Alterant of iron-rich phase in secondary aluminum and alteration method

A technology of recycled aluminum and modificator, which is applied in the field of modified iron-rich phase modifier and metamorphic agent in recycled aluminum. Performance and processability, growth inhibition, effects of reducing growth time and growth space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Heat 70% of the 1# component recycled aluminum to 400°C, keep it warm for 10 minutes, and then raise the temperature to 800°C;

[0030] (2) Add the [Mn] agent with an Mn / Fe atomic ratio of 0.65 at 250°C, and the added [Mn] agent is Al-30%Mn, the amount added is about 2.6% of the total amount of 1# recycled aluminum, and stirred slowly ;

[0031] (3) After the [Mn] agent is melted, add the remaining 1# component recycled aluminum to make the melt temperature drop to 710-720°C;

[0032] (4) Add the [B] agent with a B / Fe atomic ratio of 1 / 120, and the added [B] agent is Al-3%B, the addition amount is about 0.27% of the total amount of 1# secondary aluminum, and stir slowly;

[0033] (5) After the [B] agent is melted, it is refined and cast after standing for 2 hours to obtain a recycled aluminum casting after deterioration treatment.

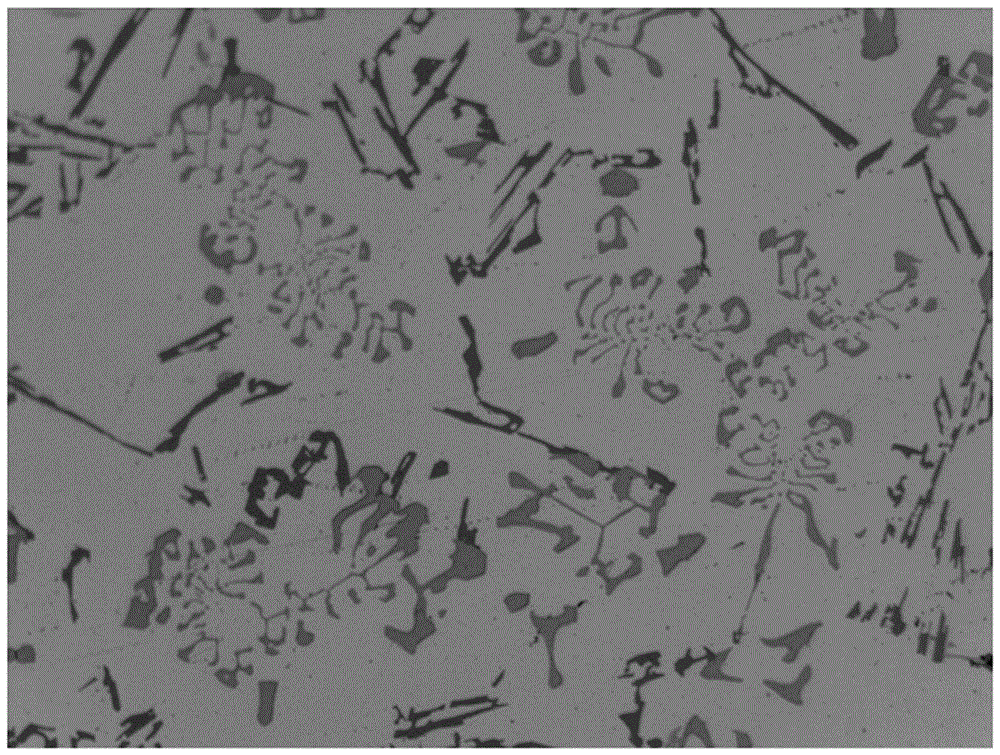

[0034] Such as figure 1As shown, no needle flakes and coarse primary iron-rich phases were found in the metallography of the casting...

Embodiment 2

[0036] (1) Heat 70% of the 2# component recycled aluminum to 400°C, keep it warm for 30 minutes, and then raise the temperature to 780°C;

[0037] (2) Add the [Mn] agent with the Mn / Fe atomic ratio of 0.45 at 250°C, and the added [Mn] agent is Al-40%Mn and Al-10%Cr, and the addition amount is the total amount of 1# recycled aluminum 1.2%, 0.35% of , stirring slowly;

[0038] (3) After the [Mn] agent is melted, add the remaining 3# component recycled aluminum to make the melt temperature drop to 710-720°C;

[0039] (4) Add the [B] agent with a B / Fe atomic ratio of 1 / 60, and the added [B] agent is KBF 4 , the amount of addition is about 0.26% of the total amount of 1# secondary aluminum, stirring slowly;

[0040] (5) After the [B] agent is melted, it is refined and cast after standing for 1 hour to obtain a recycled aluminum casting after deterioration treatment.

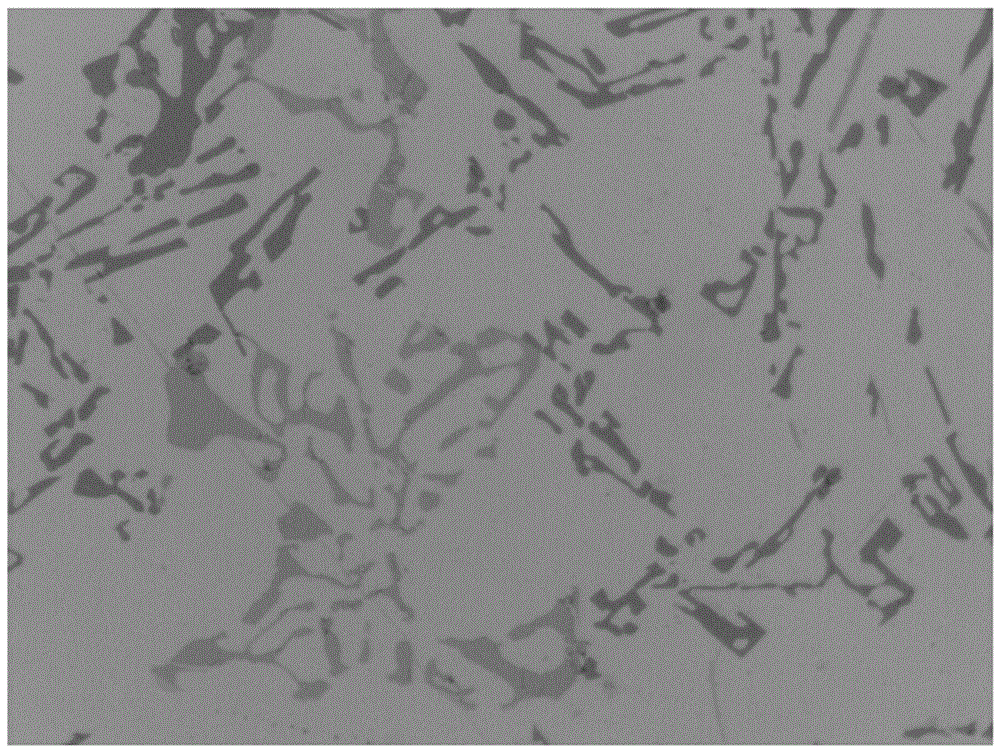

[0041] Such as figure 2 It can be seen that no needle flakes and coarse primary iron-rich phases were found in...

Embodiment 3

[0043] (1) Heat 70% of the 3# component recycled aluminum to 400°C, keep it warm for 25 minutes, and then raise the temperature to 760°C;

[0044] (2) Add the [Mn] agent with a Mn / Fe atomic ratio of 0.30 at 250°C, and the added [Mn] agent is Al-10%Mn, Al-40%Cr and Al-10%Co, and the addition amounts are respectively 2.6%, 0.10%, 0.10% of the total amount of recycled aluminum in 3#, stir slowly;

[0045] (3) After the [Mn] agent is melted, add the remaining 3# component recycled aluminum to make the melt temperature drop to 710-720°C;

[0046] (4) Add the [B] agent with a B / Fe atomic ratio of 1 / 40, and the added [B] agent is Al-5%B and KBF 4 The mixture, the addition amount is about 0.10% and 0.33% of the total amount of 3# recycled aluminum, and stir slowly;

[0047] (5) After the [B] agent is melted, it is refined and cast after standing for 2 hours to obtain a recycled aluminum casting after deterioration treatment.

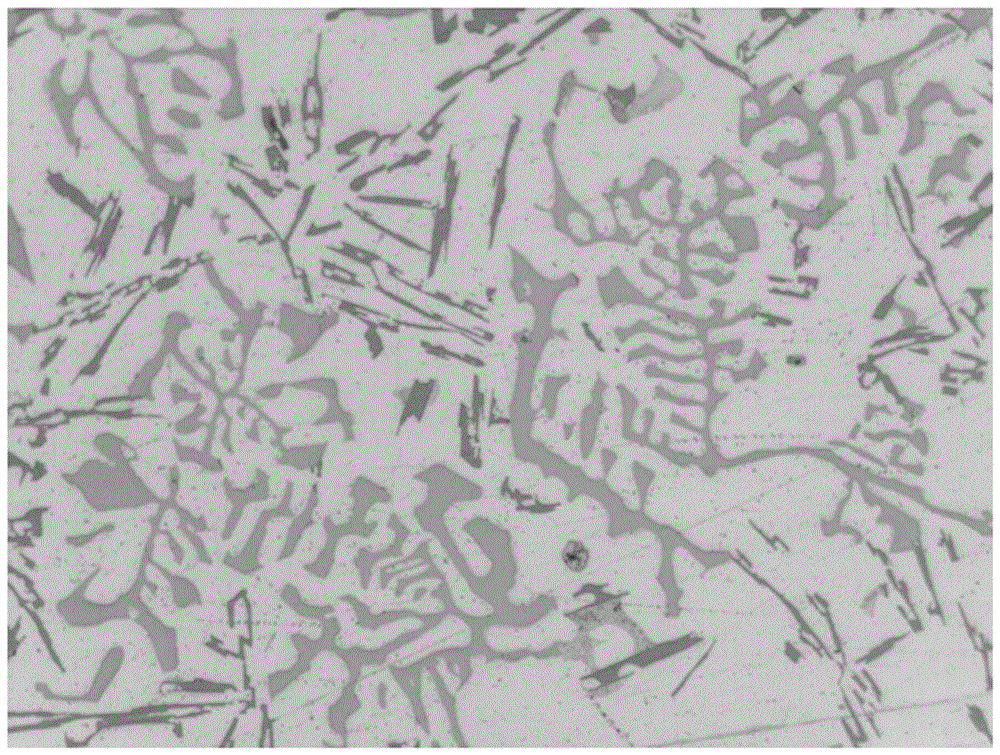

[0048] Such as image 3 As shown, no needle flakes and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com