A kind of high-strength Portland cement clinker and its preparation method

A Portland cement, high-strength technology, applied in clinker production, cement production, etc., can solve the problems of low S content and unoptimized cement clinker mineral content, and achieve the effect of reducing carbon emissions and strengthening early strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

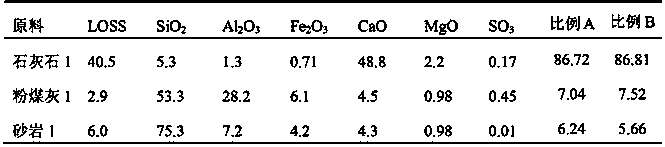

[0036] Use industrial raw materials (see Table 1) for batching.

[0037] Composition analysis of table 1 raw material, XRF analysis result (%)

[0038]

[0039] Add gypsum (CaSO 4 2H 2 O), prepared raw meal. The prepared raw material is pressed and calcined, and the temperature is raised to 900°C at a rate of 10°C / min, kept at a temperature of 40 minutes, and then heated at a rate of 5°C / min to a firing temperature of 1500°C, kept at a temperature of 60 minutes, and fired The clinker was cooled to room temperature in the air at a speed of 70°C / min, and blank samples of A and B were obtained. The cooled clinker was heated at 10°C / min to 1230°C for 60 minutes, and then cooled to room temperature at 80°C / min to obtain samples after treatment of A and B.

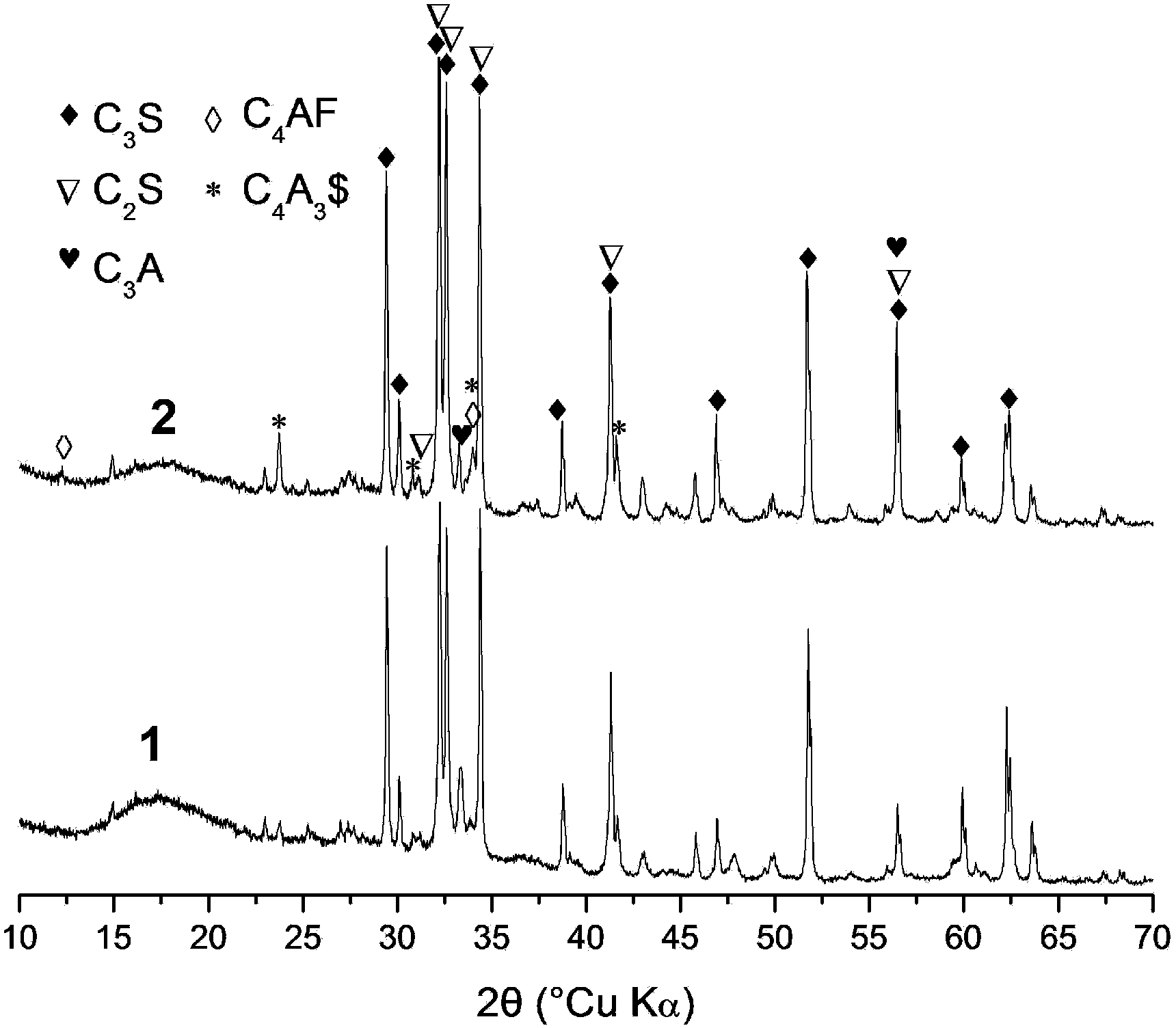

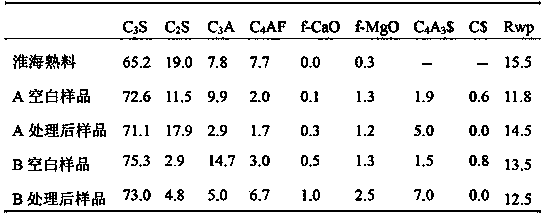

[0040] The XRD spectrum of the clinker is attached figure 1 Shown: where C 4 A 3 $ is calcium sulfoaluminate, qualitative analysis shows that calcium sulfoaluminate minerals exist in the sample, other cement clinker mi...

Embodiment 2

[0047] Use industrial raw materials (see Table 4) for batching.

[0048] Table 4. Composition analysis of raw materials, XRF analysis results (%)

[0049]

[0050] Table 5. Ratio of ingredients (%)

[0051]

[0052] Add gypsum (CaSO 4 2H 2 O), the raw meal is prepared, and the proportion of ingredients is shown in Table 5. The prepared raw material is pressed and calcined, and the temperature is raised to 1000°C at a rate of 30°C / min, kept at a temperature of 30 minutes, and then heated at a rate of 10°C / min to a firing temperature of 1400°C, kept at a temperature of 30 minutes, and fired The clinker is cooled to room temperature (15-40°C) in the air at a speed of 90°C / min. Heat the cooled clinker at 30°C / min to 1290°C for 5 minutes, then cool to room temperature at 50°C / min. The mineral content of the fired clinker was calculated by Rietveld full-spectrum fitting, and the results are shown in Table 6. In the test, a silicate clinker sample normally produced by a c...

Embodiment 3

[0061] Use industrial limestone, fly ash and sandstone for experiments. Its components are shown in Table 9:

[0062] Table 9 Analysis of each component of raw materials (%)

[0063]

[0064] The dry basis ratio of each raw material is limestone: 82.92%, fly ash: 12.38%, sandstone: 5.51%. Add CaSO with a mass fraction of 8.3% 4 2H 2 O. The prepared raw material is pressed and calcined, and the temperature is raised to 950°C at a rate of 25°C / min, kept for 30 minutes, and then heated to the firing temperature Ts at a rate of 10°C / min, the calcining time is ts, and then moved quickly The sample arrives at the T1 section of constant temperature, and after heat preservation treatment (holding time t1), it is moved to the T2 section for heat preservation (holding time t2). After the processed sample is taken out, it is cooled at 80°C / min. The temperature of the tube furnace was calibrated with a Ferro temperature measuring ring (±5°C). Mineral quantification was performed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com