A kind of green mortar made from construction waste and its preparation method

A kind of construction waste and green technology, applied in the field of building materials, can solve the problems of ordinary mortar reaching the predetermined strength for a long time, not meeting the performance requirements of light weight and environmental protection, and environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

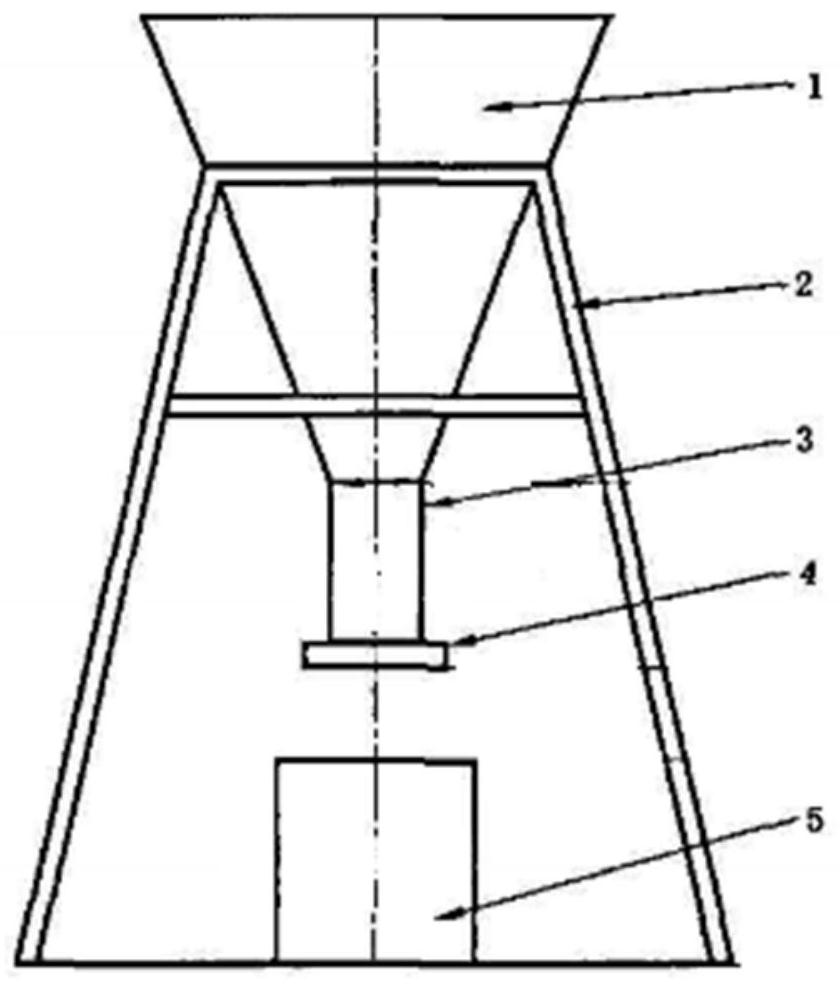

Image

Examples

Embodiment 1~6

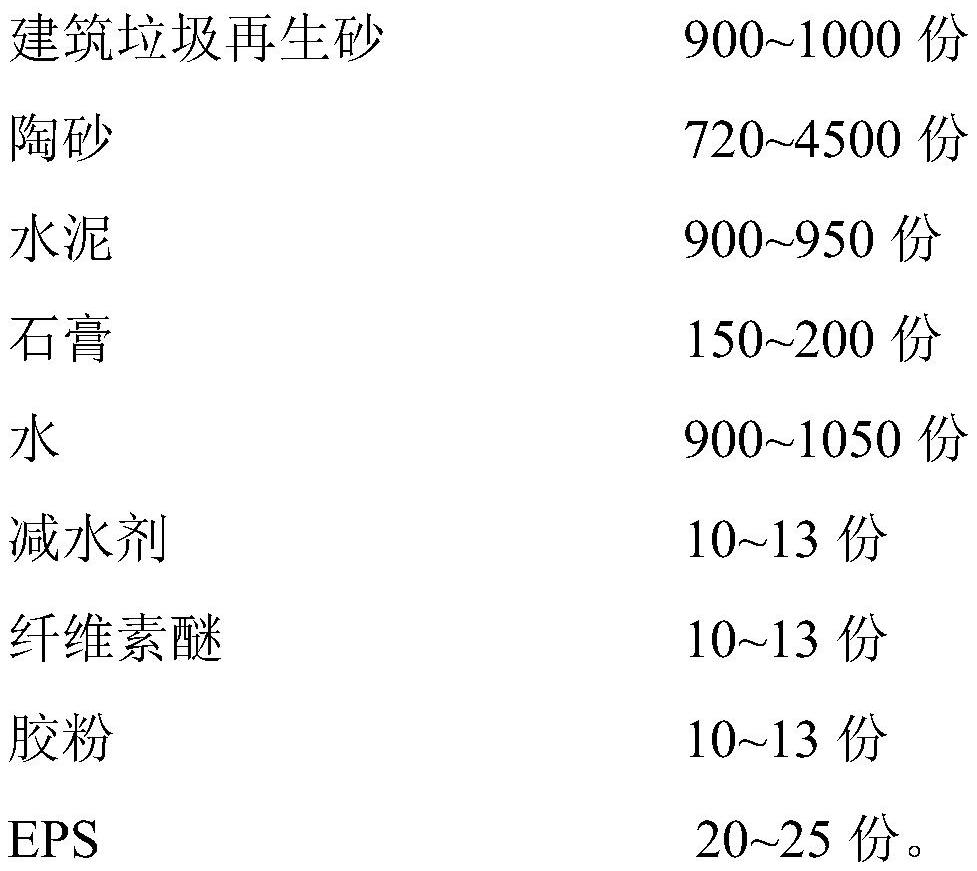

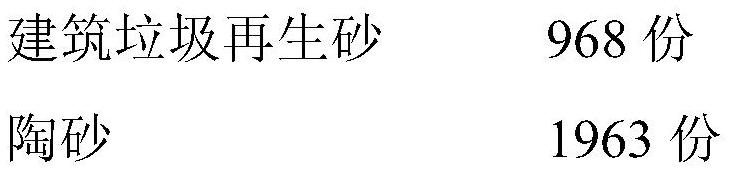

[0037] A kind of green mortar made from construction waste, the raw materials for preparation include the following components in parts by weight: regenerated sand from construction waste, cement, gypsum, pottery sand, water, water reducing agent, cellulose ether, rubber powder, EPS, specifically The component content is shown in Table 1; the raw material for the preparation of reclaimed sand from construction waste is selected from industrial waste fly ash; the fineness modulus of reclaimed sand from construction waste is 3.77, and the apparent density is 1613kg / m 3 ; The fineness modulus of pottery sand is 3.29, and the apparent density is 818kg / m 3 ; The water reducing agent is an amino high-efficiency water reducing agent; the rubber powder is a ternary copolymerization rubber powder of ethylene, polyethylene and vinyl laurate.

[0038] The preparation method of the green mortar made from construction waste in the present embodiment is:

[0039] (1) Take construction wast...

Embodiment 7~12

[0089] A kind of green mortar made from construction waste, the raw materials for preparation include the following components in parts by weight: regenerated sand from construction waste, cement, gypsum, pottery sand, perlite, water, water reducing agent, cellulose ether, rubber powder, EPS, see Table 4 for specific component contents.

[0090] In the composition of raw materials, the raw materials for the preparation of construction waste recycled sand are selected from construction waste; the fineness modulus of construction waste recycled sand is 3.77, and the apparent density is 1613kg / m 3 ; The fineness modulus of pottery sand is 3.29, and the apparent density is 818kg / m 3 ; The water reducer is an amino high-efficiency water reducer; the rubber powder is a ternary copolymer rubber powder of vinyl acetate, ethylene and higher fatty acid vinyl ester.

[0091] The preparation method of the green mortar made from construction waste in the present embodiment is:

[0092] (...

Embodiment 13~14

[0113] A kind of green mortar made from construction waste, the raw materials for preparation include the following components in parts by weight: regenerated sand from construction waste, cement, gypsum, pottery sand, water, water reducing agent, cellulose ether, rubber powder, EPS, specifically The component content is shown in Table 8; the raw material for the preparation of reclaimed sand from construction waste is selected from industrial waste fly ash; the fineness modulus of reclaimed sand from construction waste is 3.84, and the apparent density is 1538kg / m 3 ;The fineness modulus of pottery sand is 3.19, and the apparent density is 847kg / m 3 ; The water reducing agent is an amino high-efficiency water reducing agent; the rubber powder is a ternary copolymerization rubber powder of ethylene, polyethylene and vinyl laurate. The preparation method in this example is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com