Raw material composition capable of being used for preparing mesocarbon microbeads (MCMB), preparation method thereof and preparation method of MCMB anode material

A technology of mesophase carbon microspheres and raw material composition, which is applied in the fields of carbon preparation/purification, battery electrodes, electrical components, etc., can solve the problems of complicated and tedious processes, reduce the yield of microspheres, etc., and achieves simple production process steps, Reduced process cost and low reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A raw material composition that can be used for pyrolysis to prepare mesophase carbon microspheres, the raw material composition is a suspension formed after the coal tar pitch extract is dispersed in simethicone oil, and the quality of the simethicone oil is the same as the coal tar pitch extract 3 times the amount of the substance; the coal tar pitch extract is the insoluble matter obtained after the coal tar pitch powder is dissolved in n-hexane to remove impurities.

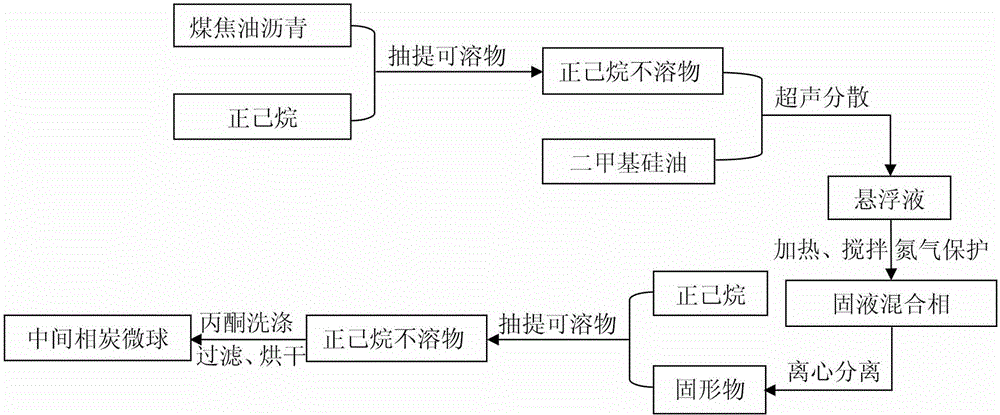

[0028] The above-mentioned raw material composition of the present embodiment is mainly prepared by the following steps (for the process flow chart, see figure 1 ):

[0029] (1) Take high-temperature coal tar pitch and grind it into coal tar pitch powder, and pass through a 250-mesh sieve;

[0030] (2) Put the above-mentioned coal tar pitch powder into a Soxhlet extractor, and then use n-hexane as an organic solvent to extract n-hexane insoluble matter from the high-temperature coal tar pitch powder u...

Embodiment 2

[0038] A raw material composition that can be used for pyrolysis to prepare mesophase carbon microspheres, the raw material composition is a suspension formed after the coal tar pitch extract is dispersed in simethicone oil, and the quality of the simethicone oil is the same as the coal tar pitch extract 3 times the amount of the substance; the coal tar pitch extract is the insoluble matter obtained after the coal tar pitch powder is dissolved in toluene to remove impurities.

[0039] The above-mentioned raw material composition of the present embodiment mainly adopts the following steps to prepare (technical process and figure 1 similar):

[0040] (1) Take medium-temperature coal tar pitch and grind it into coal tar pitch powder, and pass through a 300-mesh sieve;

[0041](2) Put the above-mentioned coal tar pitch powder into a Soxhlet extractor, and then use toluene as an organic solvent to extract toluene-insoluble matter from medium-temperature coal tar pitch powder using...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com