Epoxy acrylate for UV (ultraviolet) curable coating and preparation method of epoxy acrylate

A technology for epoxy acrylate and curing coatings, applied in the field of coatings, can solve the problems of reduced polymerization shrinkage, lower viscosity of epoxy acrylate resin, flammability, etc., to achieve outstanding heat resistance and water resistance, and increase space volume , The effect of eliminating the problem of phase separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 1) Preparation of hyperbranched polysiloxane

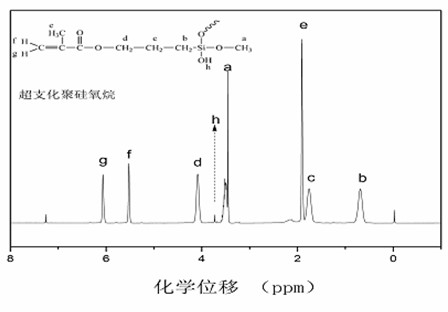

[0031] Refer to the technical scheme disclosed in the Chinese invention patent (publication number CN101570600) to prepare hyperbranched polysiloxane. The specific method is: mix γ-methacryloxypropyltrimethoxysilane with deionized water in a molar ratio of 1: 1.2 Pour into the reaction bottle, adjust pH=2, N 2 protection, heated to 50°C for 5 hours, and dried in a vacuum oven for 3 hours to obtain hyperbranched polysiloxane, whose structural formula is:

[0032]

[0033] In the formula, R is .

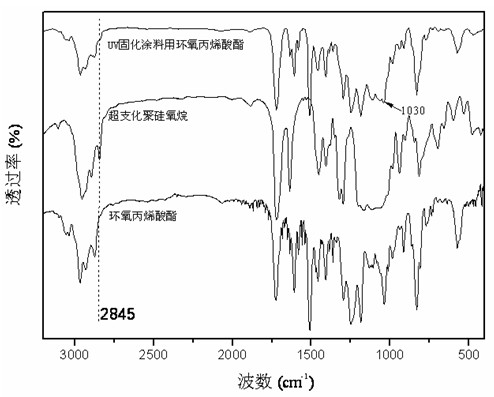

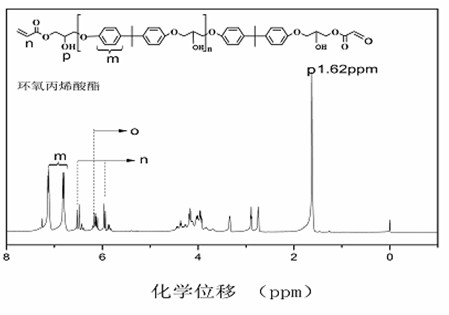

[0034] The hyperbranched polysiloxane that present embodiment provides, its IR, 1 H NMR and 29 Si NMR spectra are shown in the attached figure 1 , 2 and 5. The molecular weight is 2800 g / mol as determined by the multi-angle dynamic laser scattering method.

[0035] 2) Preparation of bisphenol A epoxy acrylate resin

[0036]Add 100g of bisphenol A epoxy resin (grade E51, epoxy value 0.48-0.54) into a 250mL three-necked f...

Embodiment 2

[0046] 1) Preparation of hyperbranched polysiloxane

[0047] Pour vinyltrimethoxysilane and deionized water into the reaction bottle at a molar ratio of 1:1.1, adjust pH=3, N 2 protection, heated to 60°C for 4 hours, and dried in a vacuum oven for 3 hours to obtain hyperbranched polysiloxane, whose structural formula is:

[0048]

[0049] In the formula, R is .

[0050] 2) Preparation of bisphenol A epoxy acrylate resin

[0051] Add 100g of bisphenol A epoxy resin (grade E44, epoxy value: 0.41-0.47) into a 250mL three-necked flask, stir and heat up to 95°C, then add 33g of acrylic acid and 0.02g of p-hydroxyanisole dropwise and 0.06g of triethylamine, the temperature was raised to 115° C. after the dropwise addition, and the reaction was carried out for 180 minutes to obtain bisphenol A epoxy acrylate resin.

[0052] 3) An epoxy acrylate for UV curable coatings

[0053] After 100 g of the bisphenol A epoxy acrylate resin prepared in step 2) of this example was cooled ...

Embodiment 3

[0055] 1) Preparation of hyperbranched polysiloxane

[0056] Pour vinyltriethoxysilane and deionized water into the reaction flask at a molar ratio of 1:1.5, adjust pH=2, N 2 protected, heated to 70°C for 3 hours, and dried in a vacuum oven for 3 hours to obtain hyperbranched polysiloxane. Its structural formula is referring to embodiment 1.

[0057] 2) Preparation of bisphenol A epoxy acrylate resin

[0058] Add 100g of bisphenol A type epoxy resin (grade E51) into a 250mL three-neck flask, stir and raise the temperature to 100°C, then add 16g of acrylic acid, 20g of methacrylic acid, 0.05g of hydroquinone and 0.1g of N , the mixed solution composed of N-dimethylbenzylamine was heated up to 110° C. after the dropwise addition, and reacted for 150 minutes to obtain bisphenol A epoxy acrylate resin.

[0059] 3) An epoxy acrylate for UV curable coatings

[0060] After 100 g of the bisphenol A epoxy acrylate resin prepared in step 2) of this example was cooled to 40°C, 20 g o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| epoxy value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com