Crosshead two-stroke low-speed diesel engine deceleration propulsion device

A cross-head type, propulsion device technology, applied in mechanical gear transmission and other directions, can solve problems such as unfavorable energy saving and environmental protection manufacturing, and achieve the effects of saving raw material costs, reducing vibration, and reducing volume and weight.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The utility model is described in further detail below in conjunction with the accompanying drawings.

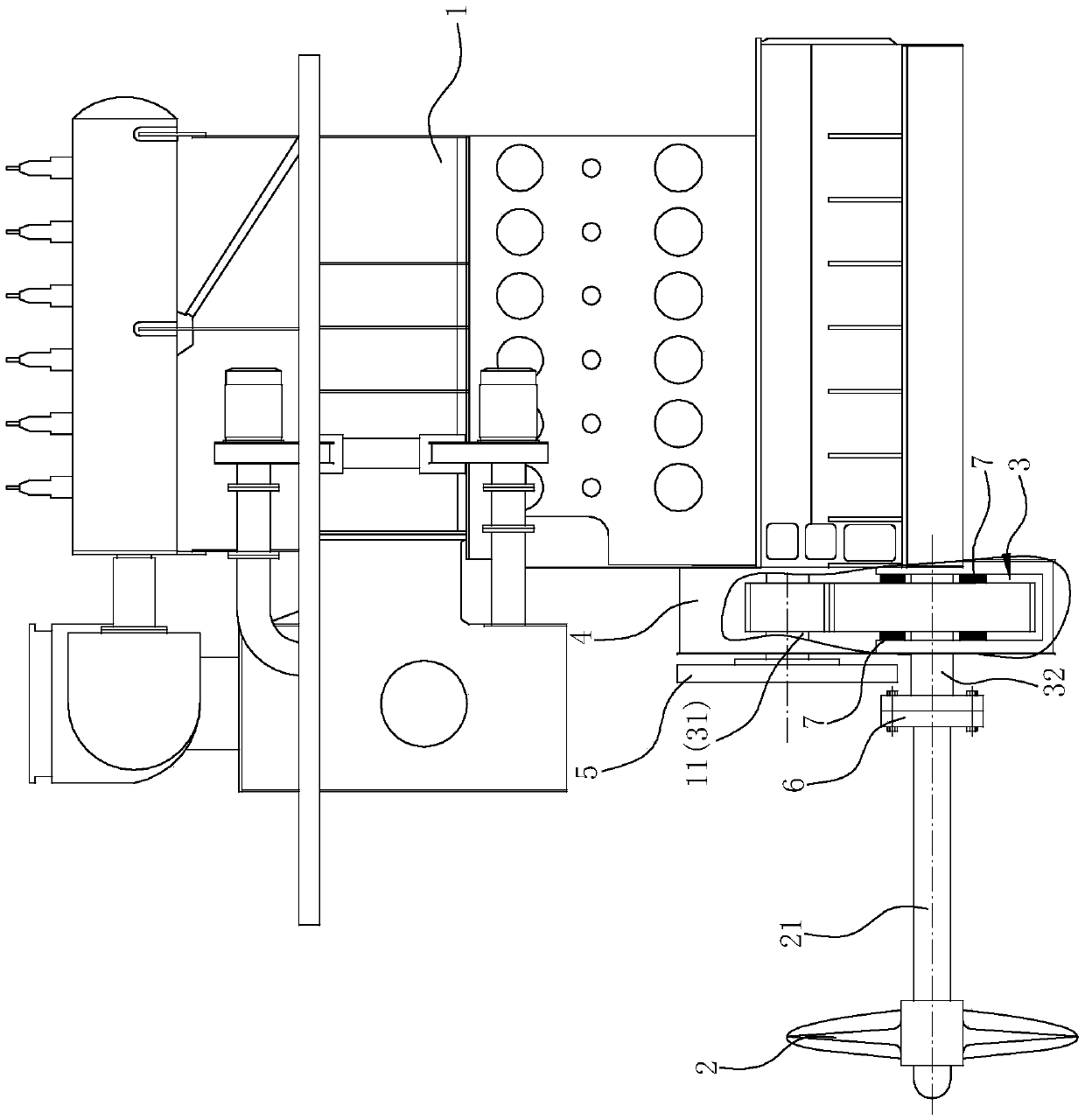

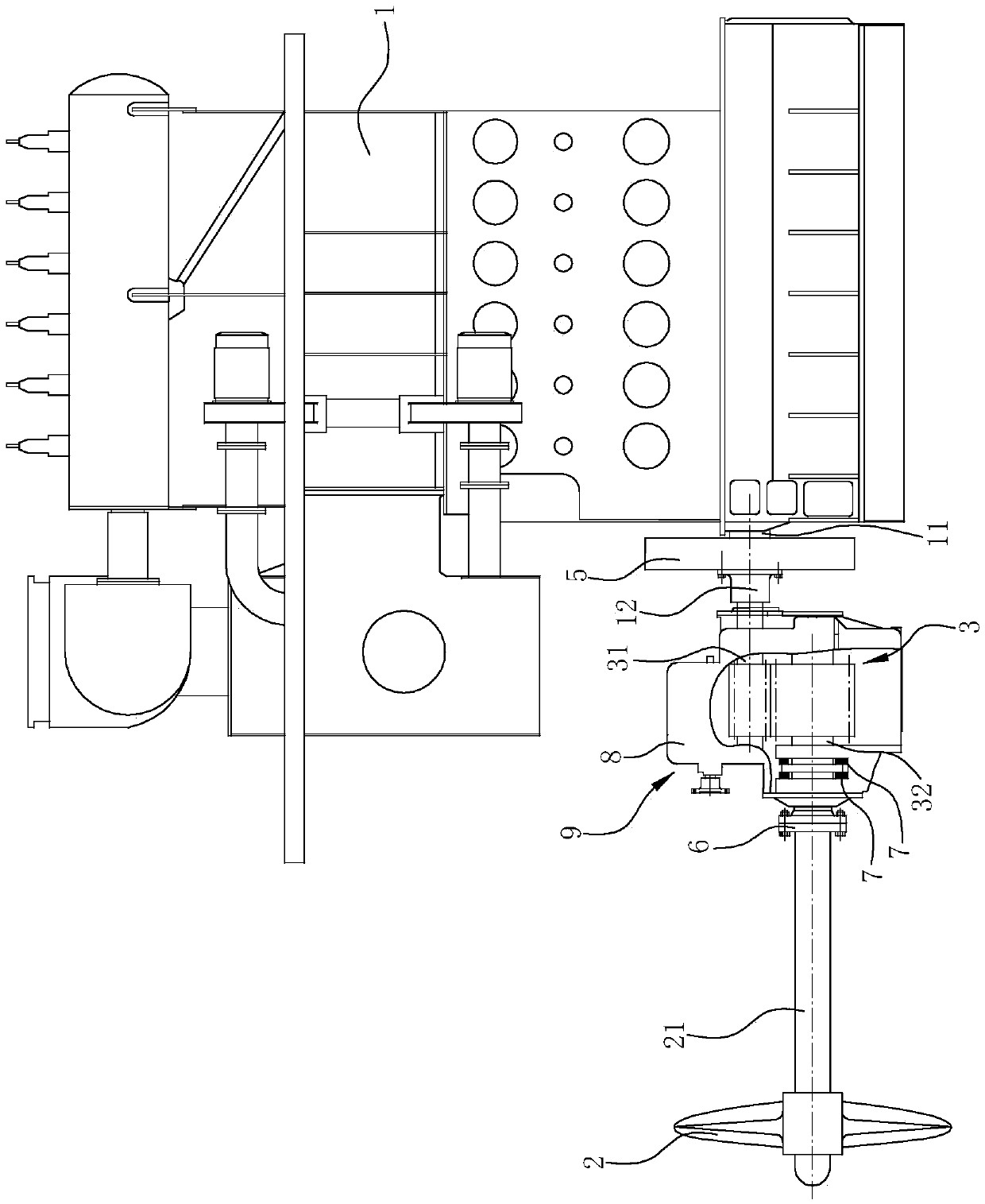

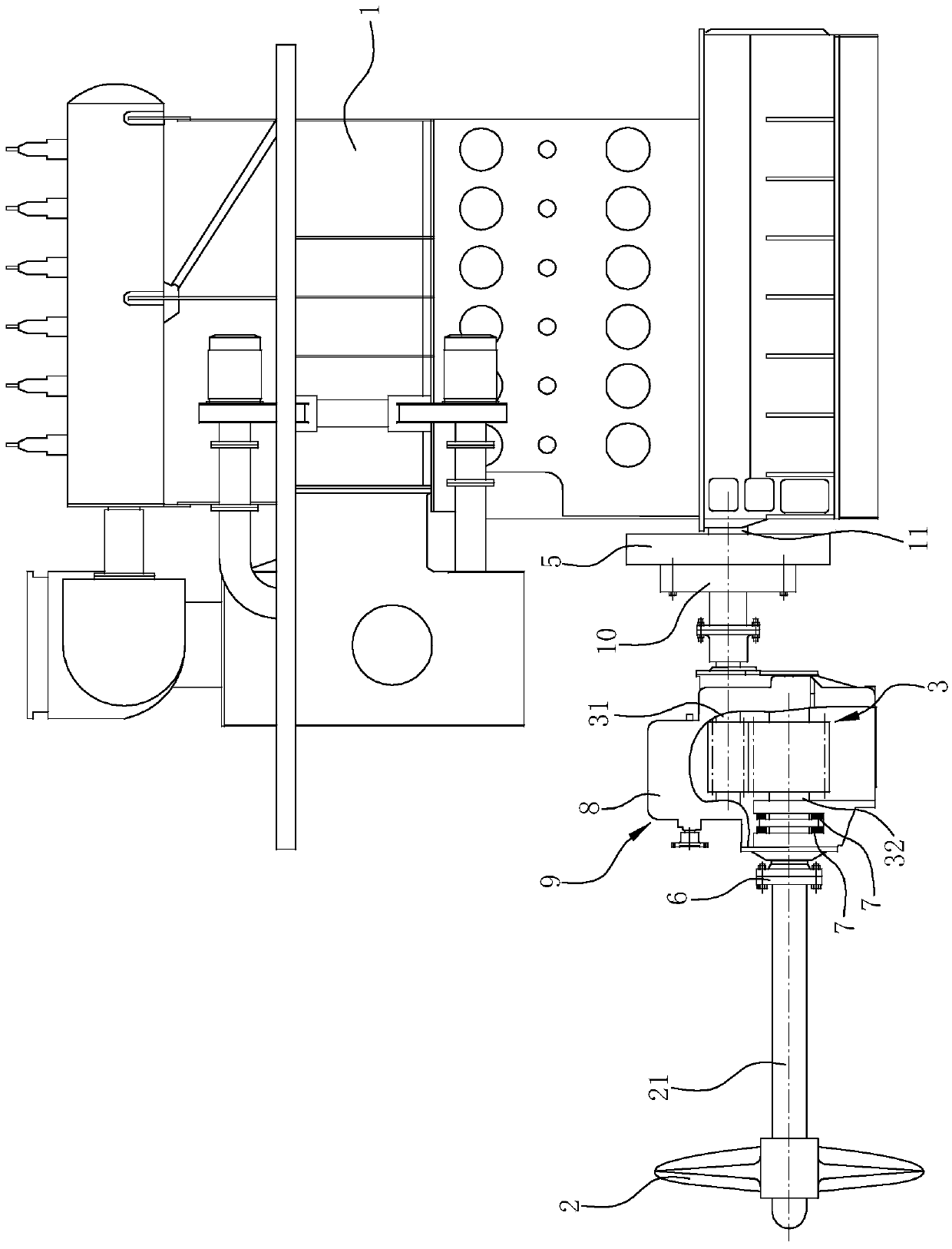

[0019] Such as figure 1 Shown is the first embodiment of the present invention.

[0020] A crosshead type two-stroke low-speed diesel engine deceleration propulsion device, comprising a crosshead type two-stroke low-speed diesel engine 1 and a propeller 2, the output shaft 11 of the crosshead type two-stroke low-speed diesel engine 1 passes through the reduction gear set 3 and the tail shaft 21 of the propeller 2 Connect to reduce the RPM of propeller 2.

[0021] The reduction gear set 3 in this embodiment is installed in the base box 4 at the rear of the diesel engine base, and the output shaft 11 of the crosshead type two-stroke low-speed diesel engine is used as the pinion rotating shaft 31 of the reduction gear set 3, while the crosshead type two-stroke After the output shaft 11 of the stroke low-speed diesel engine passes through the base box 4, a flywheel 5 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com