Additives for cement

A cement composition and calcium sulfoaluminate technology are applied in the field of additives for dicalcium silicate-calcium sulfoaluminate-ferrite cement, and can solve the problems of not being able to obtain modern concrete properties, not being able to provide short-term strength, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0115] Standard mortars are produced according to EN 196 using the following components:

[0116] BCSAF cement (batch 1) 450g

[0117] water 225g

[0118] Standard sand 1350 grams

[0119] BCSAF cement was prepared as described in Example 6 for clinker 2 in Table 7 of US-A-20070266903.

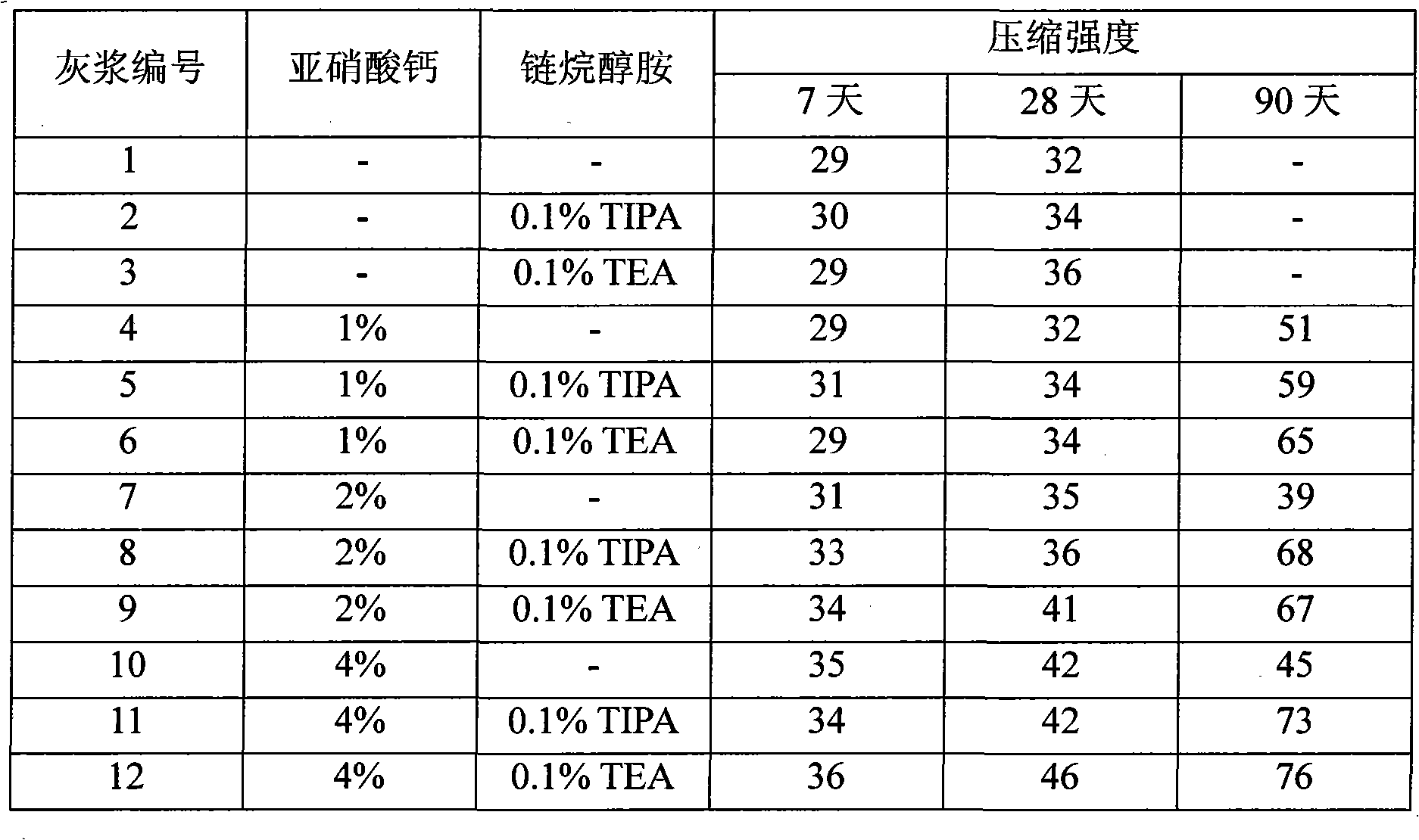

[0120] Alkanolamines (triethanolamine (TEA) or triisopropanolamine (TIPA)) and / or calcium nitrite were included in the mortar samples at the levels indicated in Table 1 below to prepare Mortars 1 to 12. The content of calcium salts is expressed in % dry weight / cement. The content of alkanolamine is expressed in % / mass of cement.

[0121] The compressive strength of the resulting mortar was measured on cylindrical test pieces of 4 x 4 x 16 cm3 prepared using metal molds at 20°C. The samples were stored in water at 20°C for 7 or 28 days until the compressive strength was measured.

[0122] The results obtained are shown in Table 1.

[0123] Table 1

[0124]

[0125] TEA or TIPA alone ...

Embodiment 2

[0130] Standard EN 196 mortars are manufactured using the following components:

[0131] BCSAF cement (batch 1): 315 grams

[0132] Limestone filler: 135g

[0133] Water : 225g

[0134] Sand: 1350g

[0135] (Note: For the purposes of EN 196 mortar formulations, the limestone filler is considered to be part of the cement so that the total cement content is still 450 g)

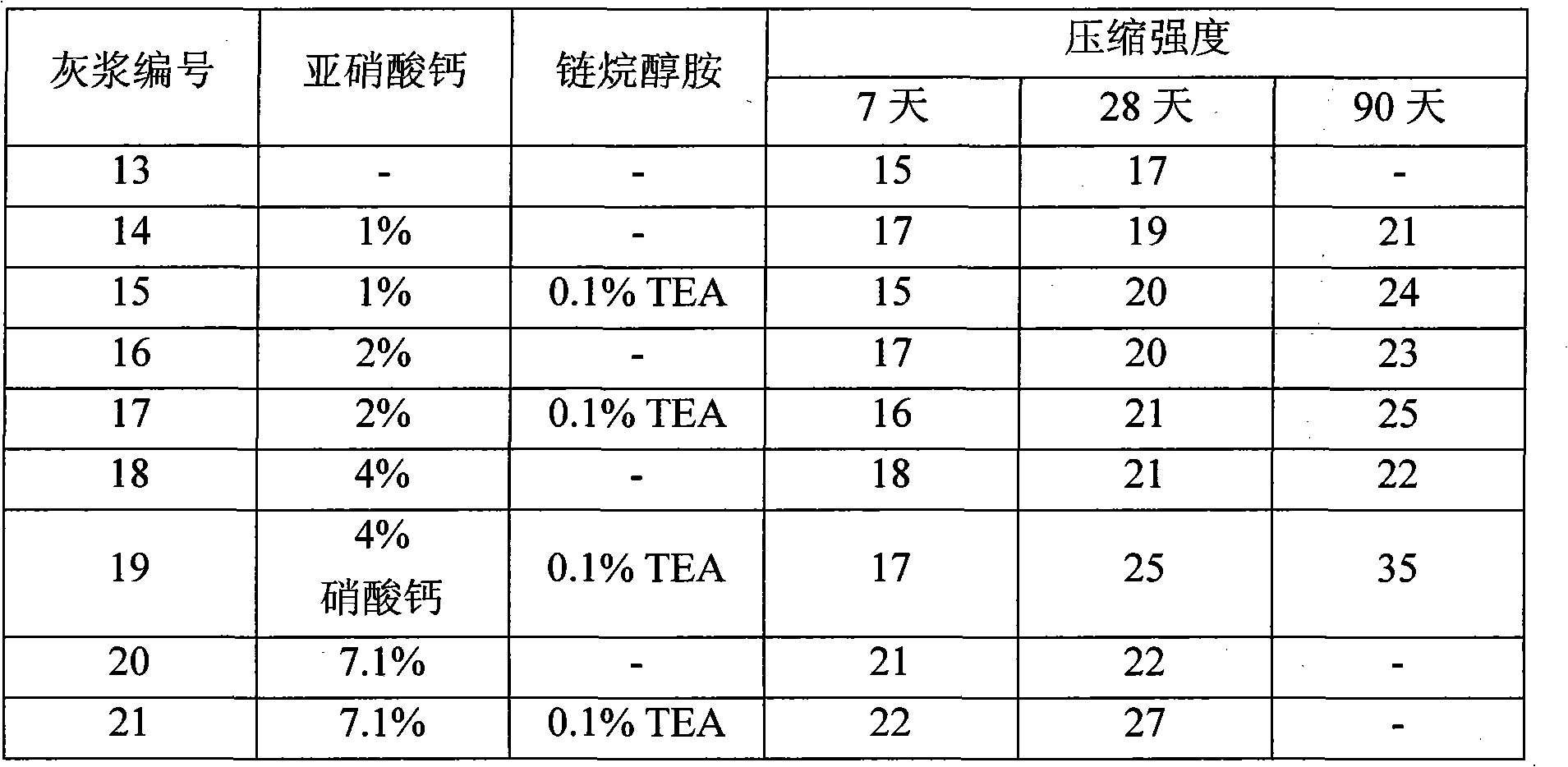

[0136] Alkanolamine, triethanolamine (TEA) or triisopropanolamine (TIPA) and / or calcium nitrite or calcium nitrate were contained in the mortar samples at the contents shown in Table 2 below, thereby preparing mortars 13 to 21. The content of calcium salt is expressed in % dry weight / (cement+filler). The content of alkanolamine is expressed in % / mass of cement+filler.

[0137] The compressive strength of the prepared mortar was measured using the procedure described in Example 1.

[0138] The results obtained are shown in Table 2.

[0139] Table 2

[0140]

[0141] The dosage of calcium nitrate in mo...

Embodiment 3

[0148] Standard mortars are produced according to EN 196 using the following components:

[0149] BCSAF cement (batch 2): 337,5 g

[0150] Limestone filler : 112,5 g

[0151] Water : 225g

[0152] Sand: 1350g

[0153] (Note: For the purposes of EN 196 mortar formulations, the limestone filler is considered to be part of the cement so that the total cement content is still 450 g)

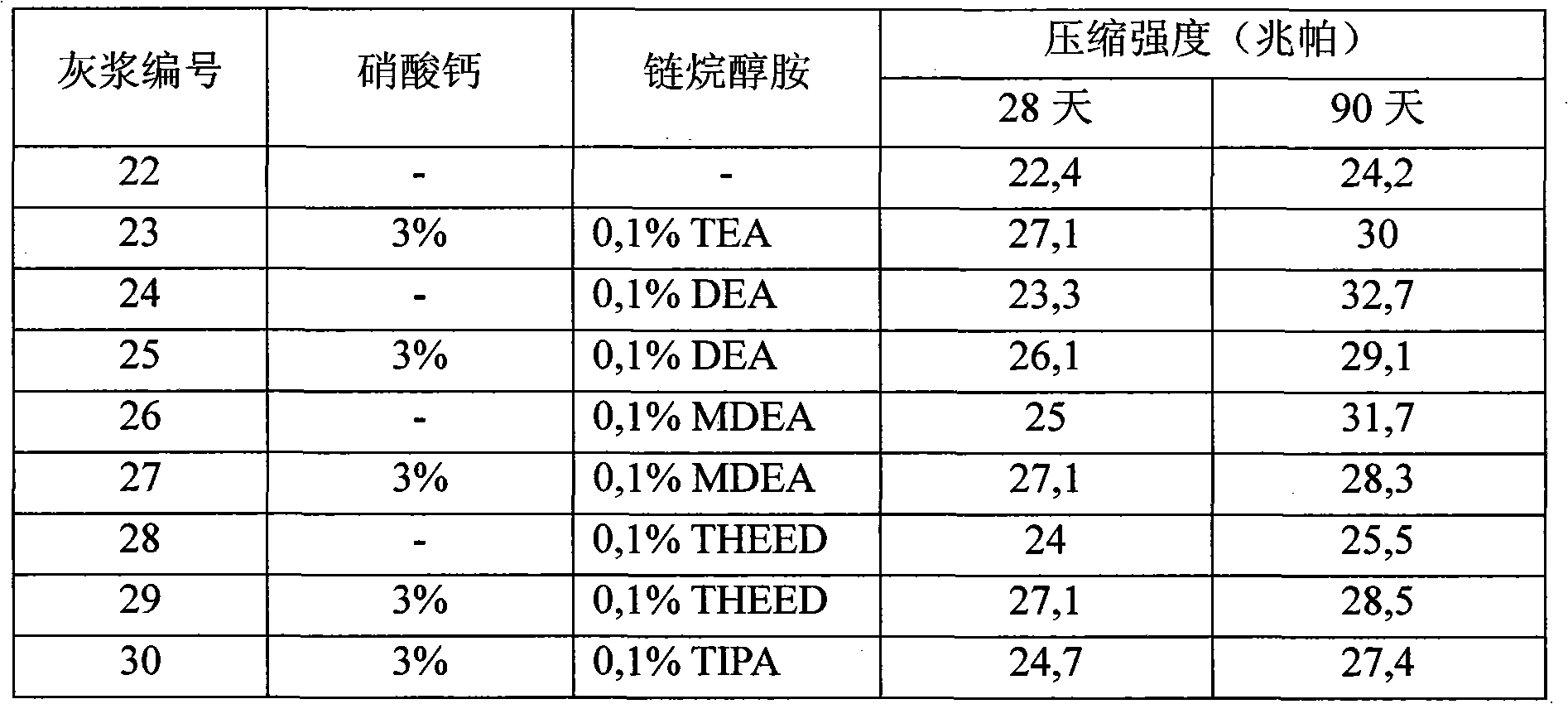

[0154] Alkanolamines, with or without calcium nitrite or calcium nitrate, were included in the mortar samples at levels indicated in Table 3 below to prepare mortars 22 to 30. The content of calcium salt is expressed in % dry weight / (cement+filler). The content of alkanolamine is expressed in % / mass of cement+filler.

[0155] The compressive strength of the prepared mortar was measured using the procedure described in Example 1. The results obtained are shown in Table 3.

[0156] table 3

[0157]

[0158] In the absence of calcium nitrate, MDEA provided a maximum strength increase of 28 da...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com