Hot-melting connection assembly and connecting method thereof

A technology for connecting components and connecting methods, which is applied in the direction of pipeline connection arrangement, pipe/pipe joint/pipe fitting, mechanical equipment, etc., which can solve the problems of increased difficulty in installation and transportation, poor firmness, difficult bending and forming, etc., and achieve reduction Failure rate, avoid duplication of production, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

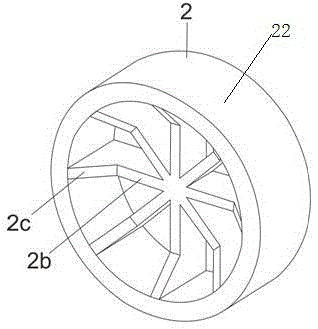

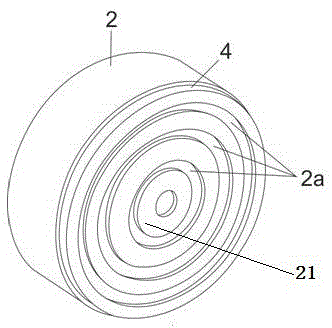

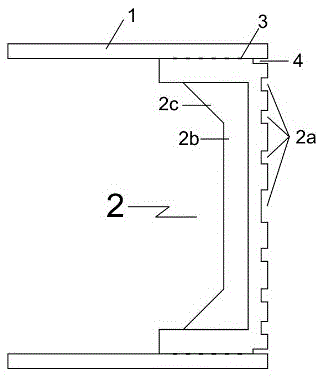

[0045] see Figure 1A , 1B , a hot-melt connection assembly, the connection assembly includes a connection assembly body and an additional assembly arranged on the connection assembly body, the connection assembly body is set in a circular shape, since the pipes in the prior art are all circular, in order To connect two adjacent pipes more tightly and reliably, the shape of the connection assembly also needs to be set to a circle. In this embodiment, the body of the connection assembly is set to be cylindrical, and the cylindrical body of the connection assembly includes Tube bottom 21 and tube body 22, described tube bottom 21 is arranged on one end of tube body 22, and the other end is open shape, from Figure 1A It can be seen from the figure that the shape of the connection assembly is similar to a bowl-shaped structure, with a bottom seal at one end and an opening at the other end. The additional assembly includes a support frame, which is set on the inner surface of the...

Embodiment 2

[0048] see Figure 3A , 3B , a hot-melt connection assembly, the connection assembly includes a connection assembly body and an additional assembly arranged on the connection assembly body, the connection assembly body is set in a circular shape, since the pipes in the prior art are all circular, in order To connect two adjacent pipes more tightly and reliably, the shape of the connection assembly also needs to be set to a circle. In this embodiment, the body of the connection assembly is set to be cylindrical, and the cylindrical body of the connection assembly includes Tube bottom 21 and tube body 22, described tube bottom 21 is arranged on one end of tube body 22, and the other end is open shape, from Figure 3A It can be seen from the figure that the shape of the connection assembly is similar to a bowl-shaped structure, with a bottom seal at one end and an opening at the other end. In this embodiment, the additional assembly includes a central shaft 2f, and the central s...

Embodiment 3

[0051] see Figure 5 , Figure 6A , 6B , a hot-melt connection assembly, the connection assembly includes a connection assembly body and an additional assembly arranged on the connection assembly body, the connection assembly body is set in a circular shape, since the pipes in the prior art are all circular, in order To connect two adjacent pipes more tightly and reliably, the shape of the connection assembly also needs to be set to a circle. In this embodiment, the body of the connection assembly is set to a ring shape, and the attachment assembly includes side grooves 4 and An inclined edge 7, wherein the outer side of one end of the circular connection body is provided with a side groove 4, and the other end is provided with an inclined edge 7, see Figure 6A , the cross-section of the circular connecting assembly body is a right-angled trapezoid, with the right-angled side facing outwards and the inclined side facing inward, wherein the groove is also arranged at the con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com