A kind of Portland cement clinker and preparation method thereof

A portland cement and clinker technology, applied in the field of Portland cement clinker, the Portland cement clinker preparation field, can solve the problems of blank theoretical research, etc., achieve strong universality, increase production cost, and facilitate The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

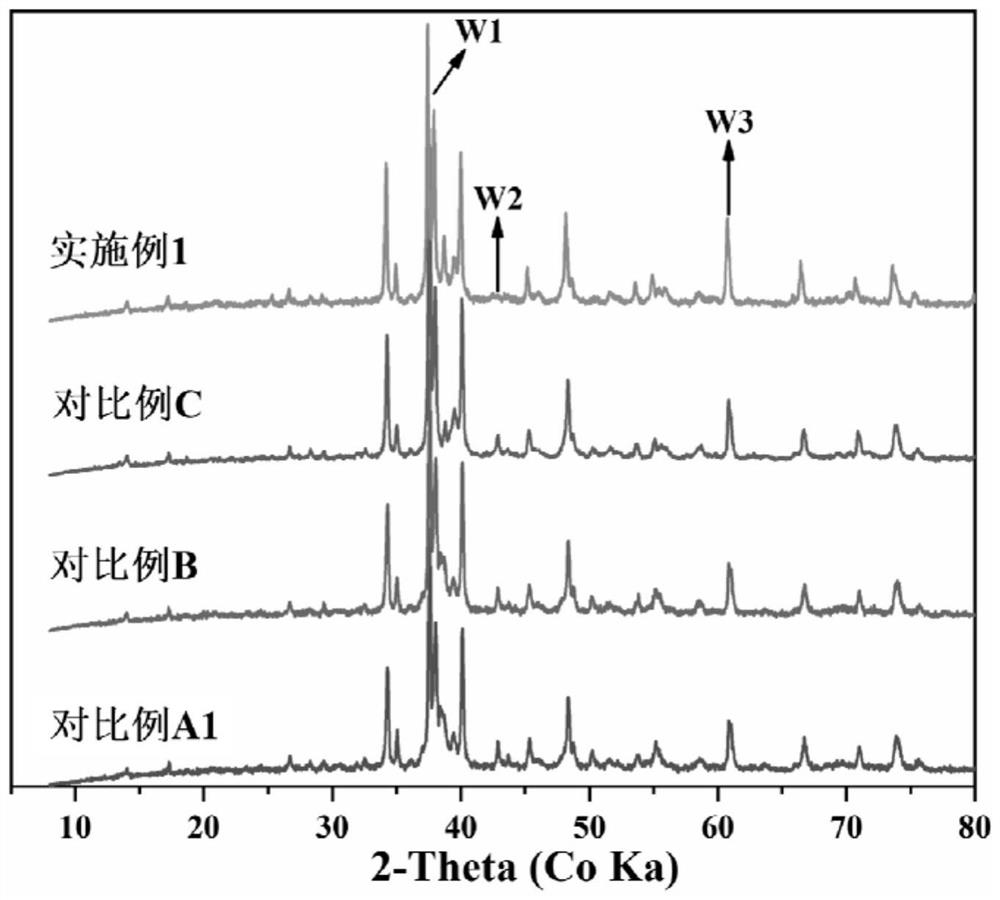

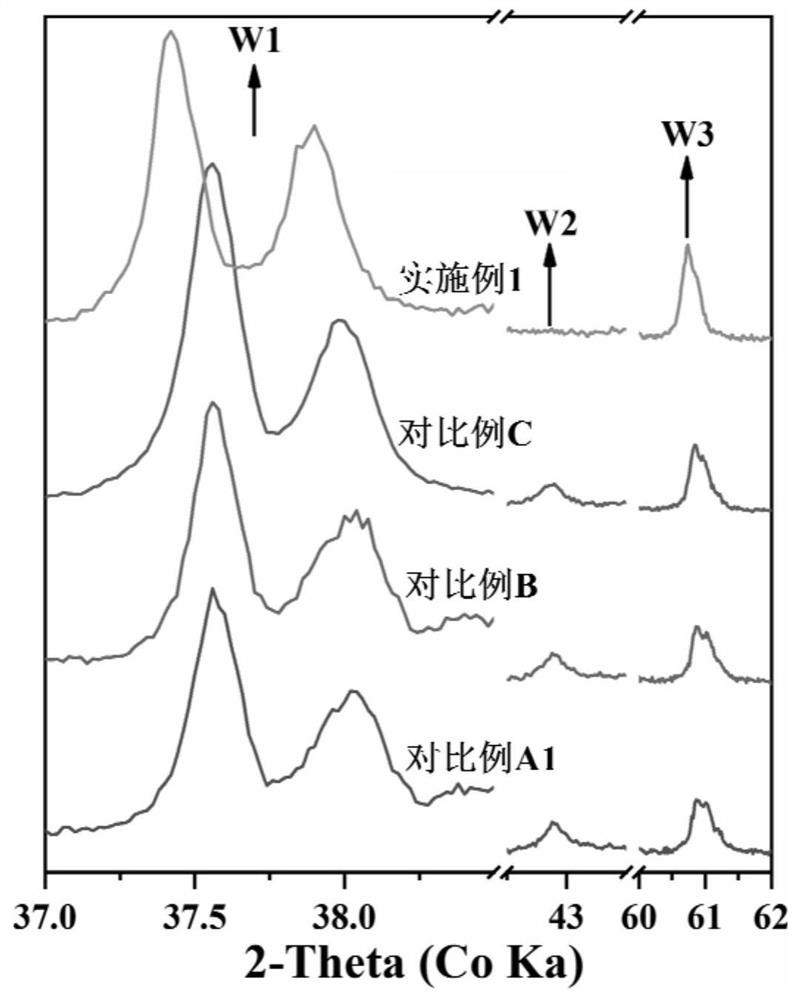

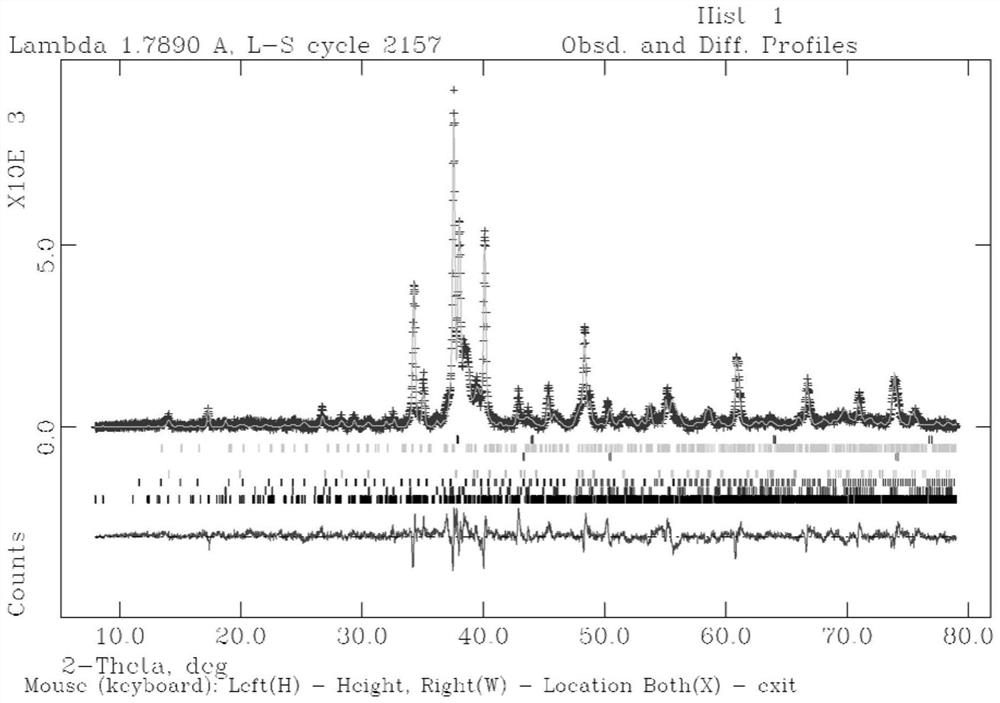

[0065] Using analytically pure CaCO 3 , SiO 2 , Al 2 o 3 , Fe 2 o 3 , MgO and desulfurized gypsum for raw meal configuration, the design clinker mineral composition is C 3 S 63.42%, C 2 S 17.70%, C 3 A 8.6%, C 4 AF 10.28%, design clinker rate value KH=0.91, SM=2.60, IM=1.60. The clinker MgO content is 0.5% in the embodiment 1, SO 3 Incorporated in the form of desulfurized gypsum, SO in clinker 3 The content is 0.36%. As a comparison A1 does not contain magnesium and sulfur in the clinker, as a comparison B contains sulfur in the clinker but does not contain magnesium, as a comparison C contains magnesium but does not contain sulfur in the clinker. The raw material is mixed according to the raw material ratio and mixed evenly, then the mixed raw material is calcined, the temperature is raised at 10°C / min during the calcining stage, the temperature is raised to 1500°C, kept for 1 hour, and then cooled at a cooling rate of 60°C / min to room temperature (generally 15-40...

Embodiment 2

[0077] Using analytically pure CaCO 3 , SiO 2 , Al 2 o 3 , Fe 2 o 3 , MgO and desulfurized gypsum for raw meal configuration, the design clinker mineral composition is C 3 S 63.42%, C 2 S 17.70%, C 3 A 8.6%, C 4 AF 10.28%, design clinker rate value KH=0.91, SM=2.60, IM=1.60. The clinker MgO content is 1.5% in embodiment 2, SO 3 Incorporated in the form of desulfurized gypsum, SO in clinker 3The content is 1.09. The comparative A2 contains no magnesium and sulfur in the clinker, the comparative D contains magnesium but no sulfur in the clinker, and the comparative E contains sulfur but no magnesium in the clinker. The raw material is mixed according to the raw material ratio and mixed evenly, then the mixed raw material is calcined, the temperature is raised at 10°C / min during the calcining stage, the temperature is raised to 1500°C, kept for 1 hour, and then cooled at a cooling rate of 60°C / min to room temperature (generally 15-40°C), the fired clinker is ground to...

Embodiment 3

[0089] Using analytically pure CaCO 3 , SiO 2 , Al 2 o 3 , Fe 2 o 3 , MgO and desulfurized gypsum for raw meal configuration, the design clinker mineral composition is C 3 S 63.42%, C 2 S 17.70%, C 3 A 8.6%, C 4 AF 10.28%, design clinker rate value KH=0.91, SM=2.60, IM=1.60. The clinker MgO content is 3.0% in embodiment 3, SO 3 Incorporated in the form of desulfurized gypsum, SO in clinker 3 The content is 2.18%. The comparative A3 contains no magnesium and sulfur in the clinker, the comparative F contains magnesium but no sulfur in the clinker, and the comparative G contains sulfur but no magnesium in the clinker. The raw material is mixed according to the raw material ratio and mixed evenly, then the mixed raw material is calcined, the temperature is raised at 10°C / min during the calcining stage, the temperature is raised to 1500°C, kept for 1 hour, and then cooled at a cooling rate of 60°C / min to room temperature (generally 15-40°C), the fired clinker is ground ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com