Method for improving structure and performance of T92 steel welding joint and T92 steel welding joint

A technology of welded joints and properties, applied to improve the microstructure and properties of T92 steel welded joints, in the field of T92 steel welded joints, can solve the problems of lack of theoretical research on welding impact toughness

Inactive Publication Date: 2017-05-10

中国大唐集团科学技术研究总院有限公司

View PDF5 Cites 14 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The research on welding materials and welding processes is mainly aimed at meeting the minimum requirements of the ASME standard for the impact toughness of

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

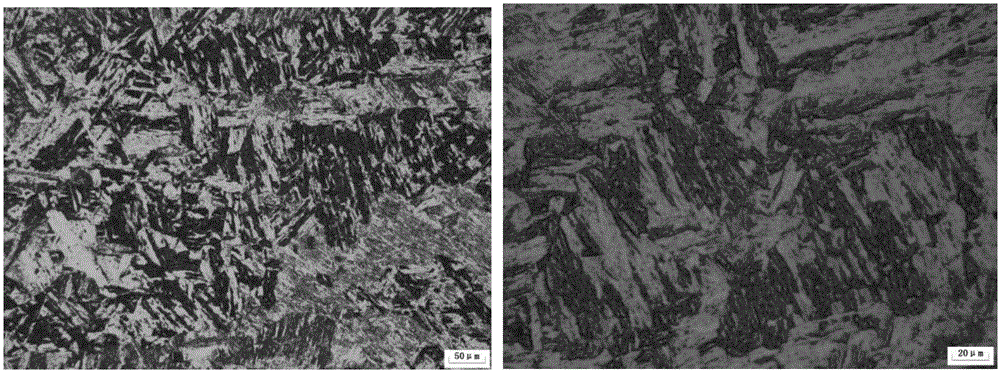

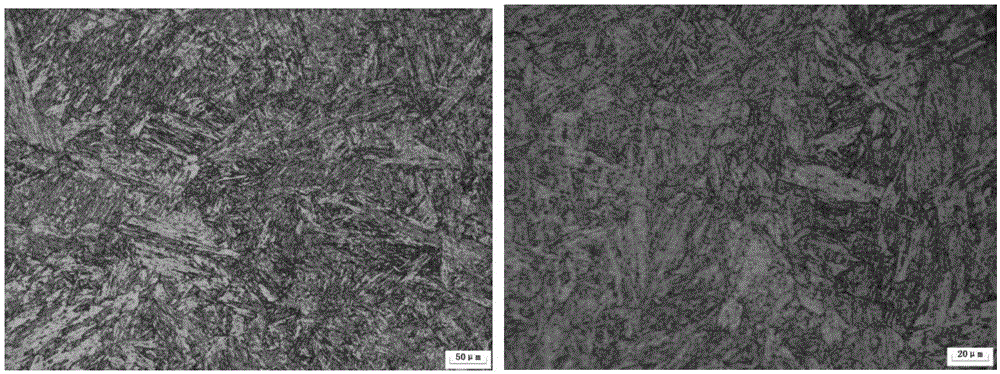

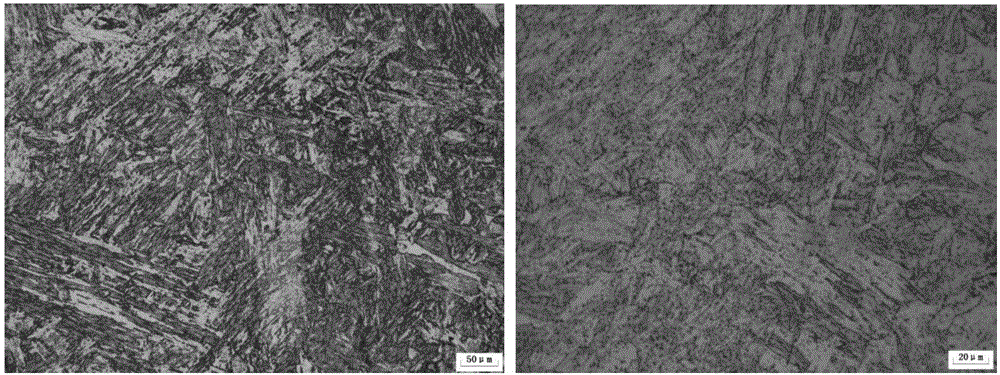

The invention relates to a method for improving the structure and performance of a T92 steel welding joint. By means of a test on deposited metal and the welding joint, the weldability of heat-resistant steel of T/92 steel ferrite is analyzed, the mechanical property of the three kinds of deposited metal different in component and the welding joint is analyzed, comparative study is carried out on the weldability and the weldability of imported welding wires, the influence mechanism of the nickel content and different postweld heat treatment processes and cooling speeds on the structure and the mechanical property of the T/P92 ferrite heat-resistant steel welding joint is analyzed, and control over the preheating temperature, heat input, interlayer temperature and postweld heat treatment process of the T92 steel welding joint and the nickel content are obtained.

Description

technical field [0001] The invention relates to a method for improving the structure and performance of T92 steel welded joints and the T92 steel welded joints. Background technique [0002] In order to improve the power generation efficiency of thermal power plants, reduce CO2 gas emissions and massive fuel consumption, countries all over the world are developing supercritical and supercritical supercritical units. However, the development of materials with long service life under high temperature and high pressure has become the key to the development of supercritical and ultra-supercritical units. [0003] During the T92 welding process, the impact toughness of the welded joint is much lower than that of the base metal, which is a prominent problem encountered in the application process of T92 steel. Since the toughness of T92 steel decreases very quickly after aging, improving the toughness of welded joints before aging to increase the toughness reserve of the joint is...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B23K31/12

CPCB23K31/12

Inventor 张新吴智泉张志刚王泽璞王然陈鑫贾嘉王丽伟

Owner 中国大唐集团科学技术研究总院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com