Alite-barium calcium sulfur aluminate cement

The technology of barium calcium sulfoaluminate and calcium ferric aluminate is applied in the field of cement materials, which can solve the problems of high cost and unsuitability for mass production, and achieve the effects of accelerating hardening speed, saving limestone resources and reducing shrinkage rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0035] The specific examples of Alite-barium calcium sulfoaluminate cement of the present invention are shown in Table 1, Table 2 and Table 3.

[0036] Numbering

[0037] Prepare the raw meal according to the above six ingredients, and add a small amount of fluorite at the same time, according to CaF 2 Calculated as 0.6 to 1.2%. The chemical composition of the raw meal is shown in Table 2

[0038] Numbering

[0039] In the laboratory, the above clinker is fired in a silicon-molybdenum rod electric furnace, and the firing temperature is 1360°C-1380°C. The physical properties of cement are listed in Table 3.

[0040]

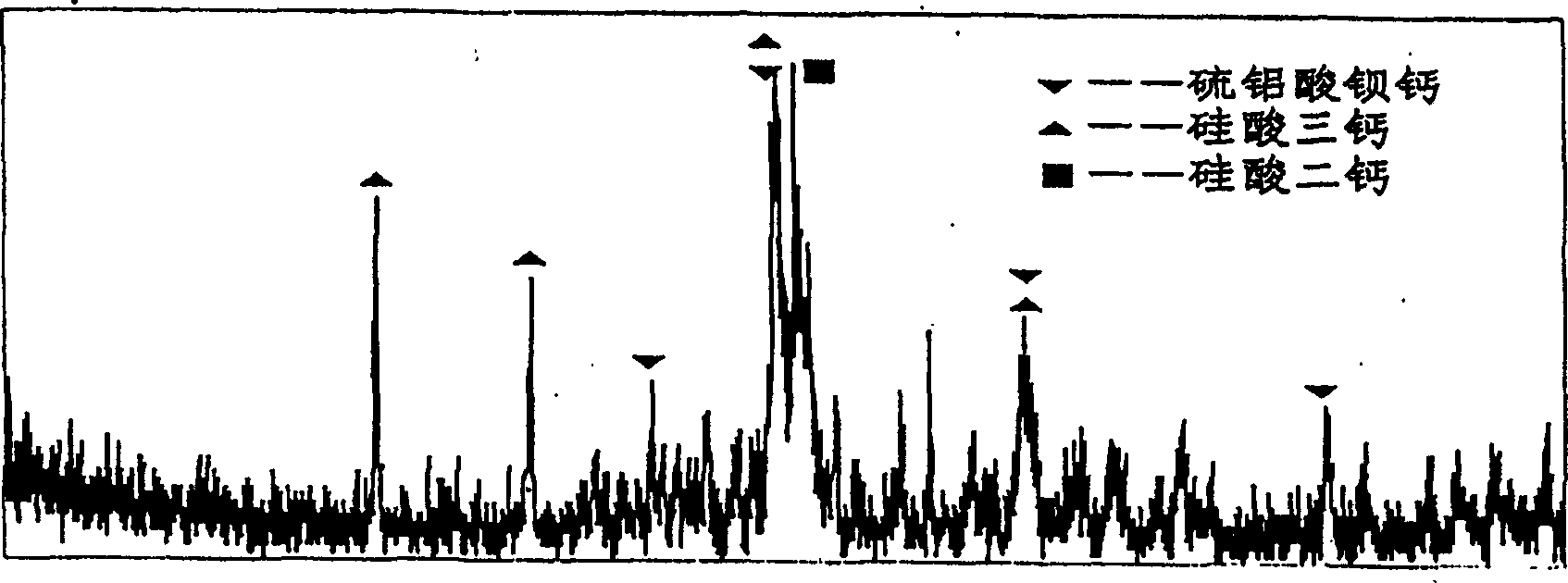

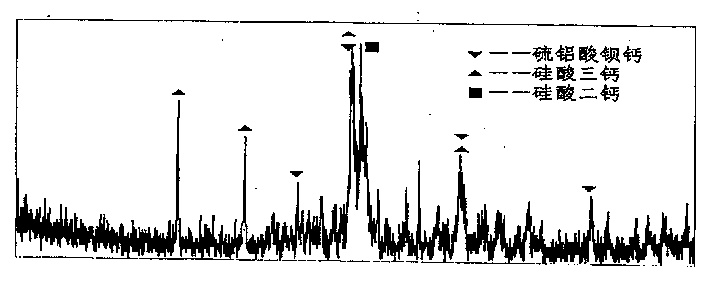

[0041] The 3# clinker was analyzed by XRD, as shown in Figure 1. It can be seen that in the alite-barium calcium sulfoaluminate cement clinker mineral system, a certain amount of alite and barium calcium sulfoaluminate minerals are formed, which further shows that the compounding and coexistence of these two minerals can achieve ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com