Method for preparing Alite-barium calcium sulphoaluminate cement from red mud

A technology of barium calcium sulfoaluminate and cement, applied in the field of green building materials, can solve the problems of high cost and unsuitability for industrialized production, etc., and achieves the effects of low cost, improved flammability, and increased cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

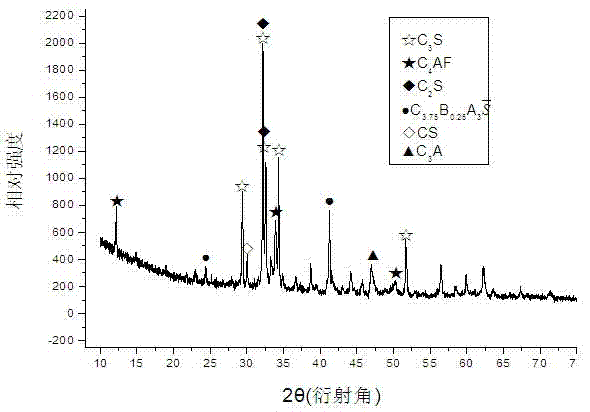

[0020] (1) The mass percentage of the mineral composition of the design cement clinker is: C 3.75 B 0.25 A 3 6%, C 2 S: 15%, C 3 S 60%, C 4 AF 11%, C 3 A 8%.

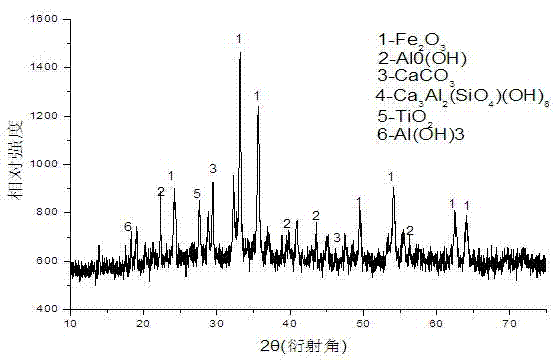

[0021] (2) The mass percentages of specific ingredients added are: 20.4% clay, 1.82% red mud, 72.5% limestone, 3.68% gypsum, 0.33% barium mud, 0.31% bauxite and 0.96% fluorite, of which fluorite is used as ore agent.

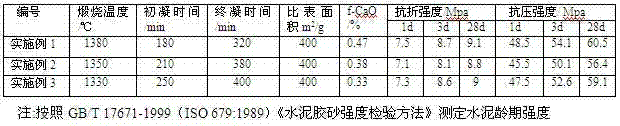

[0022](3) Crumble and homogenize the raw materials in step (2), dry until the moisture content is less than 1%, grind them through a 200-mesh sieve with a ball mill, and mix them evenly; The calcination temperature is 1380℃ for 1 hour, and the cooling method is rapid cooling.

[0023] (4) The material obtained in step (3) is crushed with a Y90L-4 crusher, the particle size is controlled at 1mm~3mm, and gypsum of 6% of the total mass of the obtained material is added, and then put into the SM2-100 vibration mill for powder Grind until the remaining 5% of the 200-mesh sieve reaches a specific su...

Embodiment 2

[0026] (1) The mass percentage of the mineral composition of the design cement clinker is: C 3.75 B 0.25 A 3 6%, C 2 S: 15%, C 3 S 55%, C 4 AF 16%, C 3 A 8%.

[0027] (2) The mass percentages of specific ingredients added are: 18.5% clay, 5.64% red mud, 70.3% limestone, 3.64% gypsum, 0.33% barium mud, 0.63% bauxite and 0.96% fluorite; agent.

[0028] (3) Crumble and homogenize the raw materials in step (2), dry until the moisture content is less than 1%, grind them through a 200-mesh sieve with a ball mill, and mix them evenly; The calcination temperature is 1350℃ for 1 hour, and the cooling method is rapid cooling.

[0029] (4) The material obtained in step (3) is crushed with a Y90L-4 crusher, the particle size is controlled at 1mm~3mm, and 8% of the total mass of the obtained material is added to the gypsum, and then put into the SM2-100 vibration mill for powder Grind until the remaining 5% of the 200-mesh sieve reaches a specific surface area of 400m 2 / kg,...

Embodiment 3

[0032] (1) The mass percentage of the mineral composition of the design cement clinker is: C 3.75 B 0.25 A 3 6%, C 2 S: 19%, C 3 S 50%, C 4 AF 20% and C 3 A 8%.

[0033] (2) The mass percentages of specific ingredients added are: 18.2% clay, 8.4% red mud, 68.1% limestone, 3.6% gypsum, 0.32% barium mud, 0.42% bauxite and 0.96% fluorite; agent.

[0034] (3) Crumble and homogenize the raw materials in step (2), dry until the moisture content is less than 1%, grind them through a 200-mesh sieve with a ball mill, and mix them evenly; The calcination temperature is 1330℃ for 1 hour, and the cooling method is rapid cooling.

[0035] (4) The material obtained in step (3) is crushed with a Y90L-4 crusher, the particle size is controlled at 1mm~3mm, and dihydrate gypsum powder with 8% of the total mass of the obtained material is added, and then put into SM2-100 vibration Grind in the mill until the remaining 5% of the sieve passes through a 200-mesh sieve to a specific surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com