A kind of foam concrete containing composite admixture and its preparation method and application

A composite admixture and foam concrete technology, which is applied in the field of thermal insulation materials, can solve the problems of weak hydration reaction, less hydration products, and poor corrosion resistance, and achieve the effects of increasing self-shrinkage, improving mechanical properties, and good durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

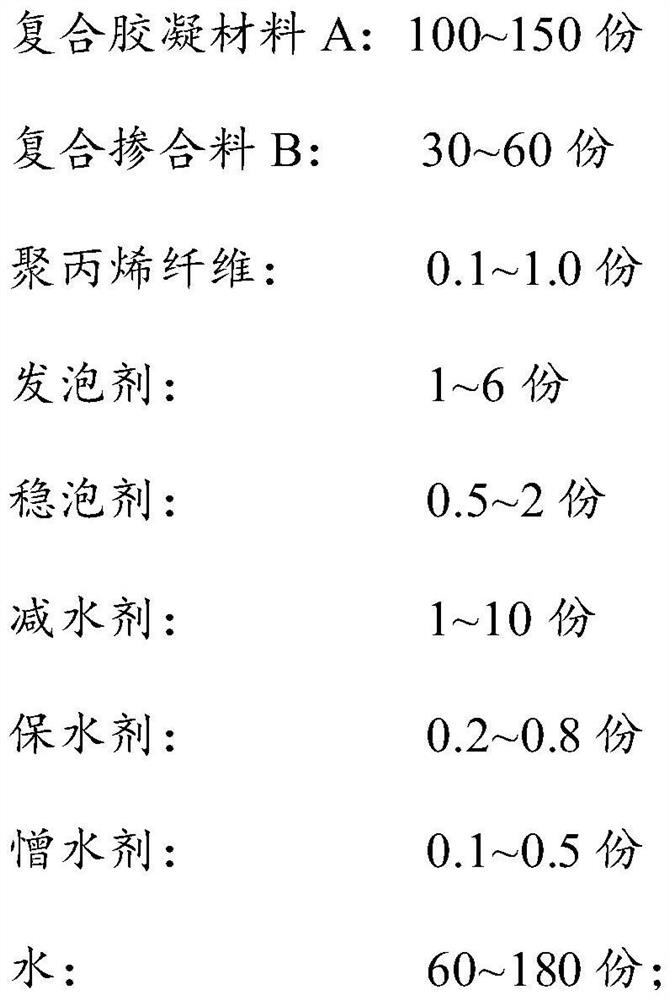

Method used

Image

Examples

Embodiment 1

[0033] Prepare foam concrete (FC) finished product by the following method 1

[0034] 1) Weigh 1 part by weight of foaming agent and 2 parts by weight of foam stabilizer, add 60 parts by weight of water to dilute, add to the foaming machine to prepare foam in advance, and set aside;

[0035] 2) Add 100 parts by weight of composite gelling material A, 50 parts by weight of composite admixture B, 1.0 part by weight of polypropylene fiber, and 1 part by weight of water reducing agent into a mixer, stir and premix to obtain a dry powder, Then add water according to the water-cement ratio of 0.2 to 0.5, and stir well to obtain a slurry;

[0036] 3) Add the prefabricated foam to the above slurry for foaming, then add 0.2 parts by weight of water-retaining agent and 0.5 parts by weight of water-repellent agent, and fully mix and stir;

[0037] 4) Pour into a 100×100×100 mold, shape, demould, and cure, and finally obtain the finished foam concrete 1 .

Embodiment 2

[0039] Preparation of foamed concrete (FC) finished product by the following method 2

[0040]1) Weigh 6 parts by weight of foaming agent and 0.5 parts by weight of foam stabilizer, add 130 parts by weight of water to dilute, add to the foaming machine to prepare foam in advance, and set aside;

[0041] 2) Add 100 parts by weight of composite gelling material A, 30 parts by weight of composite admixture B, 0.1 parts by weight of polypropylene fiber, and 10 parts by weight of water reducing agent into a mixer and stir and premix to obtain a dry powder. Then add water according to the water-cement ratio of 0.2 to 0.5, and stir well to obtain a slurry;

[0042] 3) Add the prefabricated foam to the above slurry for foaming, then add 0.8 parts by weight of water-retaining agent and 0.1 part by weight of water-repellent agent, and fully mix and stir;

[0043] 4) Inject into a 100×100×100 mold, shape, demould, and cure, and finally obtain the finished foam concrete 2.

Embodiment 3

[0045] Preparation of foamed concrete (FC) finished product by the following method 3

[0046] 1) Weigh 3 parts by weight of foaming agent and 1 part by weight of foam stabilizer, add 80 parts by weight of water to dilute, add to the foaming machine to prepare foam in advance, and set aside;

[0047] 2) Add 150 parts by weight of composite gelling material A, 60 parts by weight of composite admixture B, 0.8 parts by weight of polypropylene fiber, and 5 parts by weight of water reducing agent into a mixer and stir and premix to obtain a dry powder. Then add water according to the water-cement ratio of 0.2 to 0.5, and stir well to obtain a slurry;

[0048] 3) Add the prefabricated foam to the above slurry for foaming, then add 0.6 parts by weight of water-retaining agent and 0.1 part by weight of water-repellent agent, and fully mix and stir;

[0049] 4) Pour into a 100×100×100 mold, shape, demould, and cure, and finally obtain the finished foam concrete product 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com