High belite-containing sulfoaluminous clinker, method for the production and the use thereof for preparing hydraulic binders

A technology of sulfoaluminate clinker and hydraulic glue, applied in cement production, climate sustainability, sustainable waste treatment, etc., can solve problems such as instability of calcium sulfate, and achieve the goal of reducing CO2 industrial emissions and energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

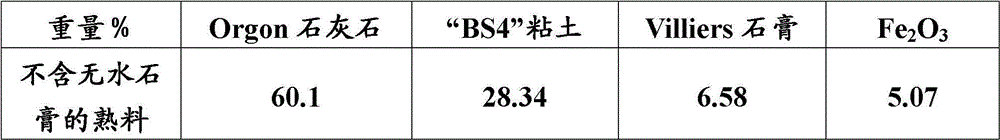

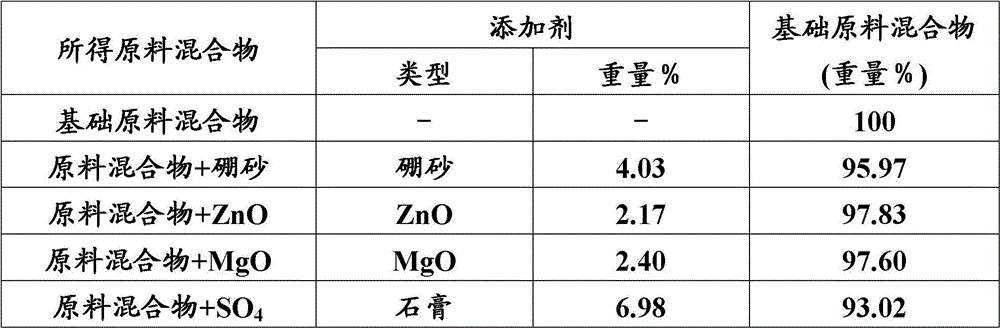

[0103] Embodiment 1: Preparation of raw material mixture of sulphoaluminate clinker

[0104] For the manufacture of the sulphoaluminate clinker of the invention, the raw materials used are selected from Orgon limestone sold by MEAC, brand alumina-rich clay and / or the less alumina-rich clay sold by AGS-BMP Brand clay and crushed natural plaster from Villiers. A small amount of iron oxide or iron ore as shown in Table 3 was also used to adjust the ferrite phase content of the clinker.

[0105] The chemical formulations of the raw materials used are listed in Table 2.

[0106] Table 2

[0107] % CaO SiO 2 Al 2 o 3 Fe 2 o 3 SO 3 MgO TiO 2 K 2 o Na 2 o Loss on ignition Orgon fine grain 55.71 0.01 0.08 0.03 0.05 0.19 0.01 0.01 0.01 43.67 BS4 clay 0.14 41.88 40.26 0.66 0.34 0.08 0.87 0.16 0.12 16.03 BS5 clay 0.38 51.04 32.78 1.30 0.20 0.18 1.3...

Embodiment 2

[0120] Embodiment 2: the preparation of sulfoaluminate clinker

[0121] 250 grams of the raw material mixture from Table 4 were placed in a crucible with a diameter of 7 cm and a height of 10 cm.

[0122] The crucible is first brought to a pre-calcination temperature of 950 to 975°C with a ramp rate of approximately 15°C / min. The raw material mixture was precalcined for 30 minutes.

[0123] Then, the crucible was quickly transferred to a high-temperature furnace previously heated to 950 to 975°C.

[0124] The crucible thus transferred was allowed to reach thermal equilibrium at 950 to 975°C, then the temperature was increased at 5°C / min until it reached a temperature of 1150 to 1350°C over a period of 30 to 60 minutes.

[0125] After the firing time, the clinker thus obtained was cooled open until it reached ambient temperature.

[0126] As shown in Table 5, compared with ordinary Portland cement, CO 2 The reduction in emissions is greater than 25%.

[0127] table 5

[...

Embodiment 3

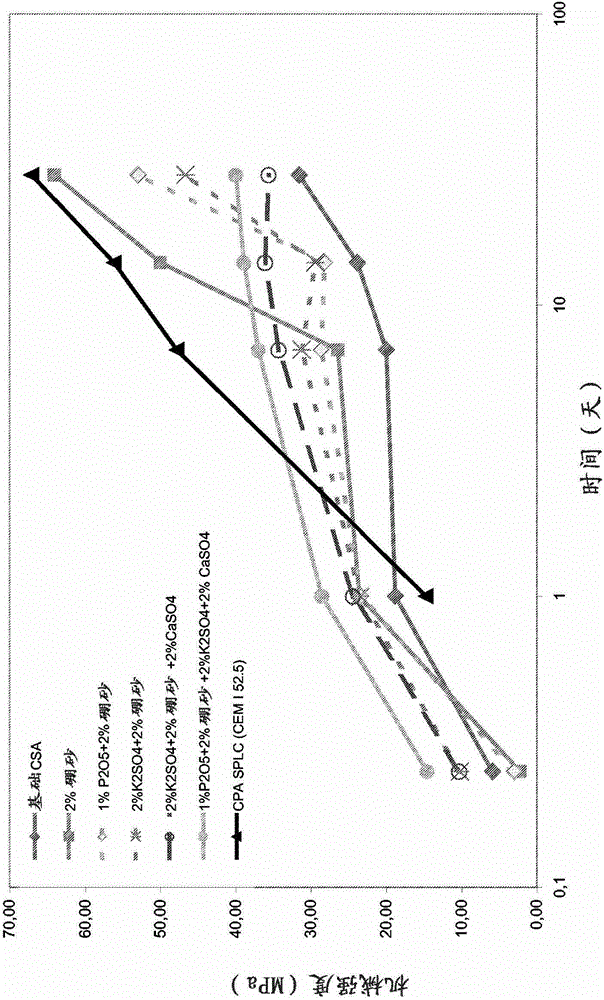

[0130] Example 3: Sulphoaluminate cement

[0131] The cements corresponding to the different clinkers were obtained by co-grinding with 8% gypsum as a setting regulator using a laboratory grinder with a capacity of 1 kg, but the raw material mixture in Table 4 + SO 4 The exception is the corresponding clinker, which already contains the required amount of gypsum.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com