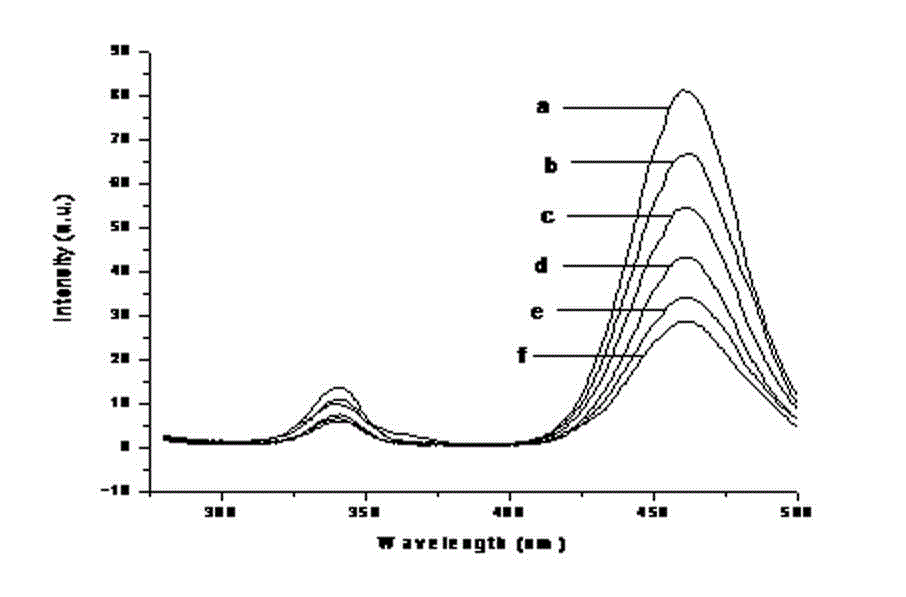

[0023] According to phosphor composition (Y 0.98 ) 3 Al 5 o 12 : Ce 0.06 Weigh the stoichiometric Y 2 o 3 (99.99%), CeO 2 (99.99%), Al 2 o 3 (AR) and fluxing agent LiCl accounting for 4% of the total weight of the phosphor composition, put the stoichiometric mixture containing the fluxing agent into an agate mortar, add an appropriate amount of absolute ethanol to make the sample just submerged, and grind for 1 hour until fully mixed; then the mixture is transferred to a small corundum crucible of 5ml, and the small corundum crucible is placed in a 30ml corundum crucible equipped with activated carbon for calcination. ~1350°C, the calcination time is 2 hours; the obtained sample is washed twice with dilute nitric acid, and then washed twice with deionized water; finally, the sample is dried in a 90°C drying oven for 3 hours. The obtained phosphor light conversion efficiency is 2.2.

Embodiment 2

[0025] According to phosphor composition (Y 0.98 ) 3 Al 5 o 12 : Ce 0.06 Weigh the stoichiometric Y 2 o 3 (99.99%), CeO 2 (99.99%), Al 2 o 3 (AR) and fluxing agent NaCl accounting for 4% of the total weight of the phosphor composition, put the stoichiometric mixture containing the fluxing agent into an agate mortar, add an appropriate amount of absolute ethanol to make the sample just submerged, and grind for 1 hour until fully mixed; then the mixture is transferred to a small corundum crucible of 5ml, and the small corundum crucible is placed in a 30ml corundum crucible equipped with activated carbon for calcination. ~1350°C, the calcination time is 2 hours; the obtained sample is washed twice with dilute nitric acid, and then washed twice with deionized water; finally, the sample is dried in a 90°C drying oven for 3 hours. The obtained phosphor has a light conversion efficiency of 2.8.

Embodiment 3

[0027] According to phosphor composition (Y 0.98 ) 3 Al 5 o 12 : Ce 0.06 Weigh the stoichiometric Y 2 o 3 (99.99%), CeO 2 (99.99%), Al 2 o 3 (AR) and fluxing agent KCl accounting for 4% of the total weight of the phosphor composition, put the stoichiometric mixture containing the fluxing agent into an agate mortar, add an appropriate amount of absolute ethanol to make the sample just submerged, and grind for 1 hour until fully mixed; then the mixture is transferred to a small corundum crucible of 5ml, and the small corundum crucible is placed in a 30ml corundum crucible equipped with activated carbon for calcination. ~1350°C, the calcination time is 2 hours; the obtained sample is washed twice with dilute nitric acid, and then washed twice with deionized water; finally, the sample is dried in a 90°C drying oven for 3 hours. The obtained phosphor has a light conversion efficiency of 2.7.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com