Methanol synthesis system and methanol synthesis method

A technology of methanol synthesis and synthesis tower, which is applied in chemical instruments and methods, preparation of hydroxyl compounds, and preparation of organic compounds, etc. It can solve the problems of waste, exhaust gas residual pressure and waste heat not collected and utilized, and low single-pass conversion rate. Achieve the effect of reducing energy waste and industrial emissions, improving the total carbon conversion rate, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

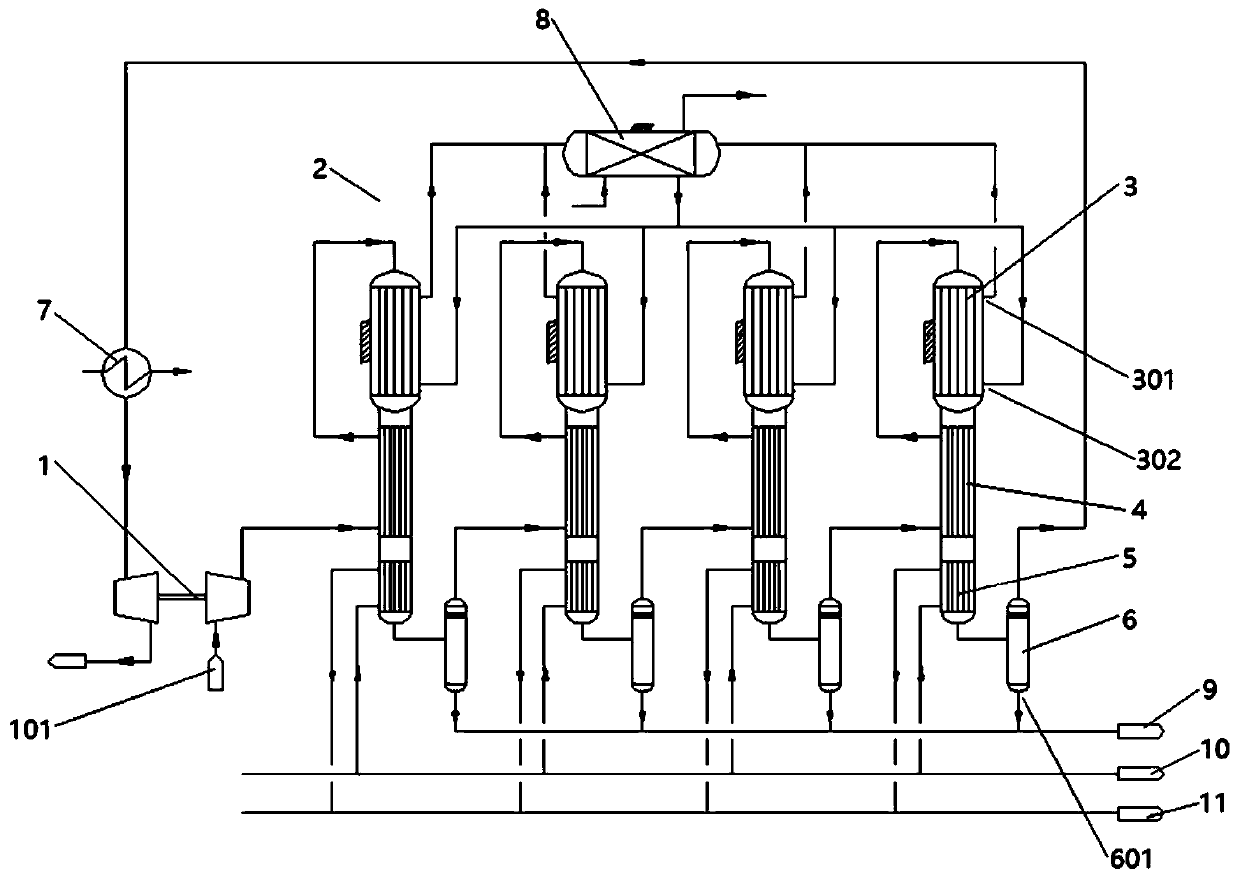

[0042] The embodiment of the present invention also provides a methanol synthesis method, the methanol synthesis method comprises the following steps:

[0043] S100: The raw material gas pressurized by the booster expander 1 enters the multi-stage methanol synthesis unit 2, and utilizes the heat of the reaction gas flowing through the gas-gas heat exchanger 4 of the first-stage methanol synthesis unit to convert the raw material gas to warm up.

[0044] It can be understood that the gas-gas heat exchanger 4 is used to preheat the raw material gas pressurized by the booster expander 1, for example, after the gas-gas heat exchanger 4 preheats the raw material gas to 200°C to 230°C Then enter the synthesis tower 3 for reaction, and the reacted reaction gas enters the gas-gas heat exchanger 4 and can be used as a heat source for preheating the above-mentioned raw material gas.

[0045] S200: The preheated raw material gas enters the synthesis tower 3 through the tube side of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com