Shale gas horizontal well cementating cement and shale gas horizontal well cementating cement paste

A technology for cementing cement slurry and shale gas, which is applied to the field of cementing cement for shale gas horizontal wells and cementing slurry for shale gas horizontal wells, and can solve structural instability, insufficient long-term durability of cementing cement sheath, Affecting oil and gas well oil recovery and other issues, to achieve the effect of reducing maintenance, good economic and social benefits, market prospects and broad potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] For further elaborating the technical means and effects that the present invention takes to reach the intended invention purpose, the shale gas horizontal well cementing cement and the shale gas horizontal well cementing cement slurry proposed according to the present invention will be described below in conjunction with the preferred embodiments. Its specific implementation, structure, feature and effect thereof are described in detail as follows. In the following description, different "one embodiment" or "embodiment" do not necessarily refer to the same embodiment. Furthermore, the particular features, structures, or characteristics of one or more embodiments may be combined in any suitable manner.

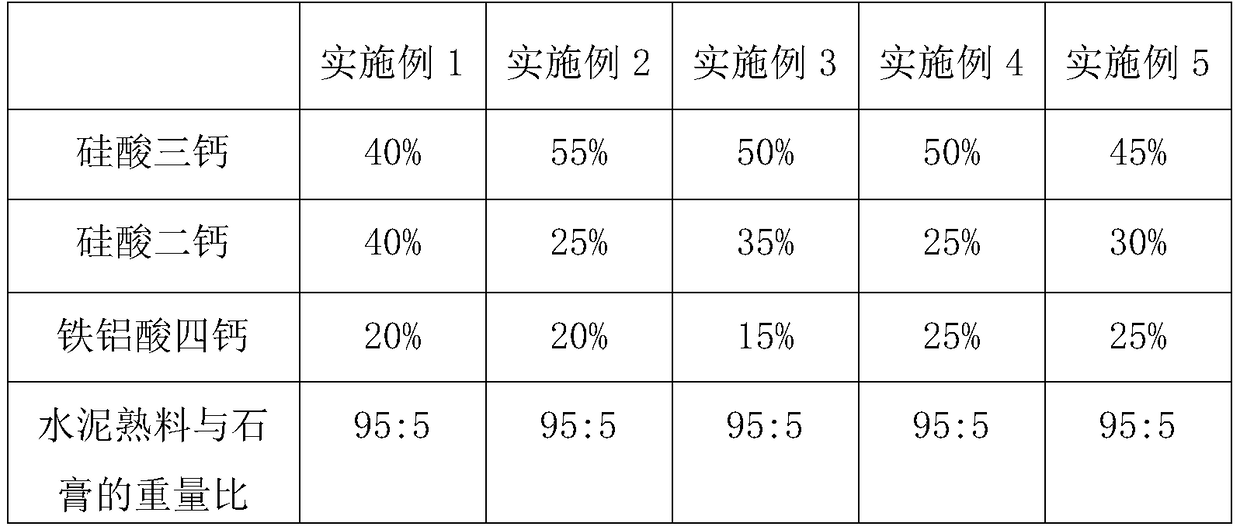

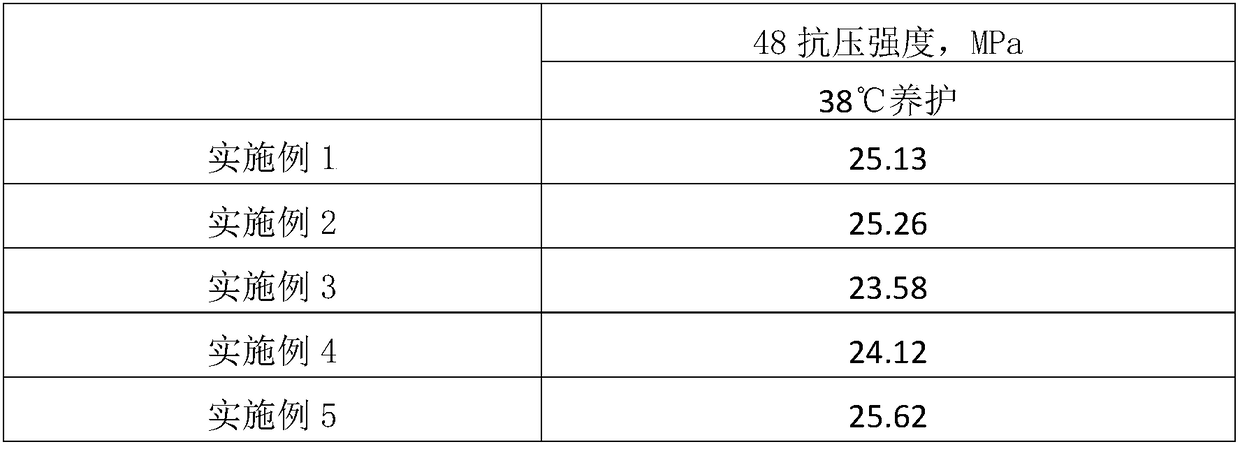

[0037] A kind of shale gas horizontal well cementing cement that one embodiment of the present invention proposes comprises cement clinker and gypsum; The mineral composition of described cement clinker, by weight percentage, it comprises:

[0038] Tricalcium silicate: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com