Anti-erosion refractory castable for waste medical incinerator lining and preparation method of anti-erosion refractory castable

A refractory castable and anti-erosion technology, which is applied in the field of refractory castable production, can solve the problems of poor corrosion resistance of refractory castables, and achieve the effect of strong anti-corrosion effect and small erosion area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

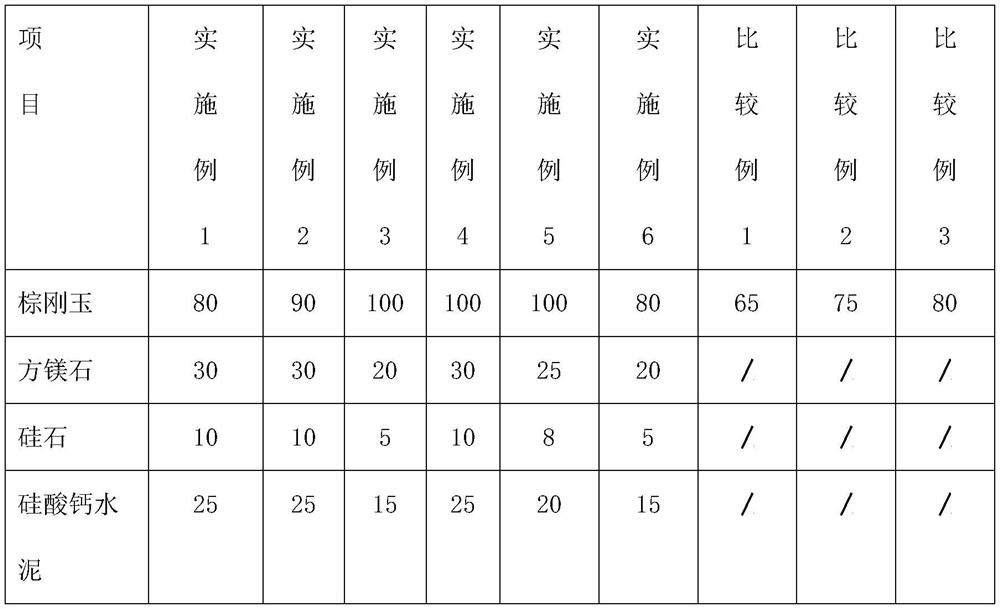

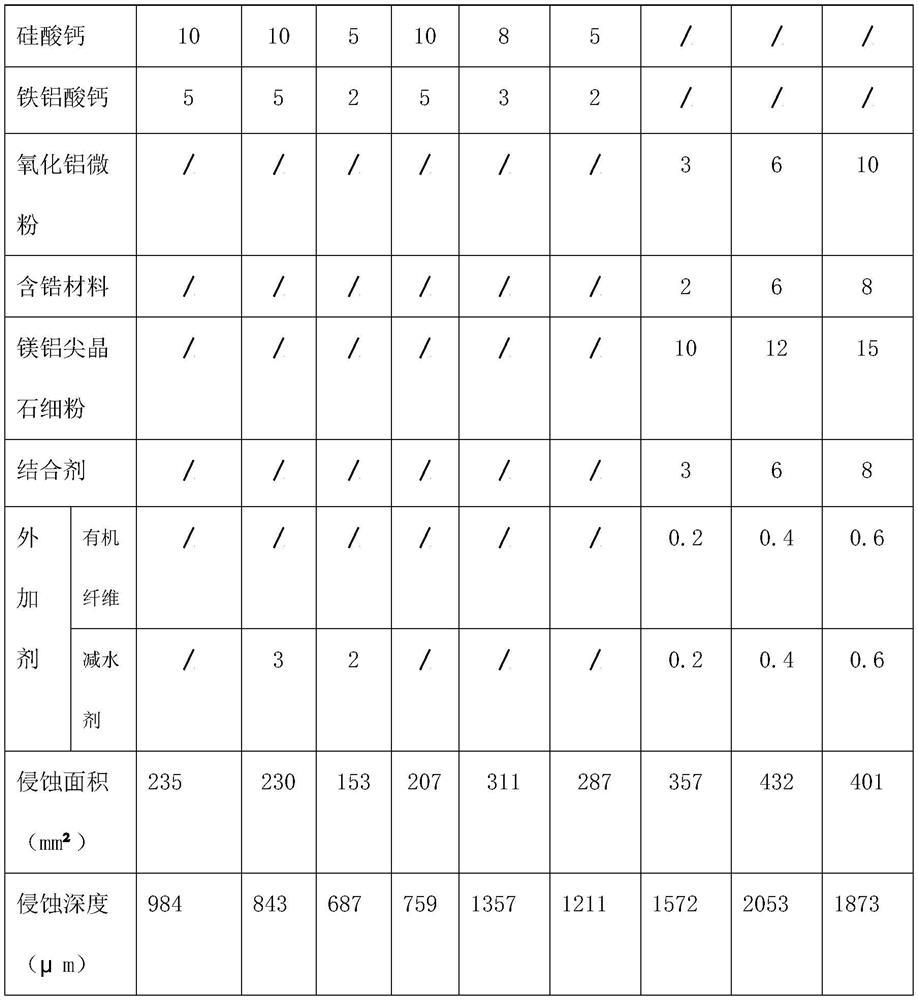

Examples

Embodiment 1

[0018] An anti-corrosion refractory castable for waste medical incinerator lining and its preparation method, comprising the following raw materials in parts by weight: 80 parts of brown corundum, 30 parts of periclase, 10 parts of silica, 25 parts of calcium silicate cement, calcium silicate 10 parts, 5 parts of calcium aluminoferrite, 3 parts of admixture, according to the weight ratio, firstly crush brown corundum, periclase, silica, calcium silicate and calcium aluminoferrite into powders and then mix them uniformly to obtain Refractory castables.

[0019] After the brown corundum is crushed, sieve and select the brown corundum with a particle size of 200-700 μm.

[0020] After the periclase is crushed, sieve and select the periclase with a particle size of 100-200 μm.

[0021] After the silica is crushed, sieve and select the silica with a particle size of 700-900 μm.

[0022] The powder of brown corundum, periclase, silica, calcium silicate and calcium aluminoferrite m...

Embodiment 2

[0026] An anti-corrosion refractory castable for the lining of waste medical incinerators and its preparation method, comprising the following raw materials in parts by weight: 90 parts of brown corundum, 30 parts of periclase, 10 parts of silica, 25 parts of calcium silicate cement, calcium silicate 10 parts, 5 parts of calcium aluminoferrite, 3 parts of admixture, according to the weight ratio, firstly crush brown corundum, periclase, silica, calcium silicate and calcium aluminoferrite into powders and then mix them uniformly to obtain Refractory castables.

[0027] After the brown corundum is crushed, sieve and select the brown corundum with a particle size of 200-700 μm.

[0028] After the periclase is crushed, sieve and select the periclase with a particle size of 100-200 μm.

[0029] After the silica is crushed, sieve and select the silica with a particle size of 700-900 μm.

[0030] The powder mixed with the brown corundum, periclase, silica, calcium silicate and calc...

Embodiment 3

[0034] An anti-corrosion refractory castable for the lining of waste medical incinerators and its preparation method, comprising the following raw materials in parts by weight: 100 parts of brown corundum, 20 parts of periclase, 5 parts of silica, 15 parts of calcium silicate cement, calcium silicate 5 parts, 2 parts of calcium aluminoferrite, 2 parts of admixture, according to the weight ratio, first crush brown corundum, periclase, silica, calcium silicate and calcium aluminoferrite into powders and then mix them uniformly to obtain Refractory castables.

[0035] After the brown corundum is crushed, sieve and select the brown corundum with a particle size of 200-700 μm.

[0036] After the periclase is crushed, sieve and select the periclase with a particle size of 100-200 μm.

[0037] After the silica is crushed, sieve and select the silica with a particle size of 700-900 μm.

[0038] The powder mixed with the brown corundum, periclase, silica, calcium silicate and calcium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com