Modified early strength agent

An early-strength agent and modification technology, applied in the field of concrete admixtures, can solve the problems of corrosion of steel bars, strength attenuation of cement paste, etc., and achieve the effects of improving early strength, early strength and late strength, and steric hindrance effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

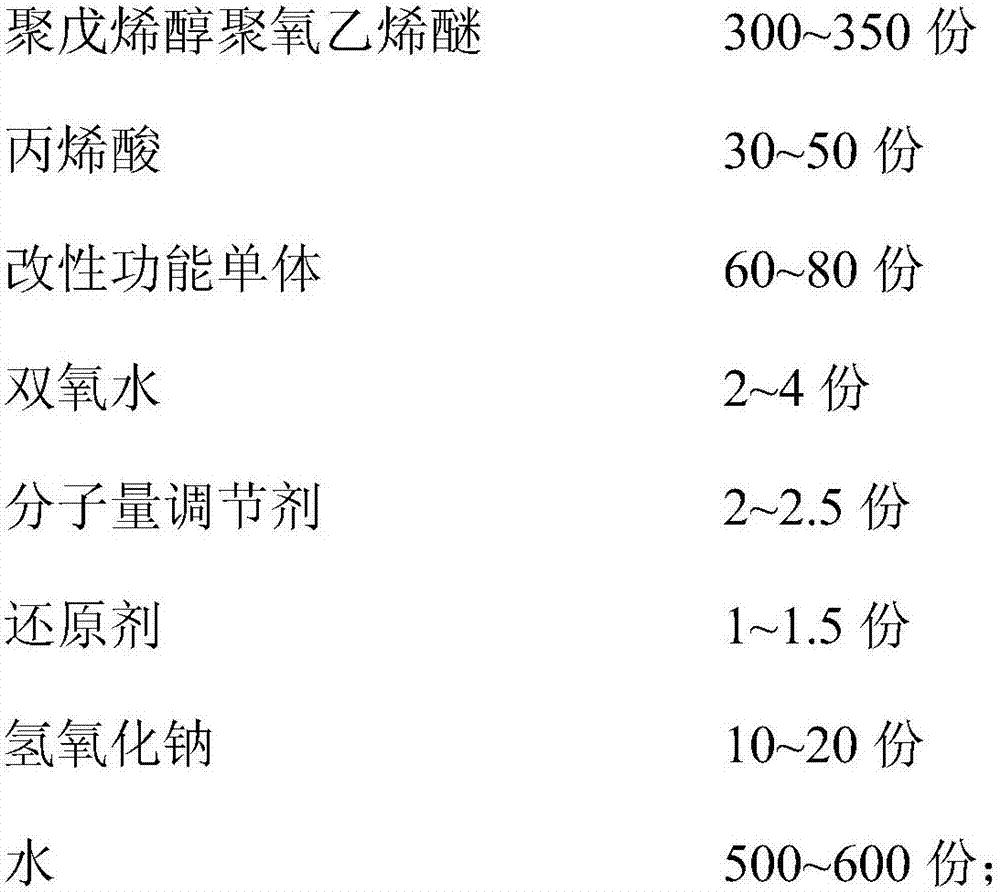

[0016] A modified early strength agent is made of the following raw materials in parts by weight:

[0017]

[0018] The modified functional monomer includes 17 parts of acrylamide, 10 parts of sodium dodecylbenzene sulfonate, 18 parts of sodium methallyl sulfonate and 22 parts of polyε-caprolactone diol.

[0019] The molecular weight regulator is mercaptopropionic acid. The addition of the molecular weight regulator is mainly to control the excessively large molecular weight and cause the molecular weight distribution to be too wide to prevent crosslinking.

[0020] The reducing agent is hang white block.

[0021] The mass percent concentration of hydrogen peroxide is 30%.

Embodiment 2

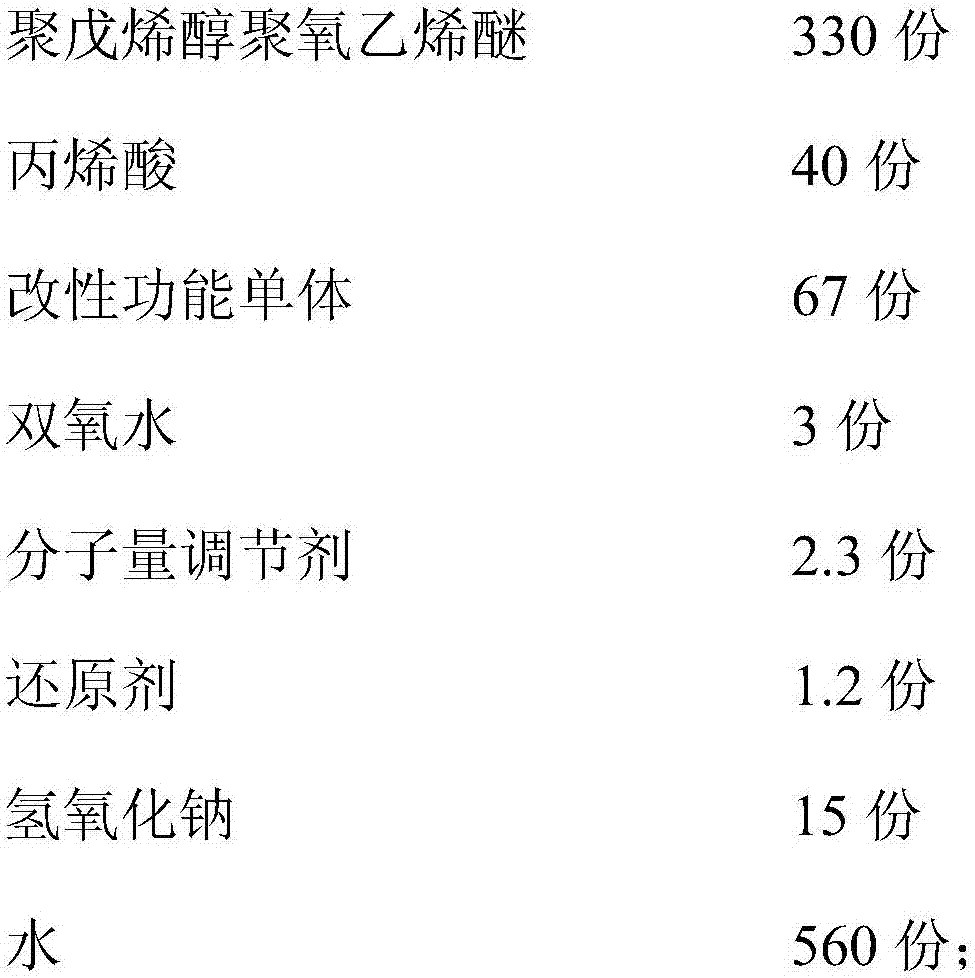

[0023] A modified early strength agent is made of the following raw materials in parts by weight:

[0024]

[0025]

[0026] The modified functional monomer includes 20 parts of acrylamide, 15 parts of sodium dodecylbenzenesulfonate, 20 parts of sodium methallylsulfonate and 25 parts of polyε-caprolactone diol.

[0027] The molecular weight regulator is mercaptopropionic acid. The addition of the molecular weight regulator is mainly to control the excessively large molecular weight and cause the molecular weight distribution to be too wide to prevent crosslinking.

[0028] The reducing agent is hang white block.

[0029] The mass percent concentration of hydrogen peroxide is 20%.

Embodiment 3

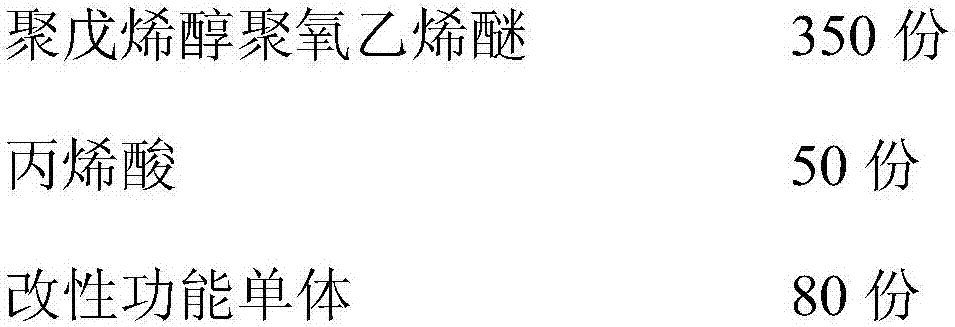

[0031] A modified early strength agent is made of the following raw materials in parts by weight:

[0032]

[0033] The modified functional monomer includes 15 parts of acrylamide, 10 parts of sodium dodecylbenzenesulfonate, 15 parts of sodium methallylsulfonate and 20 parts of polyε-caprolactone diol.

[0034] The molecular weight regulator is thioglycolic acid. The addition of the molecular weight regulator is mainly to control the excessively large molecular weight and cause the molecular weight distribution to be too wide to prevent crosslinking.

[0035] The reducing agent is L-ascorbic acid.

[0036] The mass percent concentration of hydrogen peroxide is 40%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com