Method for preparing dual-perovskite type methyl hydride combustion catalyst containing titanium

A double-perovskite, methane combustion technology, applied in fuel, gas fuel, petroleum industry, etc., can solve the rare earth double-layer perovskite oxide rare and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

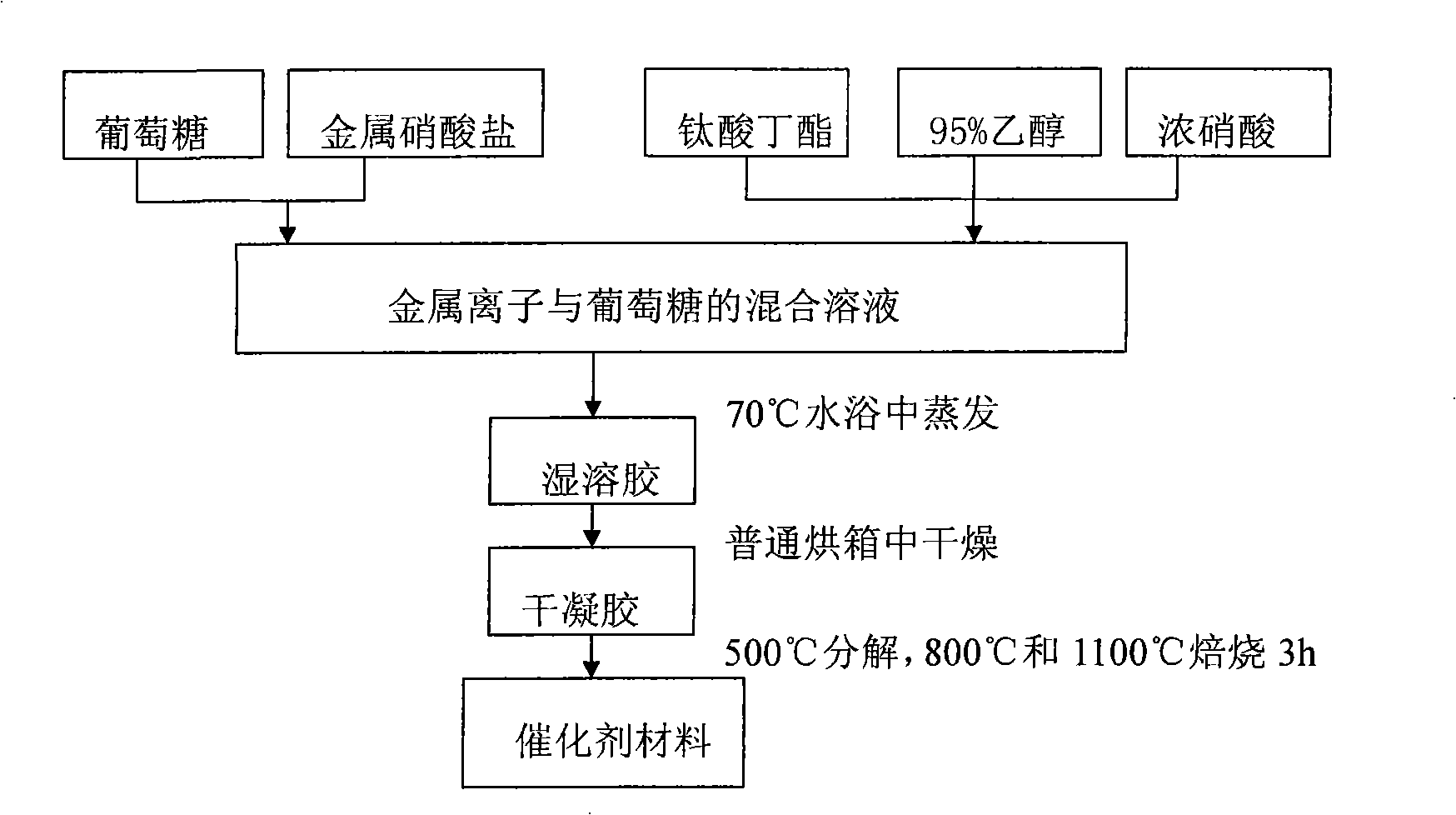

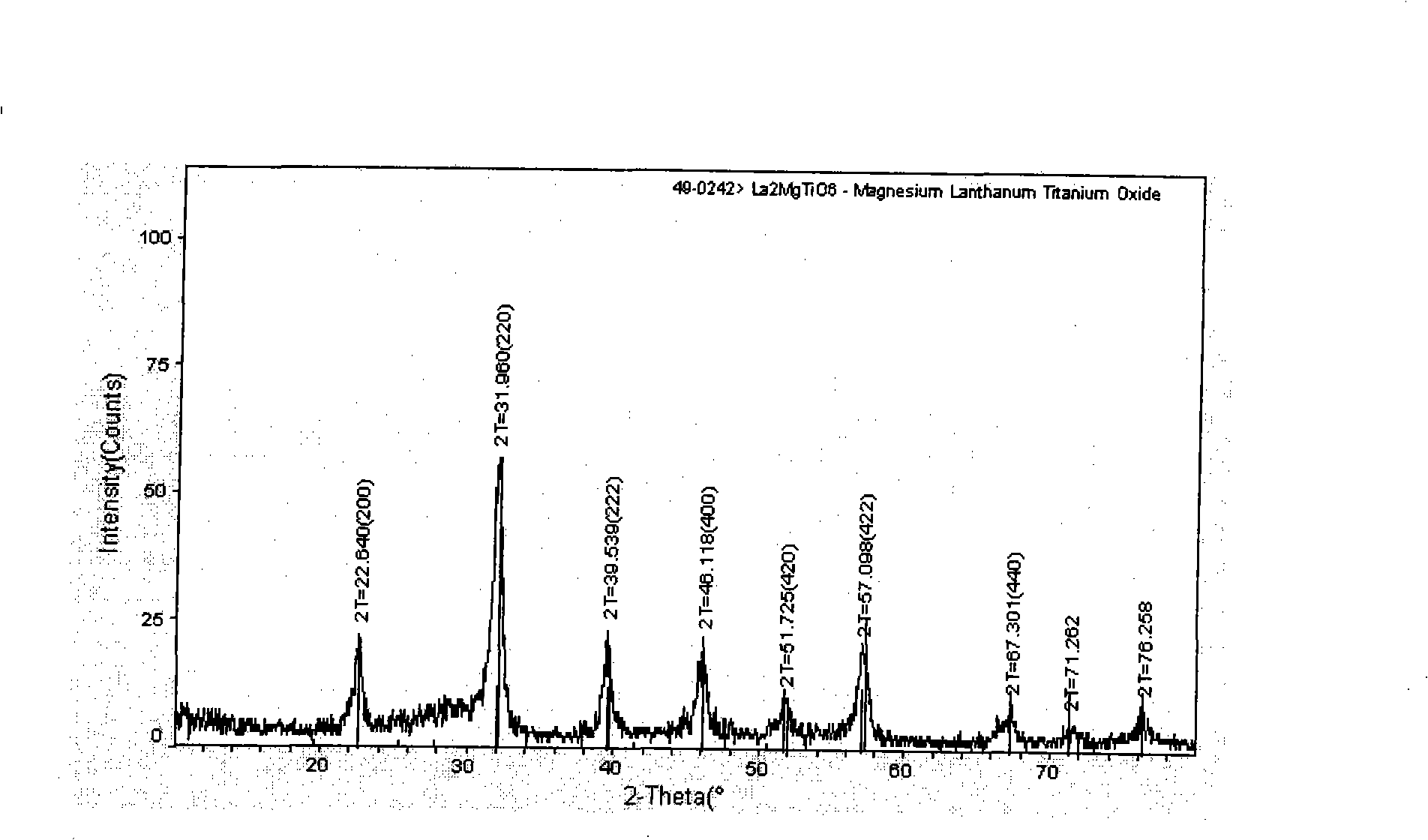

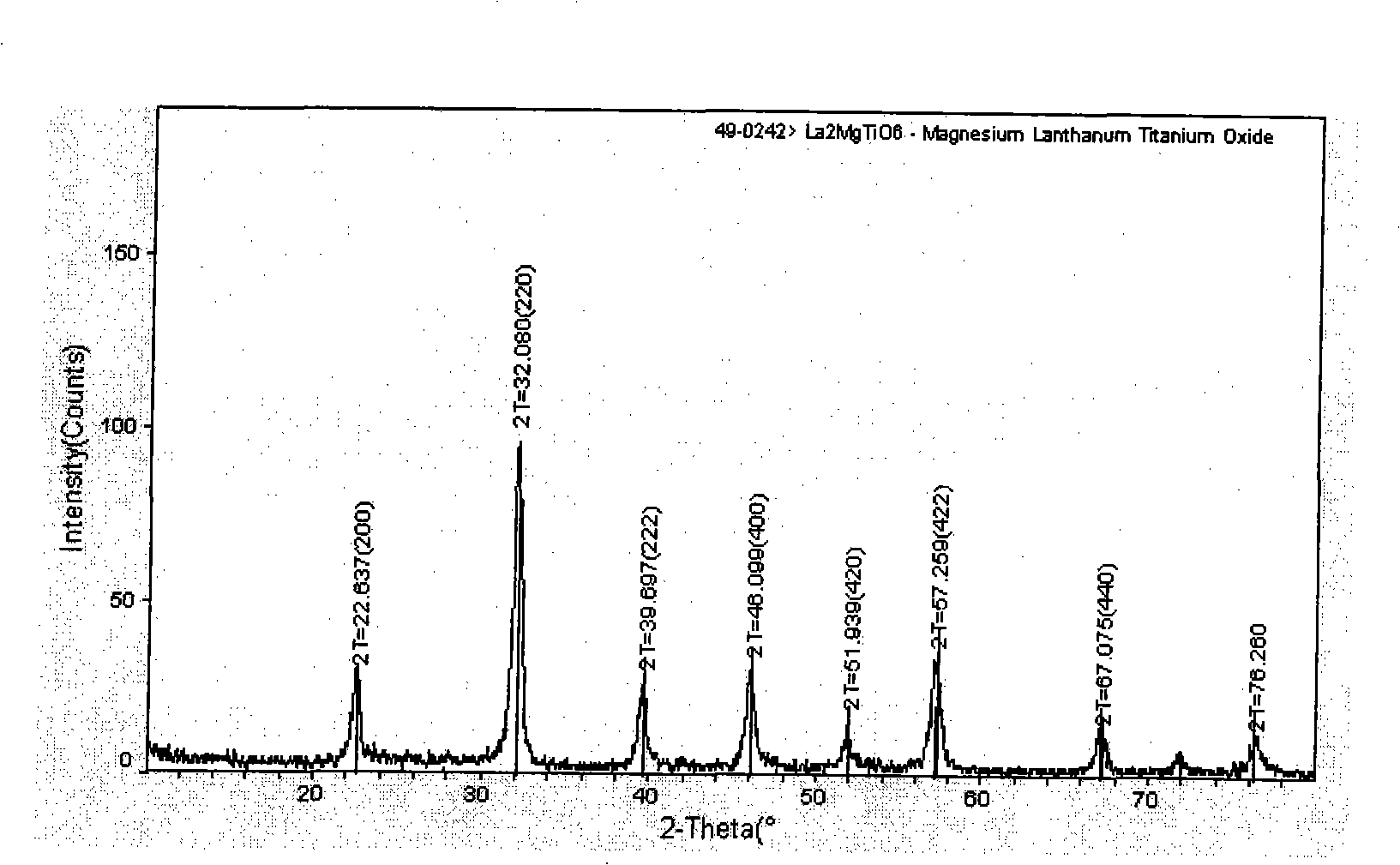

[0016] The present invention will be further described with a specific example below: 10 mL of butyl titanate is added to 10 mL of 95% ethanol that is constantly stirred to produce a white precipitate, to which 0.5 mL of concentrated nitric acid is added dropwise until the precipitate is completely dissolved to obtain Transparent solution; weigh 25.997 grams of lanthanum nitrate and 7.6939 grams of magnesium nitrate, dissolve the above-mentioned lanthanum nitrate and magnesium nitrate in 200 mL of deionized water, then add 25.00 grams of glucose and dissolve in the above-mentioned deionized aqueous solution to make it fully form a complex solution , then stirred at a constant temperature in a water bath at 70°C, evaporated water, and formed a gel within 24 hours, dried the obtained colloid to obtain dry glue, and roasted in air at 500°C, 800°C and 1100°C for 3 hours to obtain La 2 MgTiO 6 catalyst.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com