Sacrificial layer of MEMS (Micro-Electro-Mechanical-System) device, MEMS device and manufacturing method thereof

A manufacturing method and sacrificial layer technology, applied in the field of sacrificial layers, can solve problems such as contamination of the chamber and easy decomposition of the sacrificial layer, and achieve the effects of high viscosity, large material selection range, and easy planarization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

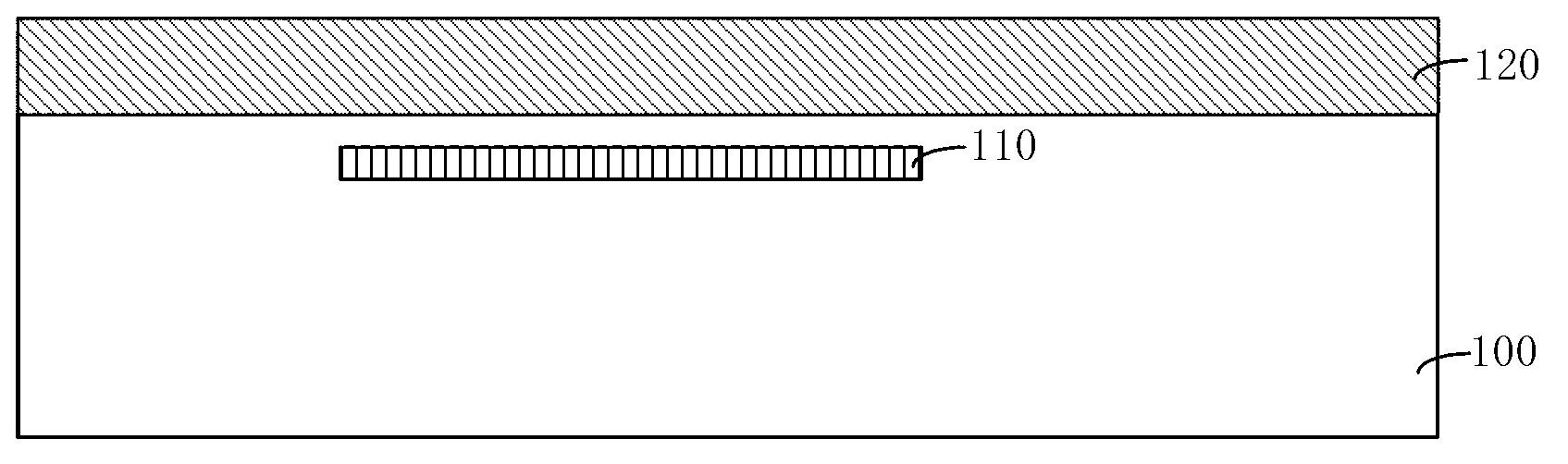

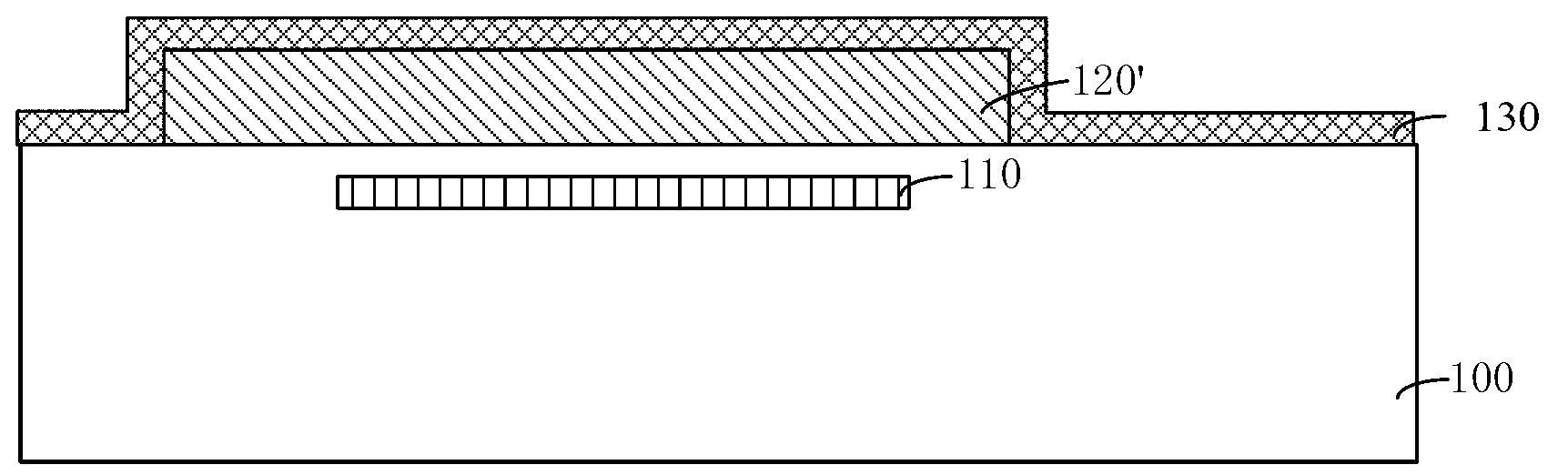

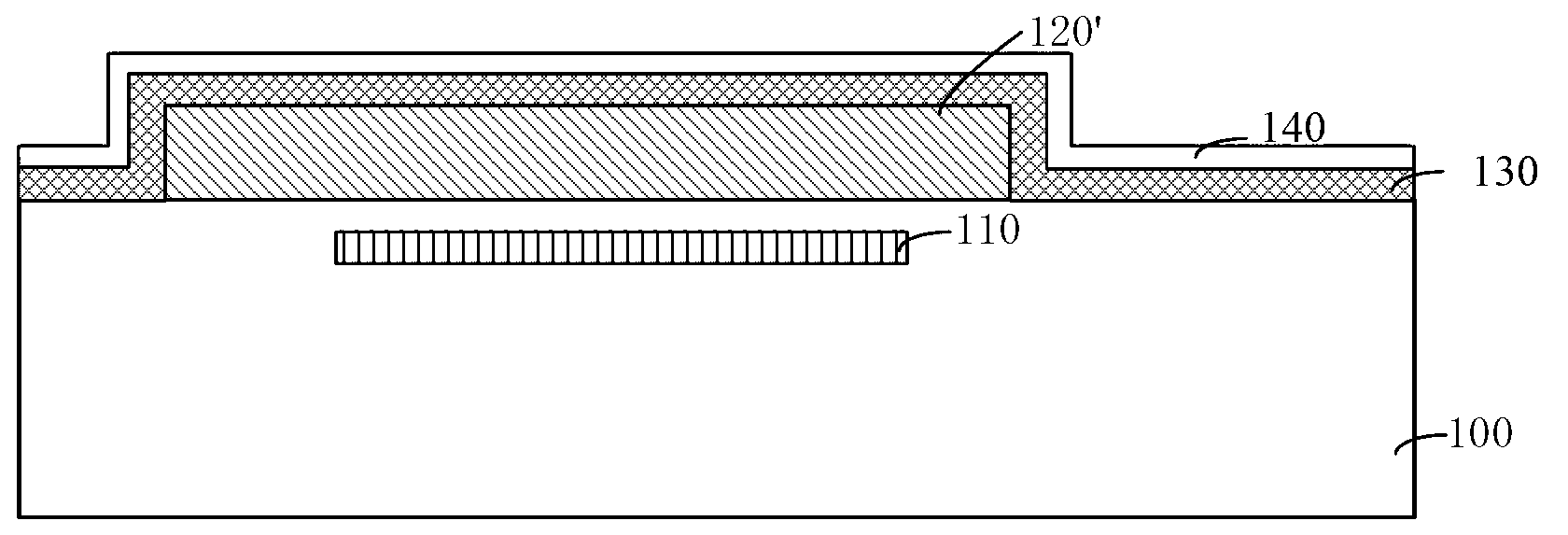

[0036] Figure 1 to Figure 5 Shown is a schematic structural diagram of the manufacturing method of the MEMS pressure sensor provided in this embodiment. The following combination Figure 1 to Figure 5 , through the fabrication method of the MEMS pressure sensor, the technical solution of the sacrificial layer provided by the present invention is introduced in detail.

[0037] Execute step S11: if figure 1 As shown, a semiconductor substrate 100 is provided, and a fixed electrode 110 is formed on the semiconductor substrate 100 . The fixed electrode 110 can be made of metal, or can be made of a semiconductor material containing a dopant (such as silicon material containing germanium). Of course, the fixed electrode 110 can also be made of other conductive materials. In addition, when active components, passive components or metal interconnection layers are formed in the semiconductor substrate 100 , the corresponding conductive components can also be used as the fixed electr...

Embodiment 2

[0053] The sacrificial layer of the MEMS pressure sensor provided in the second embodiment, the MEMS pressure sensor and its manufacturing method are substantially the same as those in the first embodiment. The difference is that the covering layer in the sacrificial layer is made of low temperature oxide (Low Temperature Oxide, LTO) instead of SOG. The low-temperature oxide is a kind of oxide, which can withstand high temperature, and its formation temperature is relatively low, generally not higher than 200°C. The low-temperature oxide can also isolate the organic material layer 120 from the pattern structure material when the pattern structure material is subsequently deposited on it, avoiding the high temperature of the deposition process to cause the organic material to decompose and escape, thereby achieving the goal of avoiding contamination of the deposition. The purpose of accumulating process chambers.

[0054] It can be understood that the MEMS pressure sensor is u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com