High-performance polycarboxylate superplasticizer and preparation method thereof

A polycarboxylic acid and water reducing agent technology, applied in the field of concrete admixtures, can solve the problems of cement-based materials such as retardation, difficulty in diffusion, and decline in mechanical properties, so as to increase the adsorption thickness, increase the contact area, and enhance the steric hindrance effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

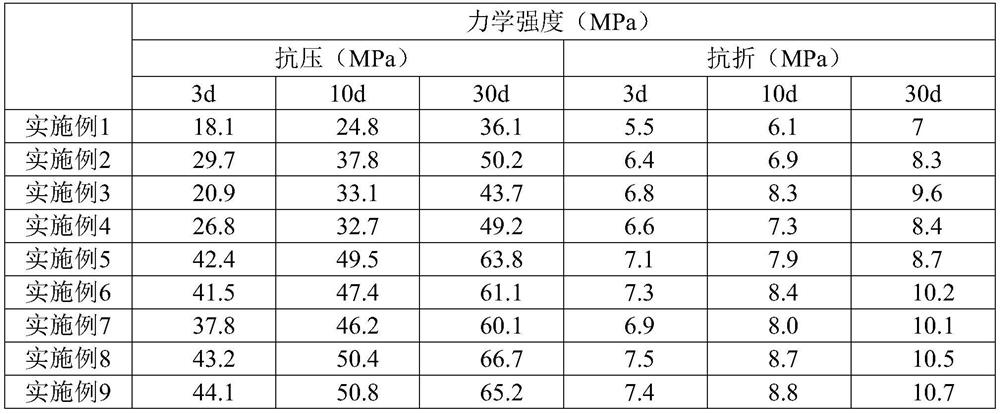

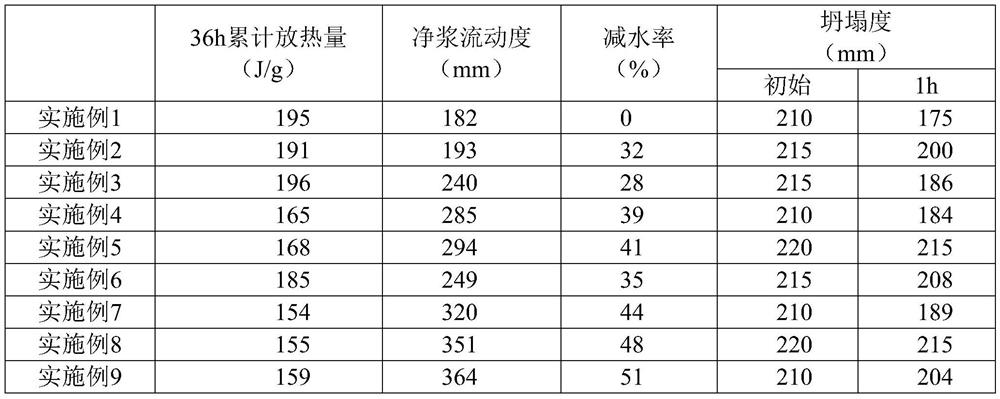

Examples

Embodiment 1

[0033] S1: Activation of the macromolecular monomer: add a small amount of hydrogen peroxide solution dropwise to the terminal alkenyl alkylene polyoxyethylene ether for activation treatment.

[0034] S2: Add the aqueous solution of terminal alkenyl alkylene polyoxyethylene ether and the aqueous solution of maleic anhydride activated in step S1 into the reactor, the maleic anhydride, terminal alkenyl alkylene polyoxyethylene ether, The feed weight ratio of water is 2:10:50;

[0035] S3: slowly drop an aqueous solution of ascorbic acid, hydrogen peroxide, and sodium bisulfite into the reactor, and the weight ratio of the hydrogen peroxide, ammonium persulfate, and sodium bisulfite is 1:0.6;

[0036] S4: Slowly add the aqueous solution of methacrylic acid, mercaptopropionic acid and 2-acrylamido-2-methylpropylsulfonic acid into the reactor dropwise, and the dropwise addition is completed in 3 hours; use sodium hydroxide for 2 hours at room temperature Adjust the pH value of the...

Embodiment 2

[0038] S1: Activation of the macromolecular monomer: add a small amount of hydrogen peroxide solution dropwise to the terminal alkenyl alkylene polyoxyethylene ether for activation treatment.

[0039] S2: Add the aqueous solution of terminal alkenyl alkylene polyoxyethylene ether and the aqueous solution of maleic anhydride activated in step S1 into the reactor, the maleic anhydride, terminal alkenyl alkylene polyoxyethylene ether, The feed weight ratio of water is 2:10:50;

[0040] S3: slowly drop an aqueous solution of ascorbic acid, hydrogen peroxide, and sodium bisulfite into the reactor, and the weight ratio of the hydrogen peroxide, ammonium persulfate, and sodium bisulfite is 1:0.6;

[0041] S4: Slowly add the aqueous solution of methacrylic acid, maleic acid-triethanolamine monoester, mercaptopropionic acid and 2-acrylamido-2-methylpropylsulfonic acid into the reactor dropwise, and the dropwise addition is completed in 3 hours Reaction at normal temperature for 2 hour...

Embodiment 3

[0043] S1: Activation of the macromolecular monomer: add a small amount of hydrogen peroxide solution dropwise to the terminal alkenyl alkylene polyoxyethylene ether for activation treatment.

[0044] S2: Add the aqueous solution of terminal alkenyl alkylene polyoxyethylene ether and the aqueous solution of maleic anhydride activated in step S1 into the reactor, the maleic anhydride, terminal alkenyl alkylene polyoxyethylene ether, The feed weight ratio of water is 2:10:50;

[0045] S3: slowly drop an aqueous solution of ascorbic acid, hydrogen peroxide, and sodium bisulfite into the reactor, and the weight ratio of the hydrogen peroxide, ammonium persulfate, and sodium bisulfite is 1:0.6;

[0046] S4: methacrylic acid, nano-SiO 2 The aqueous solution of mercaptopropionic acid and 2-acrylamido-2-methylpropylsulfonic acid is slowly added dropwise to the reactor, and the dropwise addition is completed in 3 hours; the pH value of the reaction solution is adjusted by using sodium...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com