Polyacrylic ester polymer cement-based waterproof paint and preparation method thereof

A polyacrylate, waterproof coating technology, applied in the field of cement-based waterproof coatings, can solve the problems of long condensation and curing time of the coating film, reduced structural strength and peel strength, shortened curing time, etc. Compatibility, the effect of improving compatibility and structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

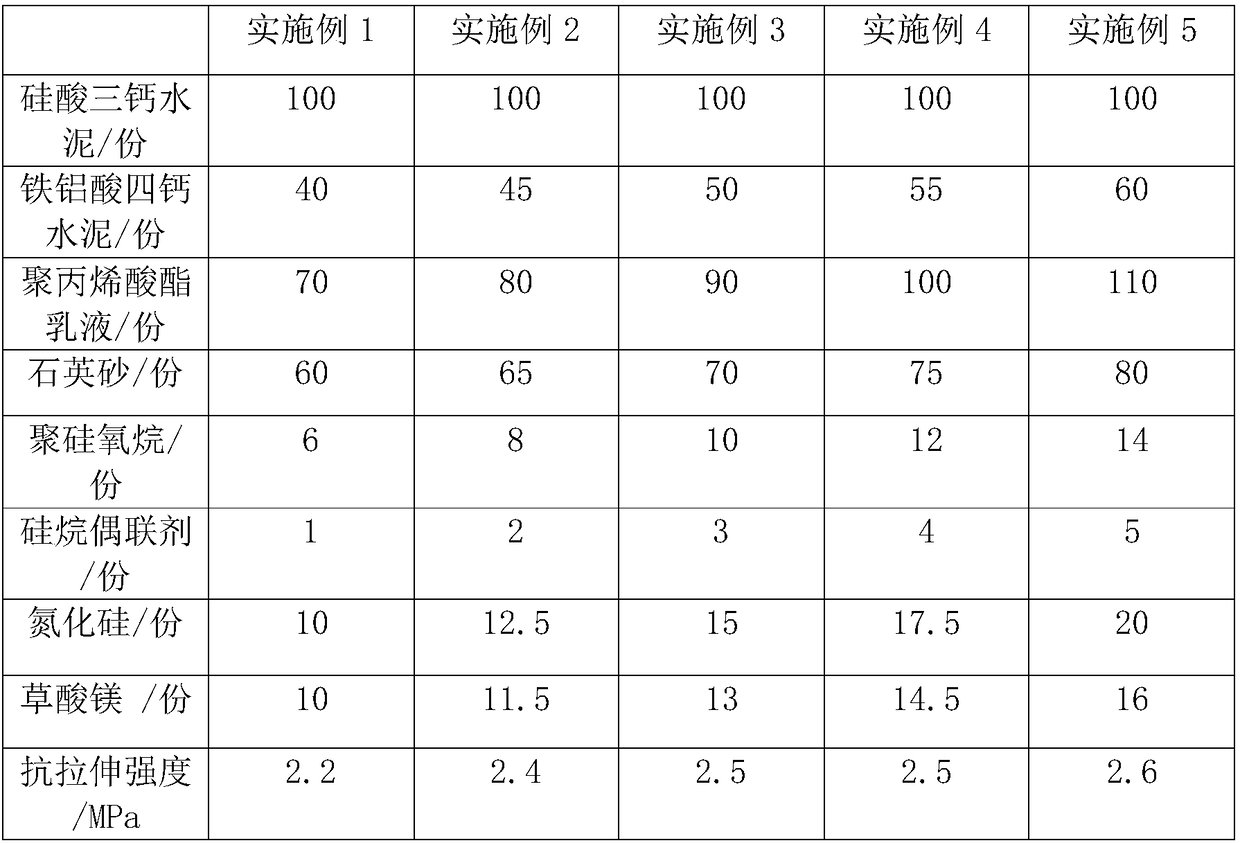

Examples

Embodiment Construction

[0013] Below in conjunction with embodiment, the present invention is described in further detail, so that those skilled in the art can implement according to referring to description text.

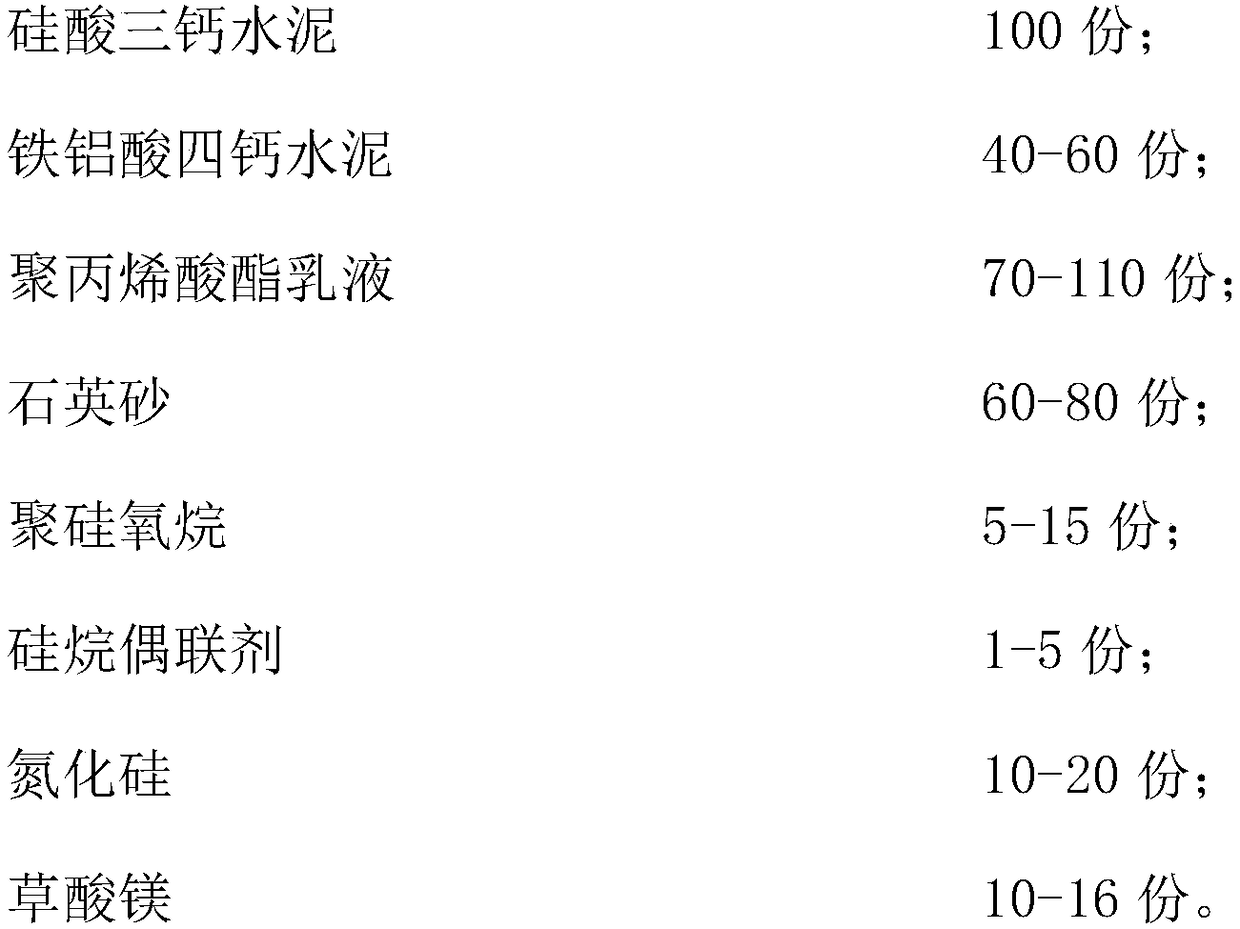

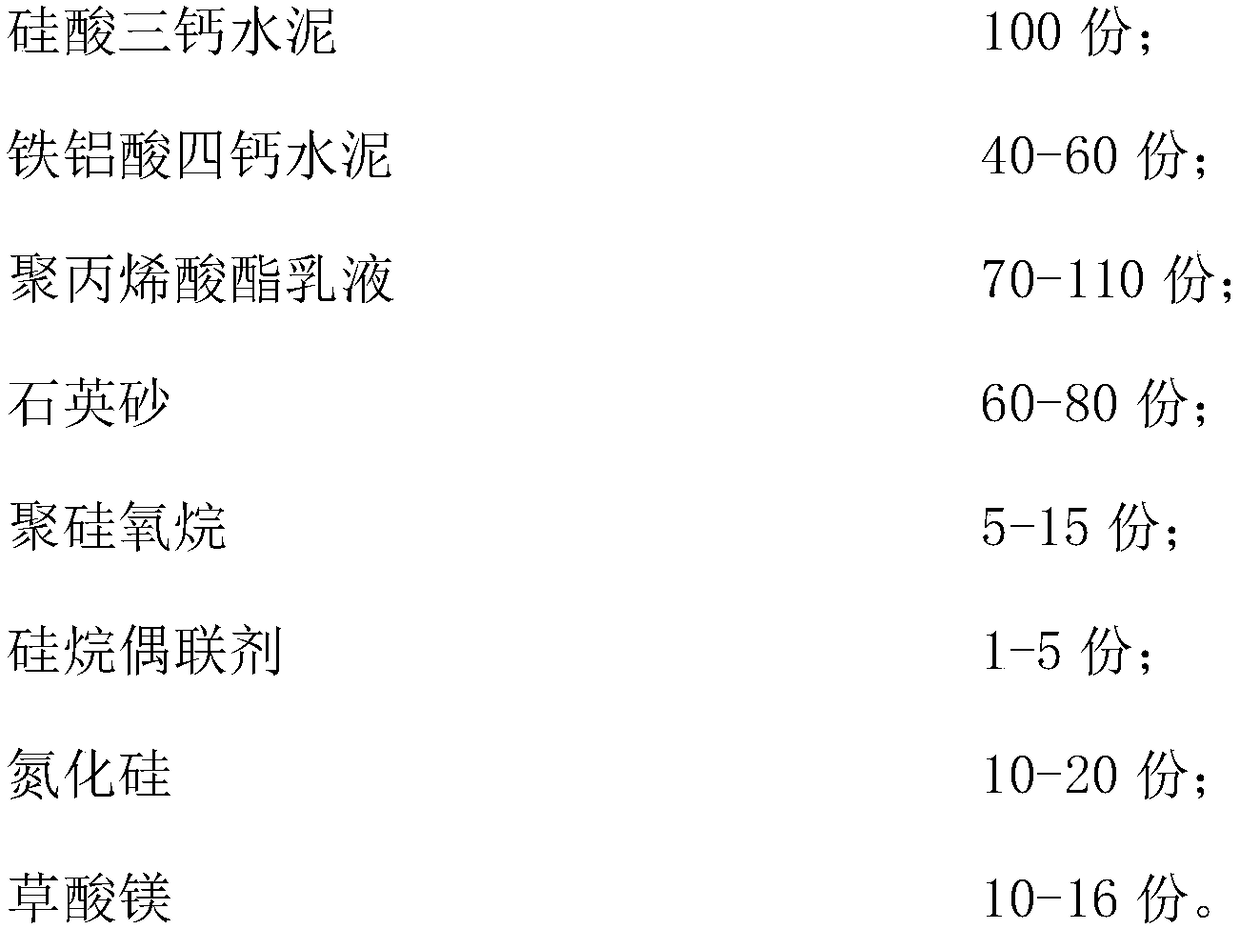

[0014] The present invention proposes the polyacrylate polymer cement-based waterproof coating of an embodiment, comprising following components by weight:

[0015]

[0016] The present invention uses tricalcium silicate cement as the gelling base material, which can absorb the moisture in the polyacrylate emulsion, and rapidly hydrates into calcium silicate gel at room temperature. Compared with dicalcium silicate cement, the hydration reaction is faster Strong, saves the drying and solidification time of waterproof coatings, and although the curing strength is high, its hydration reaction equation is as follows: 3CaO·SiO 2 +nH O =xCaO·SiO 2 ·yH 2 O+(3-x)Ca(OH) 2 , x represents the ratio of calcium to silicon, n represents the amount of bound water, and y represents the number of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com