Production process for dexamethasone sodium phosphate bulk medicament

A technology of dexamethasone sodium phosphate and production process, which is applied in directions such as drug delivery, drug combination, and pharmaceutical formulation, can solve problems such as harm and small amount of propylene glycol, and achieves the advantages of simplifying production process steps, reducing propylene glycol and improving stability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

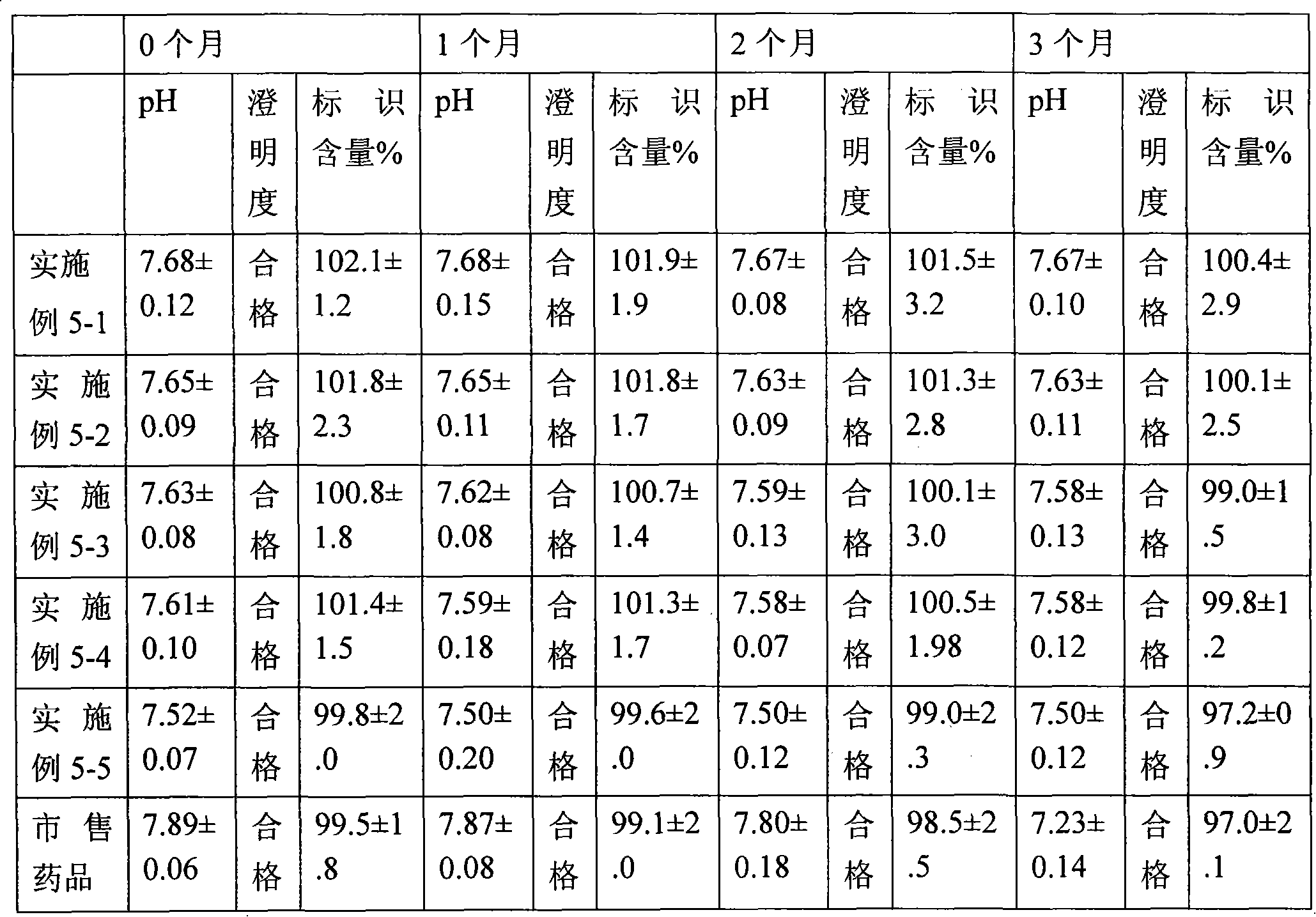

Examples

Embodiment 1

[0035] Dexamethasone Sodium Phosphate 10g

[0036] Water for injection 100g

[0037] (1) Dissolve the prescribed amount of dexamethasone sodium phosphate in the prescribed amount of water for injection, and stir until completely dissolved to obtain the medicinal solution (1).

[0038] (2) Spray-drying the medicinal solution (1) to obtain the bulk drug of dexamethasone sodium phosphate. The spray drying conditions are as follows:

[0039] Hot air flow: 0.55m 3 / min

[0040] Hot air inlet temperature: 110°C

[0041] Outlet temperature: 85°C

[0042] Hot air pressure (gauge pressure): 120kpa

[0043] Liquid flow rate: 5ml / min

[0044] (3) Subpackaging the dexamethasone sodium phosphate bulk drug obtained in step (2) through the inspection of the bulk drug of dexamethasone sodium phosphate.

Embodiment 2

[0046] Dexamethasone Sodium Phosphate 10g

[0047] Water for injection 150g

[0048] (1) Dissolve the prescribed amount of dexamethasone sodium phosphate in the prescribed amount of water for injection, and stir until completely dissolved to obtain the medicinal solution (1).

[0049] (2) Spray-drying the medicinal solution (1) to obtain the bulk drug of dexamethasone sodium phosphate. The spray drying conditions are as follows:

[0050] Hot air flow: 0.65m 3 / min

[0051] Hot air inlet temperature: 115°C

[0052] Outlet temperature: 90°C

[0053] Liquid flow rate: 5ml / min

[0054] Hot air pressure (gauge pressure): 130kpa

[0055] (3) Subpackaging the dexamethasone sodium phosphate bulk drug obtained in step (2).

Embodiment 3

[0057] Dexamethasone Sodium Phosphate 10g

[0058] Water for injection 150g

[0059] (1) Dissolve the prescribed amount of dexamethasone sodium phosphate in the prescribed amount of water for injection, and stir until completely dissolved to obtain the medicinal solution (1).

[0060] (2) The liquid medicine (1) is filtered and sterilized with a G6 glass vertical melting funnel, and treated for depyrogenation.

[0061] (3) Spray-dry the medicinal solution (1) to obtain dexamethasone sodium phosphate bulk drug powder. The spray drying conditions are as follows:

[0062] Hot air flow: 0.75m 3 / min

[0063] Hot air inlet temperature: 120°C

[0064] Outlet temperature: 90°C

[0065] Liquid flow rate: 10min / L

[0066] Hot air pressure (gauge pressure): 140kpa

[0067] (4) The dexamethasone bulk drug powder obtained in step (3) is aseptically subpackaged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com