Ocean engineering repair mortar and preparation method thereof

A technology for repairing mortar and marine engineering, used in the field of marine engineering building materials, can solve the problems of low compressive strength, long setting time, easy to crack and collapse, and achieve high early strength, short setting time, and seawater erosion resistance. strong effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

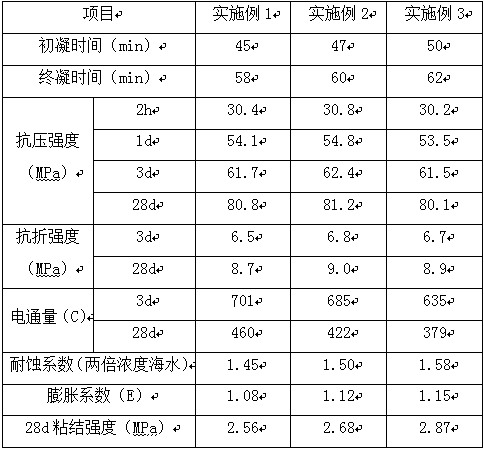

Examples

Embodiment 1

[0028] A marine engineering repair mortar is made of the following raw materials in parts by weight: 20 parts of alite-sulphoaluminate cement, 15 parts of marine portland cement, 1.5 parts of ultra-dispersed shrinkage reducing water reducer, and 5 parts of coagulation regulator , 1 part of reinforcing powder, 1 part of anti-corrosion compacting agent, 6 parts of anti-cracking and waterproof expansion agent, 5 parts of ultrafine mineral powder, 0.1 part of defoamer, 0.5 part of redispersible latex powder, and 50 parts of quartz sand.

[0029] The content of tricalcium silicate in the Alite-sulfoaluminate cement is not more than 5%.

[0030] The ultra-dispersed shrinkage-reducing water reducer is a shrinkage-reducing and toughening-type water reducer prepared by introducing diethylene glycol monobutyl ether groups with shrinkage-reducing effects into polycarboxylate water reducers through modern molecular tailoring technology. , purchased from Hainan Ruize New Building Materials...

Embodiment 2

[0044] A marine engineering repair mortar is made of the following raw materials in parts by weight: 25 parts of Alite-sulfoaluminate cement, 20 parts of marine portland cement, 2.2 parts of ultra-dispersed shrinkage reducing water reducer, and 2.5 parts of coagulation regulator , 3 parts of reinforcing powder, 2.5 parts of anti-corrosion compacting agent, 7 parts of anti-cracking and waterproof expansion agent, 18 parts of ultrafine mineral powder, 0.4 part of defoamer, 1.2 parts of redispersible latex powder, 65 parts of quartz sand.

[0045] The content of tricalcium silicate in the Alite-sulfoaluminate cement is not more than 5%.

[0046] The ultra-dispersed shrinkage-reducing water reducer is a shrinkage-reducing and toughening-type water reducer prepared by introducing diethylene glycol monobutyl ether groups with shrinkage-reducing effects into polycarboxylate water reducers through modern molecular tailoring technology. , purchased from Hainan Ruize New Building Materi...

Embodiment 3

[0060] A marine engineering repair mortar is made of the following raw materials in parts by weight: 30 parts of Alite-sulfoaluminate cement, 25 parts of marine Portland cement, 3 parts of super-dispersed shrinkage-reducing water reducer, 5 parts of reinforcing powder, 4 parts of anti-corrosion compacting agent, 8 parts of anti-cracking and waterproof expansion agent, 30 parts of ultrafine mineral powder, 0.6 part of defoamer, 2 parts of redispersible latex powder, and 80 parts of quartz sand.

[0061] The content of tricalcium silicate in the Alite-sulfoaluminate cement is not more than 5%.

[0062] The ultra-dispersed shrinkage-reducing water reducer is a shrinkage-reducing and toughening-type water reducer prepared by introducing diethylene glycol monobutyl ether groups with shrinkage-reducing effects into polycarboxylate water reducers through modern molecular tailoring technology. , purchased from Hainan Ruize New Building Materials Co., Ltd.

[0063] The reinforcing pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com